Automatic detection method for surface damage of conveyor belt

An automatic detection and conveyor belt technology, applied in the direction of optical testing flaws/defects, to avoid frequent start and stop, improve detection quality and efficiency, and reduce mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

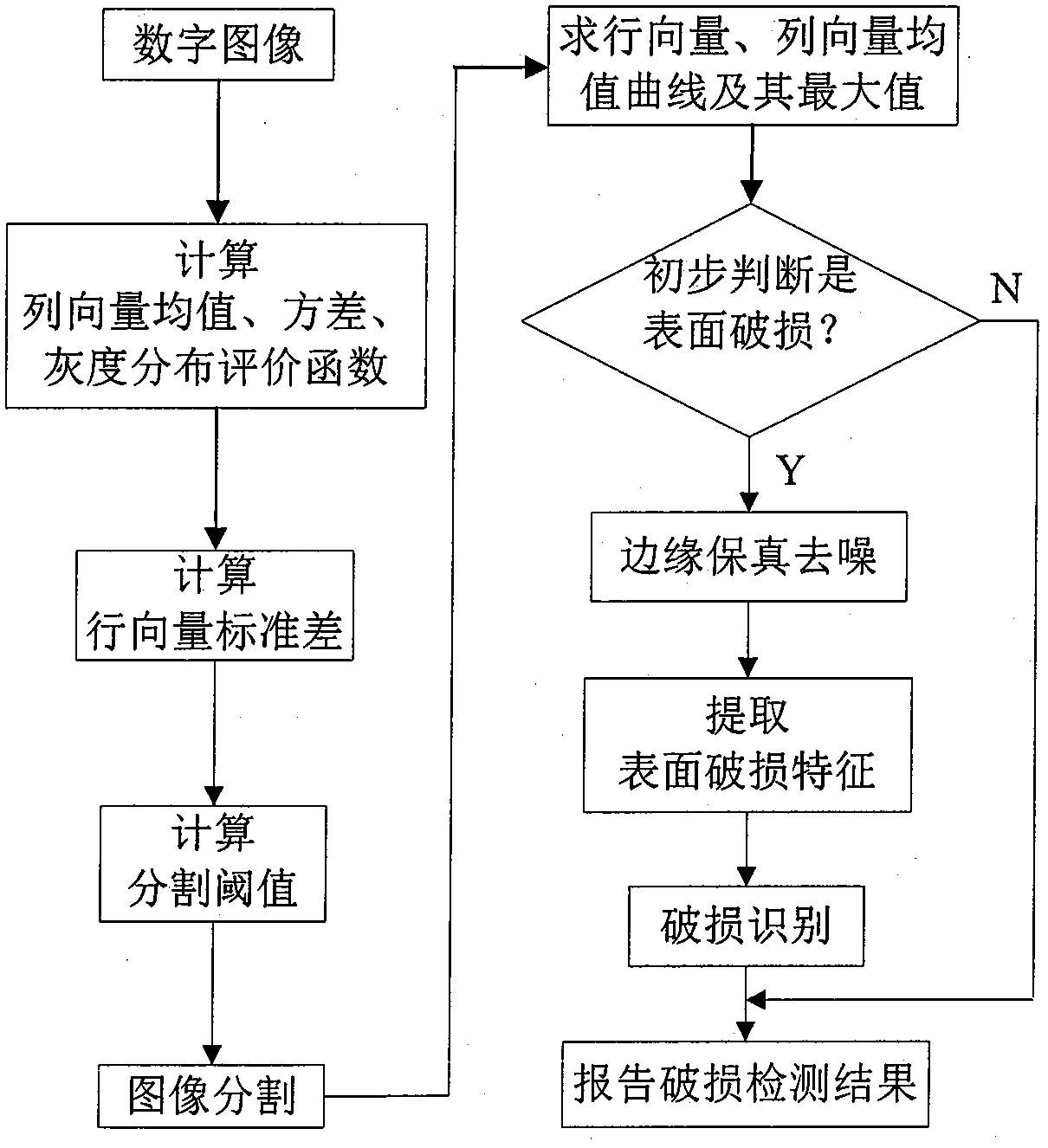

Method used

Image

Examples

example

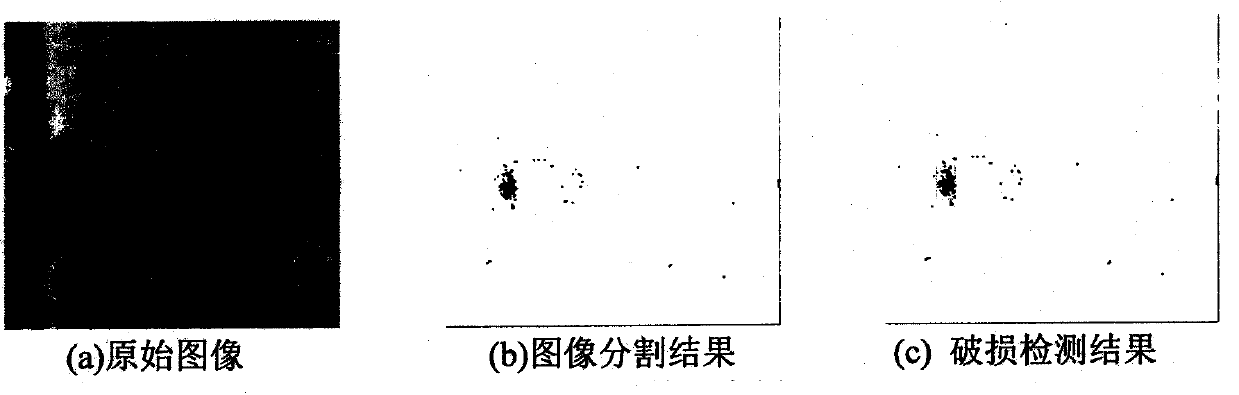

[0064] Example Figure 2(a) has a size of 1024×1024, and the segmented image is Figure 2(b).

[0065] Step 3, calculate the gray average value m of the segmented image, and the row vector average value m R (i),, column vector mean m C ′(j), the maximum value of the row vector mean value R max , column vector mean maximum value C max ;

[0066] The gray average value m of the segmented image, and the row vector average value m R (i), column vector mean m C '(j) and row vector mean maximum value R max , column vector mean maximum value C max The calculation formula is:

[0067]

[0068]

[0069]

[0070] (4)R max =max(|m R (i)|)

[0071] (5)C max =max(|m C '(j)|)

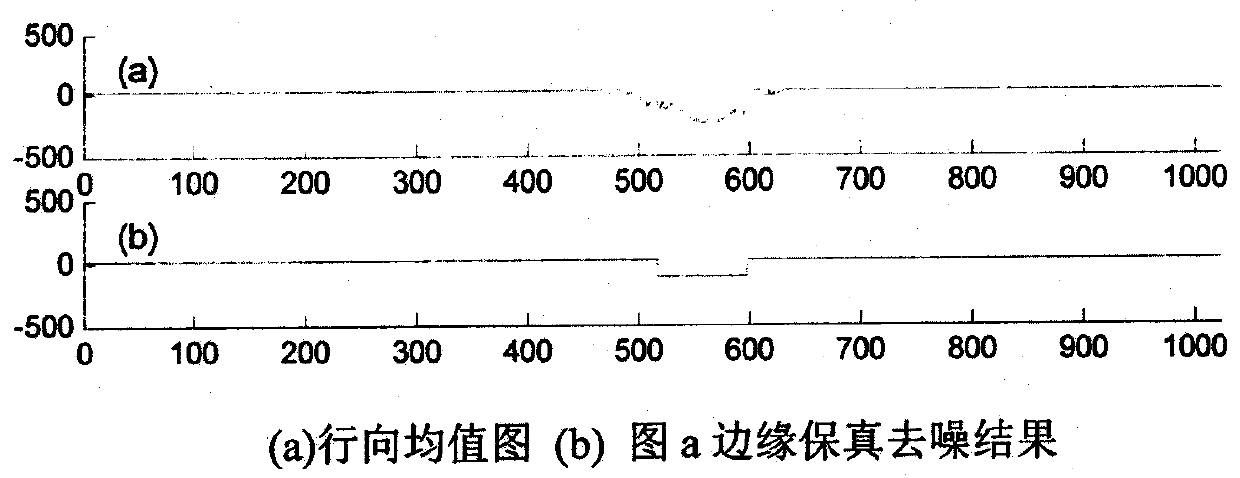

[0072] Example Figure 2(b) row vector, column vector average curve is Figure 3(a), Figure 4(a), R max = 210.15, C max =11.45.

[0073] Step 4, according to the R obtained in step 3 max 、C max , preliminarily judge whether there is damage, if not, go to step 8, otherwise go to step 5;

[0074...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com