High-altitude slipping installation method for compartment-type electric room

An electrical room and sliding technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems that the electrical room cannot be directly lifted, and the construction time is short, so as to achieve uniform stress, improve work efficiency, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

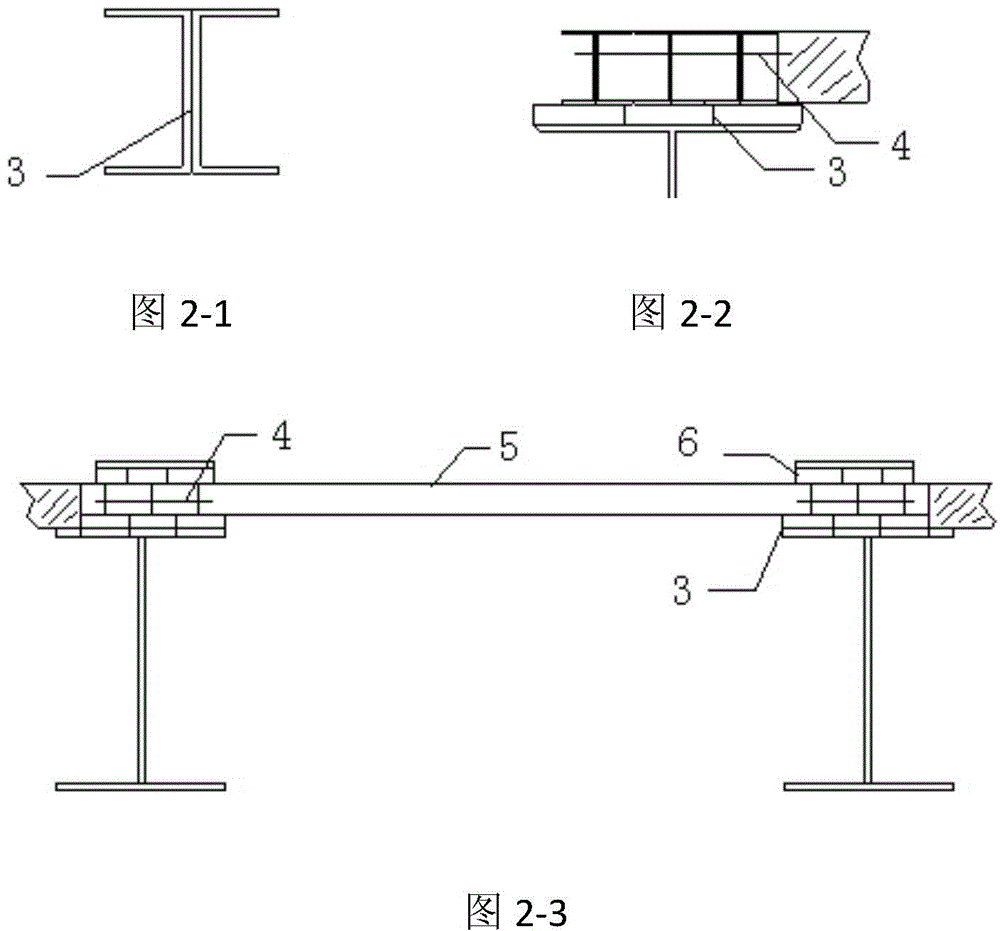

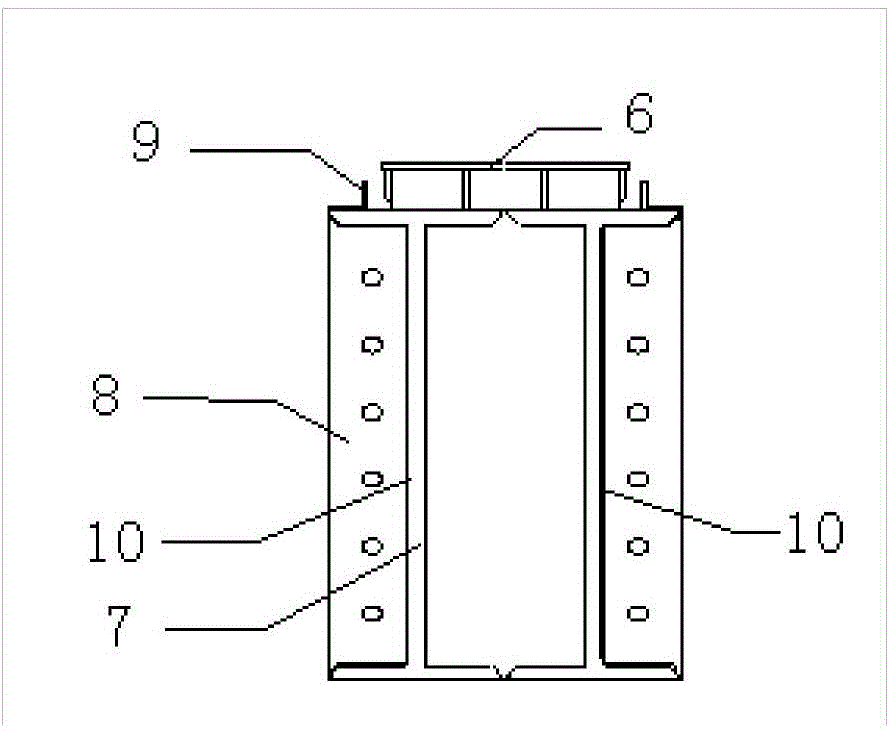

[0018] A high-altitude sliding installation method for a box-type electrical room, comprising the following steps:

[0019] 1. Fabrication and installation of two sliding tracks.

[0020] (1) Manufacture and installation of concrete platform sliding track.

[0021] Production: When the box-type electric room is surrounded by a concrete platform, its installation position is supported by steel beams, and the top surface of the steel beam is lower than the concrete platform, use channel steel to make the sliding track, and make the top surface of the track level with the concrete platform .

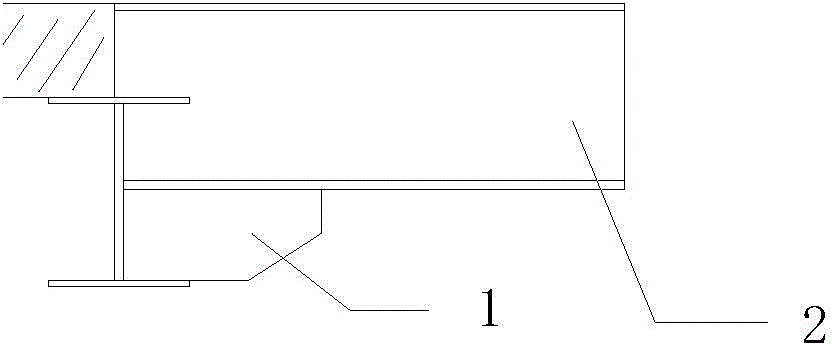

[0022] Such as figure 1 As shown: first, two I-beams 2 are used to form a cantilever beam, and an additional steel plate 1 is installed at the bottom of the I-beam. The function of the cantilever beam is to serve as a support point for the front end of the electrical room when the hoisting of the previous crane is limited, so that the force on the suspension points in front of the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com