Method for arranging anti-buckling energy dissipation structures at root portion and circular steel tube pier

A technology for preventing buckling and energy dissipation, round steel pipe, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of insufficient bending resistance design of bridge piers, troublesome rescue and disaster relief, poor ductility, etc., to shorten the traffic control time, and the construction is convenient and fast. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

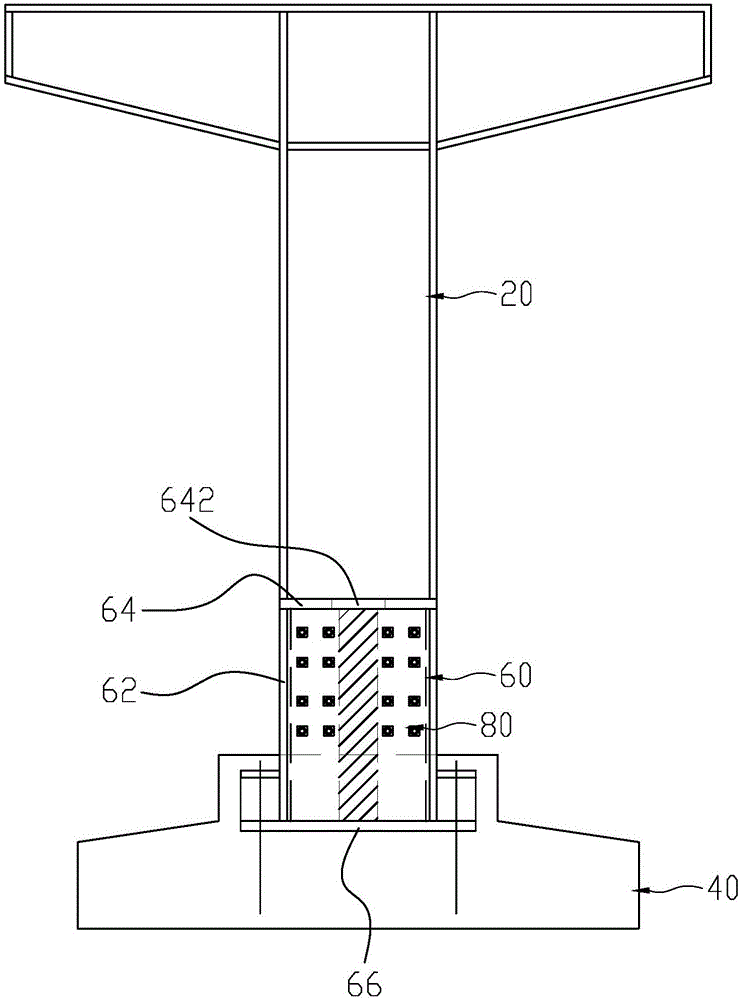

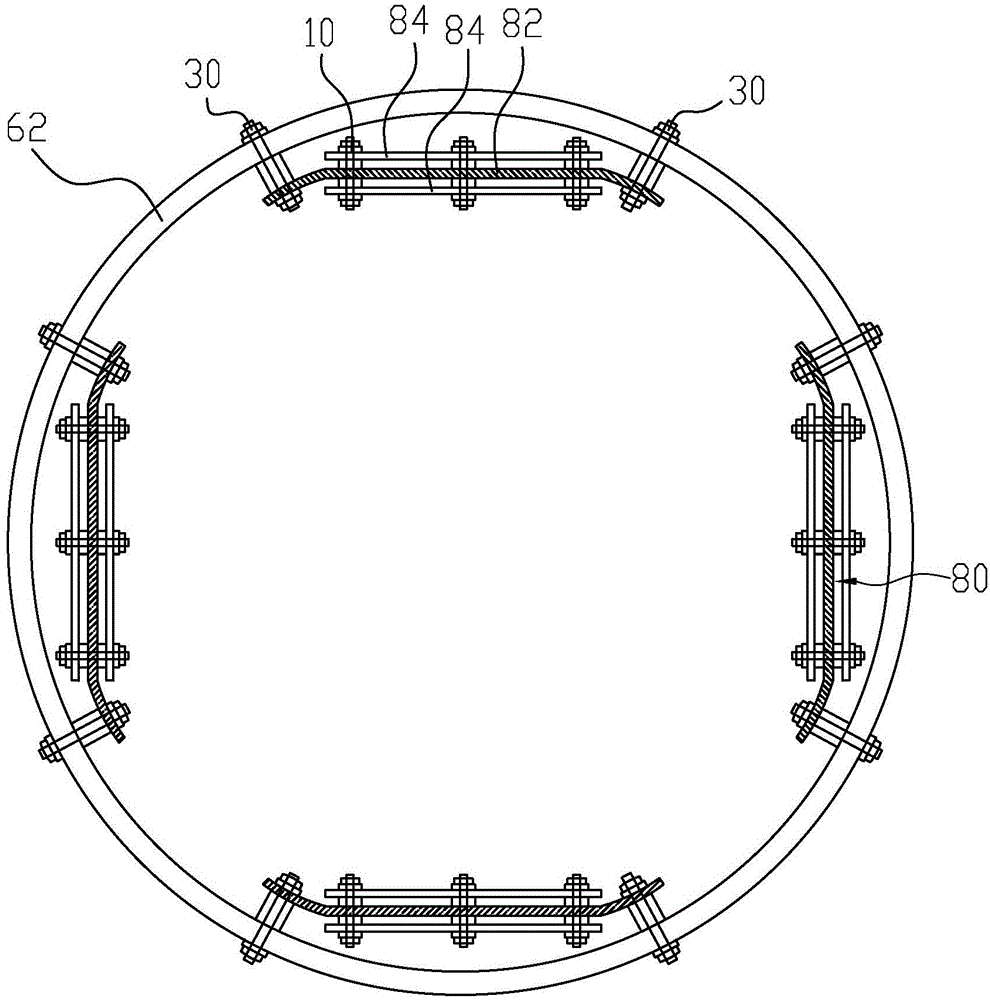

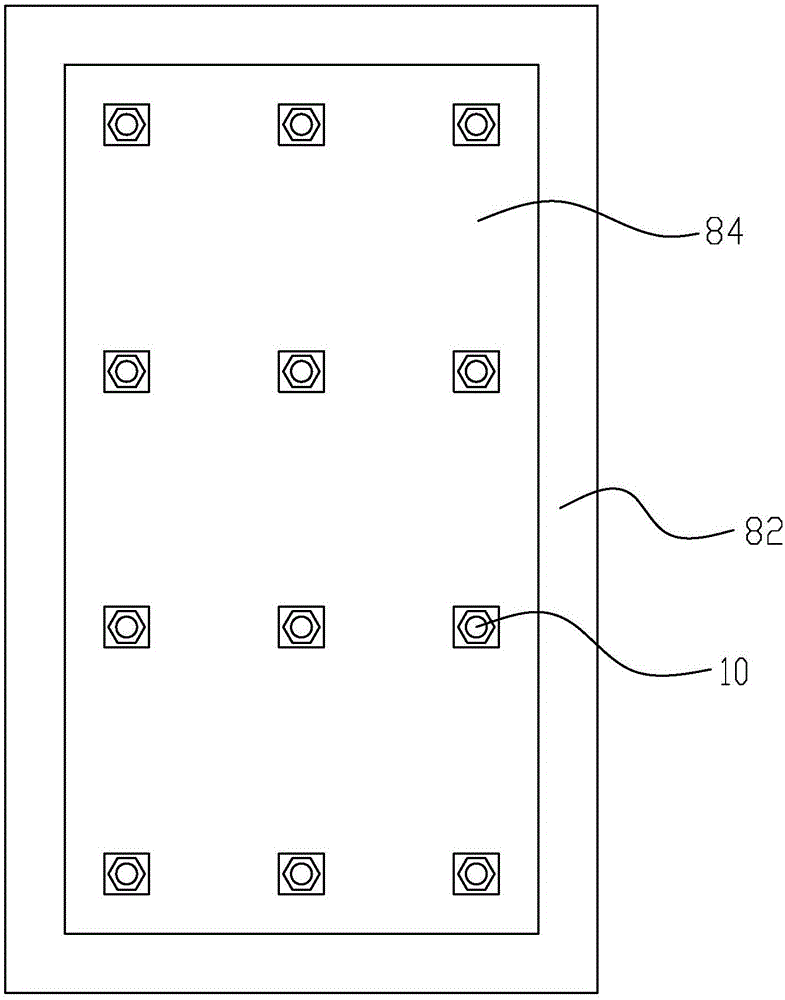

[0027] Please refer to figure 1 , A round steel pipe pier with an anti-buckling energy dissipation structure at the root of the present invention includes an upper pier 20, a base 40, and a lower pier 60 connecting the upper pier 20 and the base 40. The upper pier 20 is surrounded by steel plates into a circular cylindrical structure. The lower pier 60 includes an outer wall 62 surrounded by a high-strength steel plate in a circular cylindrical structure, a transverse partition 64 welded to the top of the outer wall 62 and a bottom plate 66 welded to the bottom of the outer wall 62. The size of the upper pier 20 is the same as the size of the outer wall 62. The diaphragm 64 is welded to the upper pier 20, and the bottom plate 66 is provided with anchor bolt holes (such as Figure 5 (Shown), the bottom plate 66 and the base 40 are locked together. A circular hole 642 is provided in the middle of the transverse partition 64 to facilitate entry and exit of the lower pier 60 (such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com