A heating device for washing and dyeing equipment

A heating device and equipment technology, applied in the direction of processing textile materials equipment configuration, etc., can solve the problems of occupying the inner space of the outer barrel, increasing the inner space of the outer barrel, increasing the water ratio, etc., so as to prolong the service life, reduce the cost of washing and dyeing, The effect of sparing usage ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

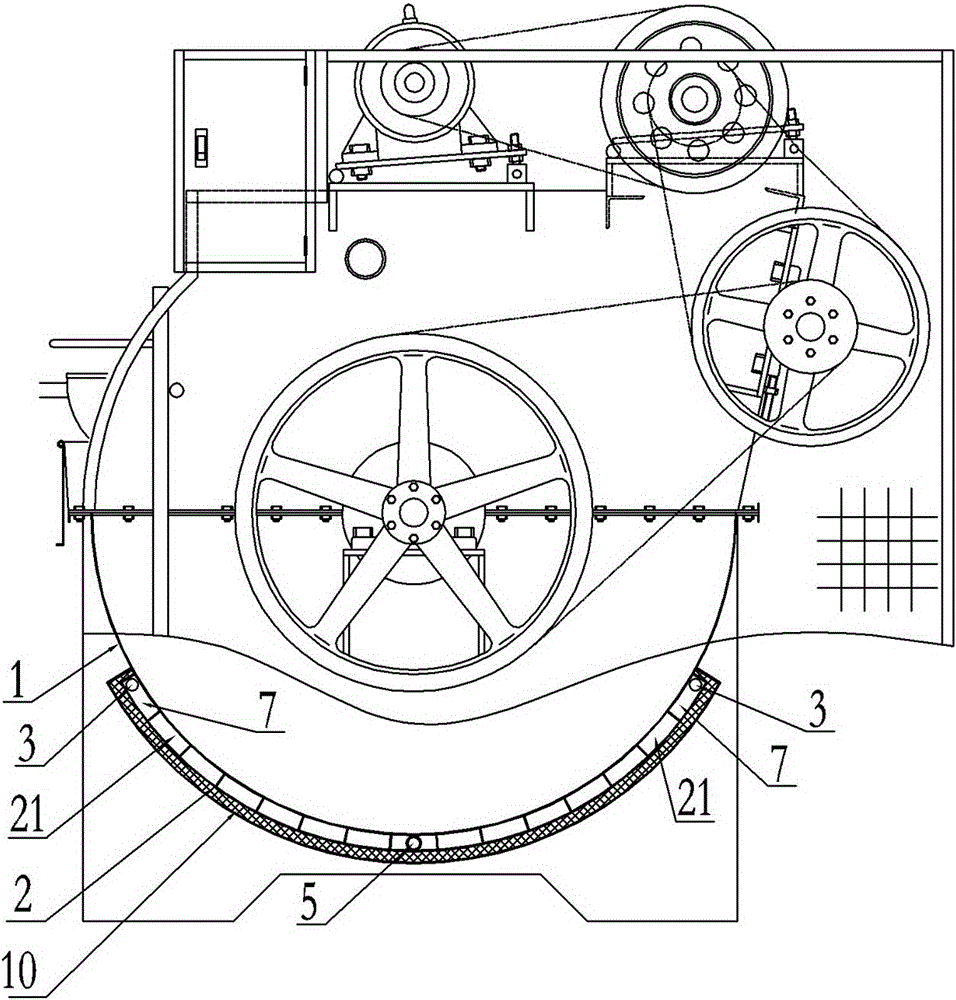

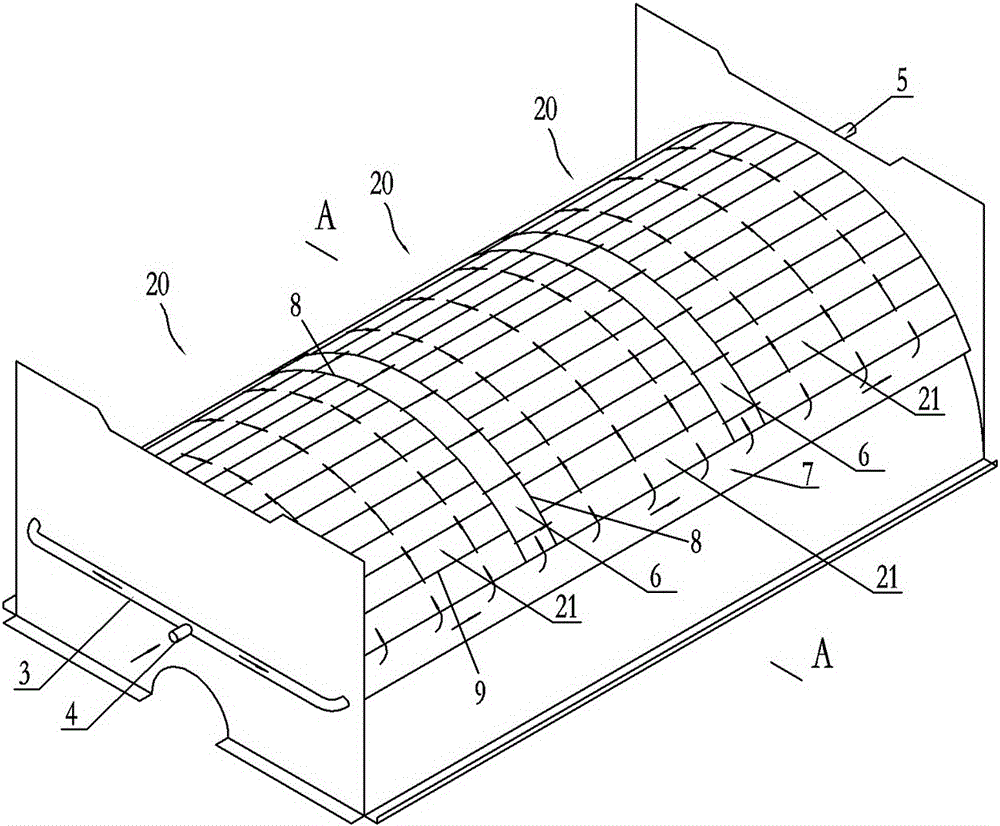

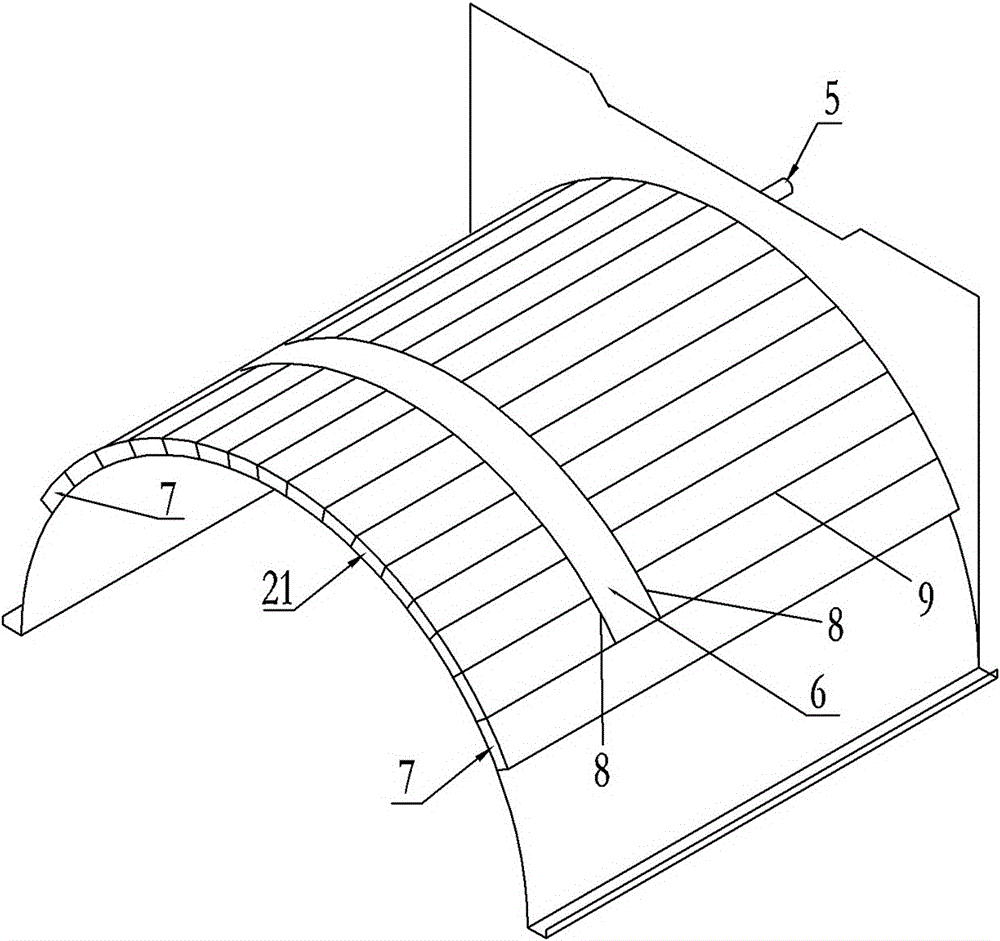

[0011] Such as Figures 1 to 3 As shown, it is located on the outside of the outer barrel 1, and includes an arc-shaped heating cavity 2 wrapped around the bottom of the outer wall of the outer barrel 1. The inner space of the arc-shaped heating cavity 2 is separated by a circumferential partition 8 to form a plurality of The heating zones 20 arranged at intervals along the axial direction, and the circumferential partitions 8 form spacers 6 between adjacent heating zones 20; the tops of both sides of each heating zone 20 are provided with air intake channels 7, and the air intake channels 7 communicate with the top of each heating zone 20 respectively; each heating zone 20 is provided with a plurality of axial partitions 9 to divide the heating zone 20 into a plurality of axially extending sub-regions 21, and the walls of each adjacent sub-region 21 There are through holes connecting the adjacent sub-areas, so that the steam in the adjacent sub-area can enter the next sub-are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com