Cement-based concrete reinforcing bar antirust paint, preparation method and application thereof

A concrete reinforcement and cement-based technology, applied in cement coatings, anti-corrosion coatings, coatings, etc., can solve problems such as unsatisfactory anti-rust effects, and achieve the effect of large-scale construction, cheap raw materials, and excellent anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

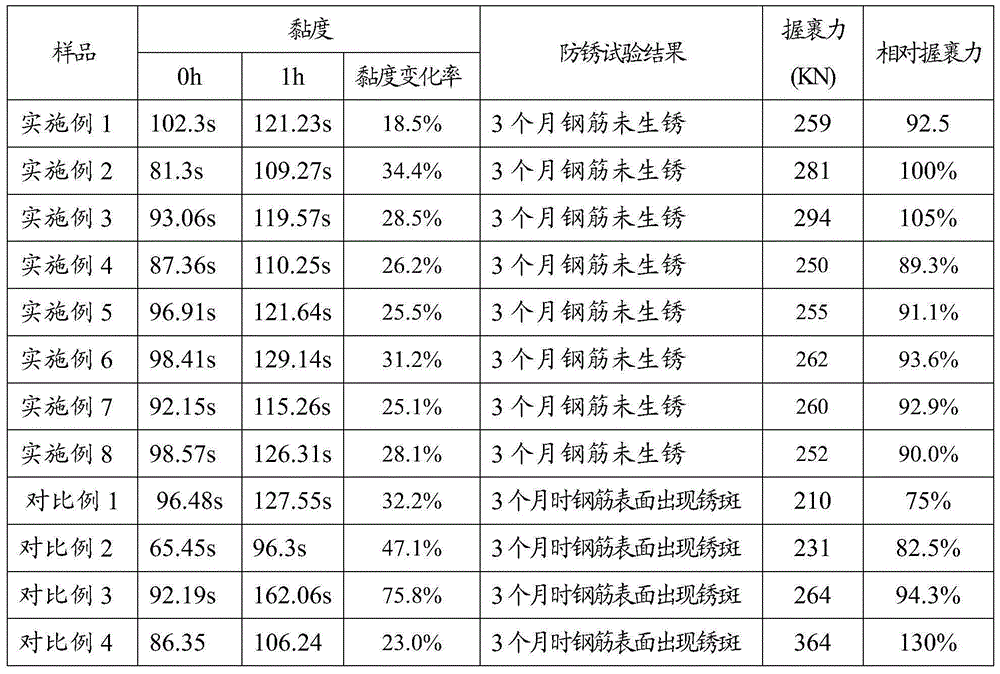

Examples

Embodiment 1

[0043] Example 1 A cement-based coating for rust prevention of concrete reinforcement

[0044] The raw material composition is:

[0045] 1kg (100%) of ordinary Portland cement with strength grade 52.5, 20g (2%) of RI steel rust inhibitor, 200g (20%) of ethylene-vinyl acetate copolymer, 9g (0.9%) of naphthalene-based powder water reducer, Sodium lignosulfonate 2g (0.2%), water 550g (55%).

[0046] Prepared by:

[0047] I. Prepare the above-mentioned various raw materials according to the formula;

[0048] II. Turn on the automatic mode of the mixer, add naphthalene-based powder water reducer and water, and stir for 2 minutes to fully mix the naphthalene-based powder water-reducer and water;

[0049] III. Add ethylene-vinyl acetate copolymer to the mixer, and continue to stir automatically for 2 minutes to obtain a uniform emulsion;

[0050] IV. Add cement and RI steel rust inhibitor to the emulsion obtained in step III, add sodium lignosulfonate after automatic stirring for ...

Embodiment 2

[0051] Example 2 A cement-based coating for rust prevention of concrete reinforcement

[0052] The raw material composition is:

[0053] Ordinary Portland cement of strength grade 52.5 1kg (100%), RI steel rust inhibitor 20g (2%), ethylene-vinyl acetate copolymer 150g (15%), naphthalene-based powder water reducer 10g (1%), Sodium lignosulfonate 2g (0.2%), water 500g (50%).

[0054] Preparation method: the same operation and steps as described in Example 1.

Embodiment 3

[0055] Example 3 A cement-based coating for rust prevention of concrete reinforcement

[0056] The raw material composition is:

[0057] Ordinary Portland cement of strength grade 52.5 1kg (100%), RI steel bar rust inhibitor 20g (2%), ethylene-vinyl acetate copolymer 136g (13.6%), naphthalene-based powder water reducer 10g (1%), Sodium lignosulfonate 1.8g (0.18%), water 467g (46.7%).

[0058] Preparation method: the same operation and steps as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com