Garbage fly ash water washing liquid evaporation desalination system and method

A garbage fly ash and water washing technology, applied in the field of evaporative desalination, can solve the problems of high salt concentration, low evaporation capacity, and poor salt output, and achieve the effect of high separation efficiency, large evaporation capacity, and smooth salt output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

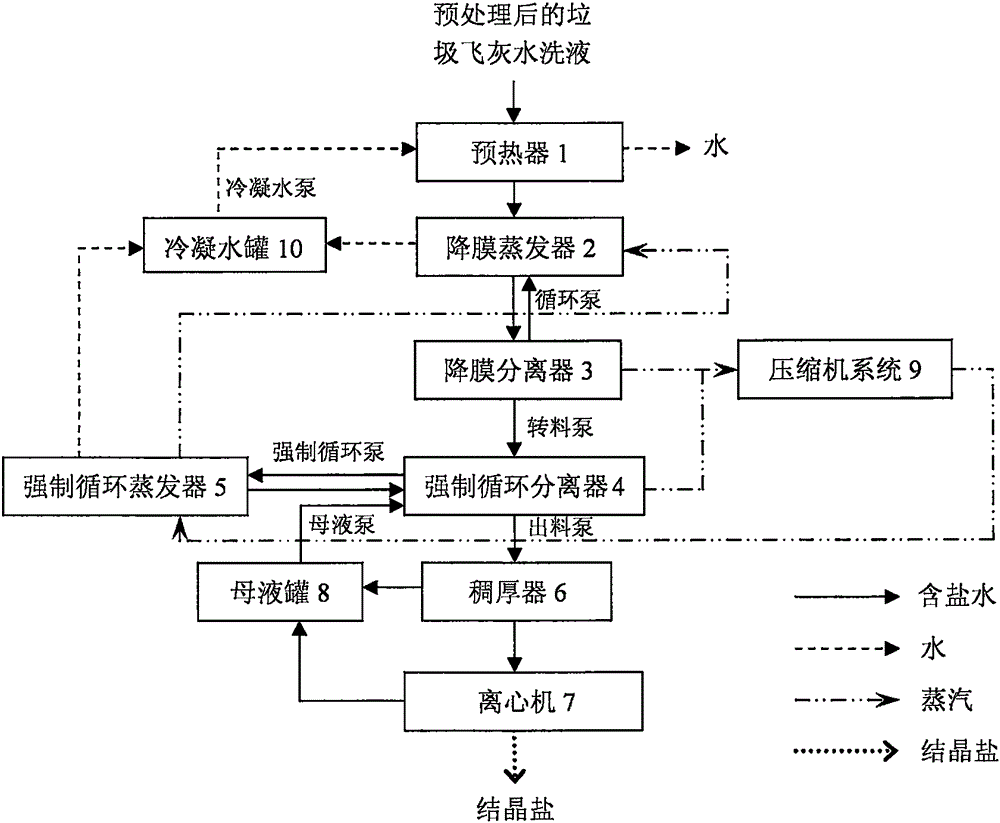

[0039] A method for evaporating and desalting garbage fly ash water washing liquid, comprising the steps of:

[0040] 1) Turn on the feed pump, inject the pretreated garbage fly ash washing solution with a salt concentration of 8% into the preheater for heating, the heating medium is condensed water after heat exchange, and control the material temperature after heating to ≥95° ;

[0041] 2) After preheating, the material enters the falling film evaporator for evaporation and concentration, and the evaporation temperature in the falling film evaporator is controlled to be 103-104°C;

[0042] 3) After evaporation and concentration, the material with a salt concentration of 20-27% enters the falling film separator for gas-liquid separation. After separation, the steam enters the compressor system. After separation, part of the liquid returns to the falling film evaporator through the circulating pump to continue evaporation, and the other part It is pumped into the forced circu...

example 2

[0048] A method for evaporating and desalting garbage fly ash water washing liquid, comprising the steps of:

[0049] 1) Turn on the feed pump, inject the pretreated garbage fly ash washing solution with a salt concentration of 10% into the preheater for heating, the heating medium is condensed water after heat exchange, and control the material temperature after heating to ≥95° ;

[0050] 2) After preheating, the material enters the falling film evaporator for evaporation and concentration, and the evaporation temperature in the falling film evaporator is controlled at 105-106°C;

[0051] 3) After evaporation and concentration, the material with a salt concentration of 20-27% enters the falling film separator for gas-liquid separation. After separation, the steam enters the compressor system. After separation, part of the liquid returns to the falling film evaporator through the circulating pump to continue evaporation, and the other part It is pumped into the forced circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com