Electric feedback quantitative filling valve

A filling valve, electric feedback technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problem of inaccurate filling level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

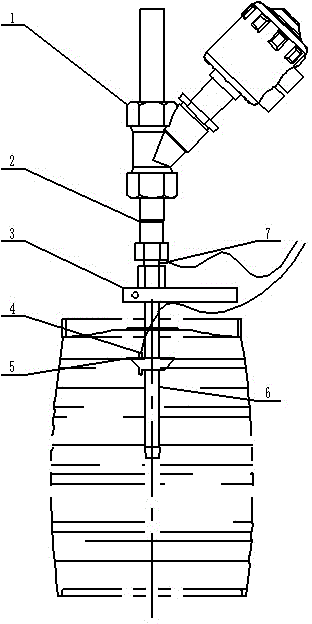

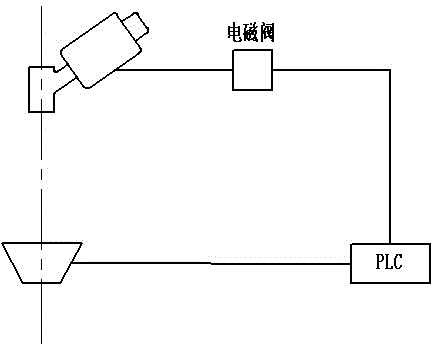

[0005] The present invention is described in detail as follows with reference to the drawings in the specification: the working process is: the pipeline connects the angle seat valve and the filling head together; ;The negative terminal is installed on the insulating rubber sleeve, and the positive and negative terminals are connected to the PLC; the insulating rubber sleeve is set on the filling head and can move up and down along the filling tube of the filling head; Lifting tables are partially connected. Using the conductivity of the filling liquid, the negative terminal is in contact with the liquid in the filling head. When the liquid level reaches a certain height, the liquid is in contact with the positive terminal, the circuit forms a path, and the electrical signal is transmitted to PLC, PLC By controlling the solenoid valve and then controlling the angle seat valve to close it, the quantitative filling is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com