Solar cell module synchronous turnover device

A technology of solar cells and turning devices, applied in the directions of lifting devices and hoisting devices, can solve the problems of high labor intensity of workers, loose components, bumped or damaged components, etc., and achieve easy maintenance and adjustment, accurate turning angles, and avoidance of The effect of the tray falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

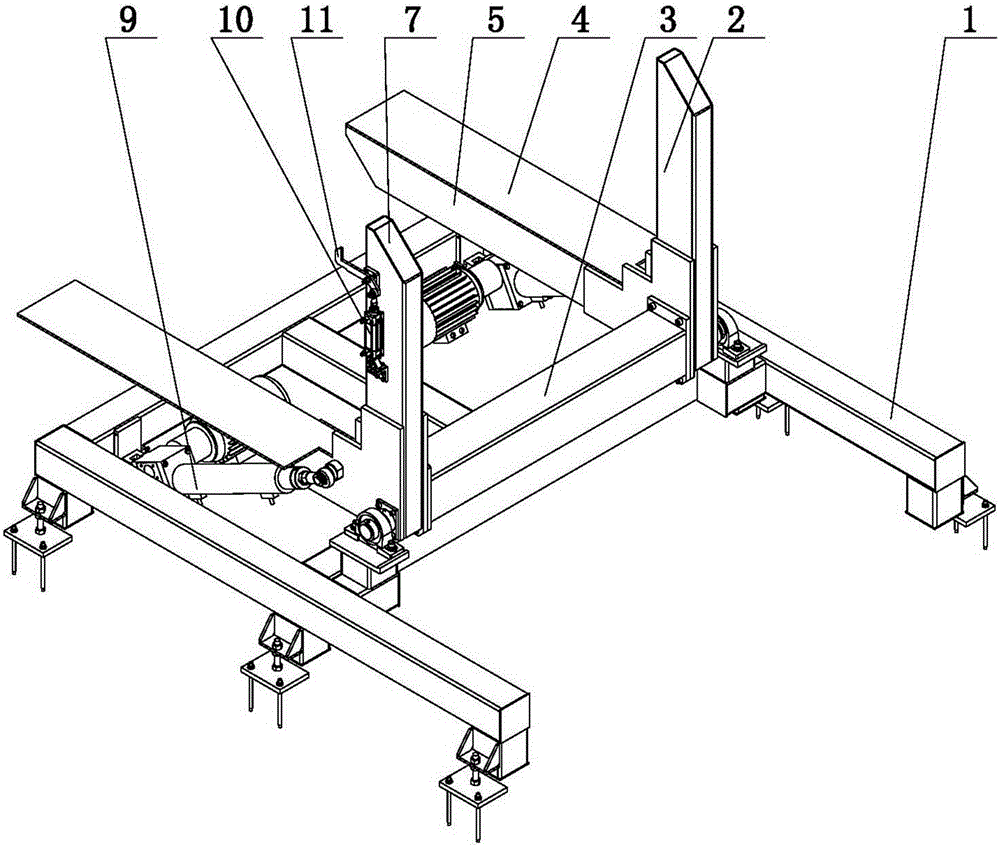

[0017] The present invention includes a frame 1, which is characterized in that an L-shaped overturning frame 7 is arranged on the frame 1 through a rotating shaft 6, and an overturning power device 9 of the overturning frame 7 is arranged on the frame 1.

[0018] As a preferred solution of the present invention, a stepped support portion 8 is provided at the corner of the L-shaped overturning frame 7 .

[0019] As another preferred solution of the present invention, the L-shaped overturn frame 7 is composed of a feed end support 5 and a discharge end support 2 that are perpendicular to each other; the end of the discharge end support 2 is set by a fixed shaft 12 There is a hook 11; the end of the hook 11 is connected with the piston rod 13 of the cylinder 10; the end of the cylinder 10 is hinged with the support 2 of the discharge end. The vertically placed tray 15 can be fixed by the hook 11 to avoid interference when the solar battery module 14 is turned over.

[0020] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com