Gravity self-adaption elevator for LED television production line

A technology for LED TVs and production lines, applied in the field of elevators, can solve problems affecting the efficiency of the production line, constant counterweight weight, and increased energy consumption, and achieve the effects of low assembly processing and post-maintenance costs, high reliability, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

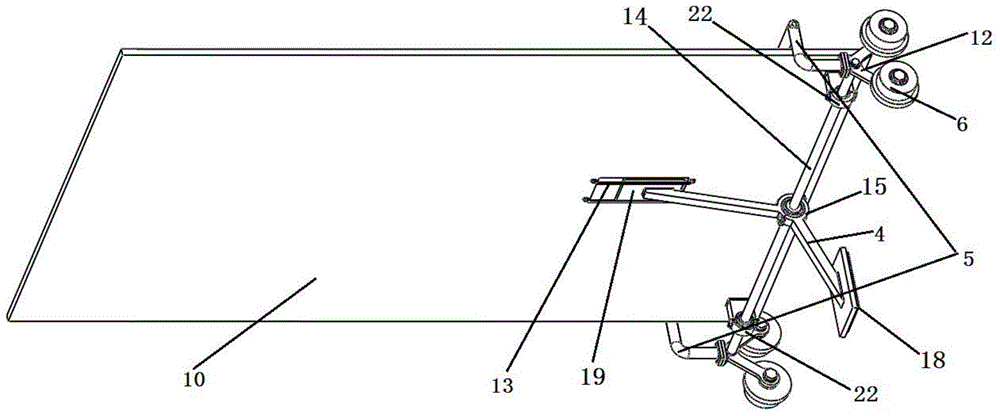

[0035] see figure 1 , figure 2 and image 3 . A gravity self-adaptive lift for an LED TV production line, comprising a base plate 1, a longitudinal support 2, a fixed friction plate 3, a herringbone friction strut 4, a lateral support 7, a lifting motor 8, a motor support bar 21, and a cargo platform 10 , cable 9, cross bar 14, roller 6, Z-shaped lever 5 and V-shaped connecting rod 12. The two longitudinal supports 2 and the lower end of the fixed friction plate 3 are fixedly mounted on the bottom plate 1 by means of bolts. One end of the cable 9 is connected to the hoisting motor 8 and the other end is connected to the load platform 10 .

[0036] join figure 1 and Figure 4 , the hoisting motor 8 is fixedly installed on the two motor support bars 21 by bolts, the motor support bars 21 are fixed on the two transverse brackets 7 by bolts, the transverse bracket 7 is fixedly installed on the wedge block 20 by bolts, and the wedge block 20 is inserted into In the rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com