Reprocessing traction device

A traction device and frame technology, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of low efficiency and high labor intensity, and achieve the effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

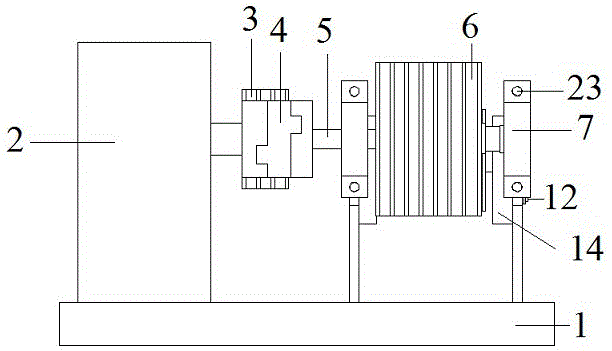

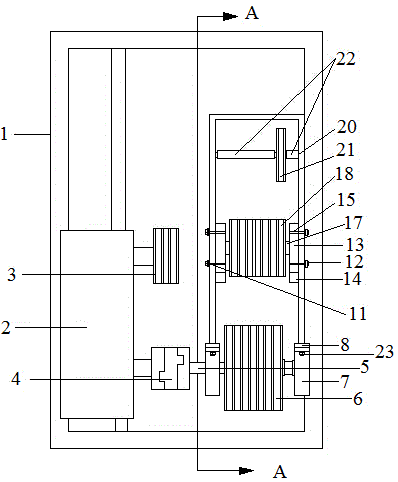

[0012] exist Figure 1 to Figure 4 Among them, this carriage return traction device includes a frame 1, which is characterized in that a reducer 2 is installed on the left side of the frame 1, a first pulley 3 is provided on the right side of the front part of the reducer 2, and a power is provided on the right side of the rear part of the reducer 2. The output shaft 3 and the power output shaft 3 are connected with the driving steel rope wheel shaft 5 through the cross coupling 4, the driving steel cable wheel shaft 5 is connected with the driving steel cable wheel 6 through a key, and the driving steel cable wheel shaft 5 has a bearing housing 7 with bearings The first iron block 8 is welded on the frame 1 on both sides of the active steel rope wheel 6, and there are two first through holes 9 on the first iron block 8, and there is a square concave hole at the connection between the first iron block 8 and the frame 1. Groove 10, the bearing housing 7 with bearing is vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com