Automatic Assembly System of Spacecraft Modules on the Ground

An assembly system and spacecraft technology, applied in aircraft assembly and other directions, can solve problems such as poor stability and low docking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

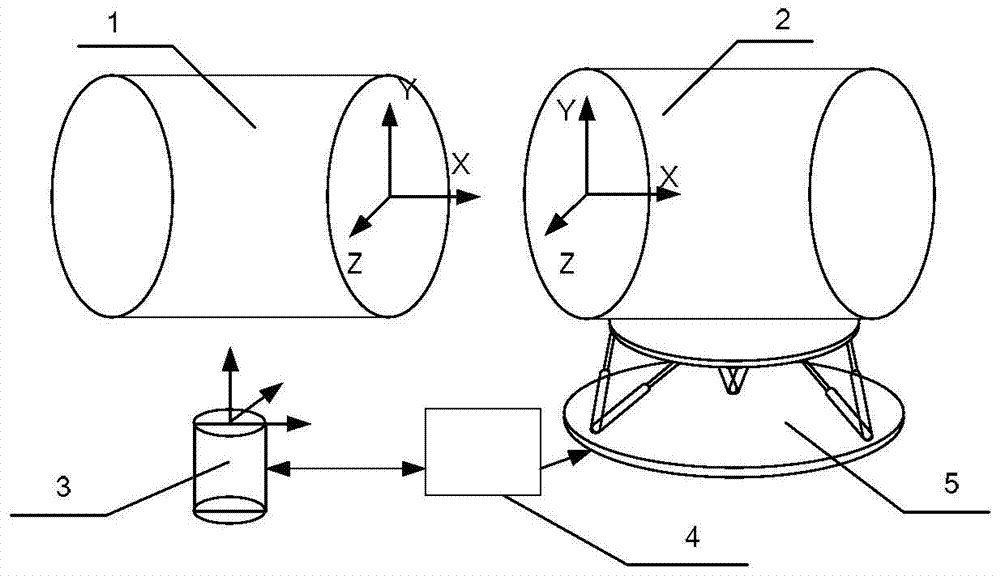

[0075] Embodiment 1: Combining figure 1 and figure 2 Describe this embodiment, describe this embodiment, the automatic assembly system of the spacecraft module on the ground described in this embodiment, the assembly system includes a master control system 4, a laser tracker 3 and a parallel mechanism 5;

[0076] The master control system 4 is used to control the laser tracker 3, and according to the position information measured by the laser tracker 3, obtain the positions of the fixed section end face 1, the moving section end face 2 and the parallel mechanism 5 of the cabin section, and according to the obtained position information, Calculate the relative position data of the end face 1 of the fixed segment and the end face 2 of the moving segment, and control the parallel mechanism 5 according to the relative position data;

[0077] The laser tracker 3 is used to measure the position information of the end face 1 of the fixed segment, the end face 2 of the moving segmen...

specific Embodiment approach 2

[0082] Embodiment 2: This embodiment is a further limitation of the automatic assembly system of the spacecraft module on the ground described in Embodiment 1. The general control system 4, according to the obtained position information, controls the parallel mechanism 5 to include: :

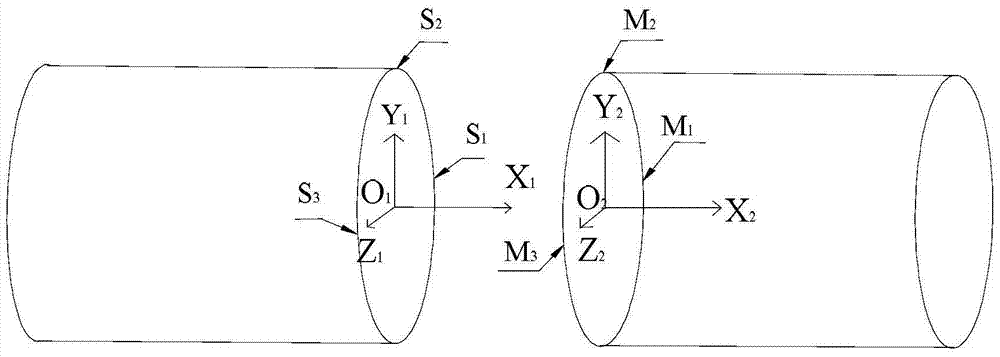

[0083] According to the obtained position information, establish the calibration coordinate system O of the end face 1 of the fixed segment 1 -X 1 Y 1 Z 1 and the calibration coordinate system O of the end face 2 of the moving segment 2 -X 2 Y 2 Z 2 ;

[0084] According to the obtained position information, the coordinate system O of the parallel mechanism 5 when the parallel mechanism 5 rotates in three dimensions is established 3 -X 3 Y 3 Z 3 ;

[0085] When the distance from the origin of the coordinate system between the end face 1 of the fixed segment and the end face 2 of the moving segment is greater than or equal to (l+dl) mm, the calibration coordinate system of the end fac...

specific Embodiment approach 3

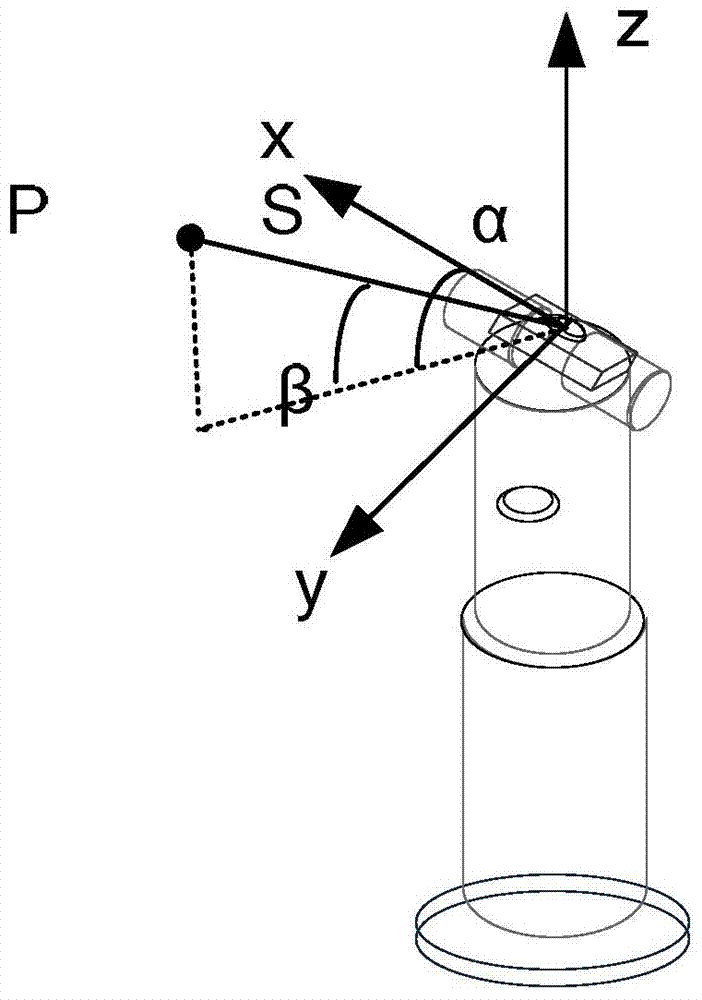

[0092] Specific implementation three: combination image 3 This embodiment is described. This embodiment is a further limitation of the automatic assembly system of the spacecraft module on the ground described in the second embodiment. The laser tracker 3 is used to measure the end faces 1 and 1 of the fixed segment by using the target ball. The position information of the end face 2 of the moving segment includes:

[0093] After the target ball is measured, the three-degree-of-freedom coordinates of the center of the target ball are output;

[0094] The end face 1 of the fixed section and the end face 2 of the moving section are both planes, and three reference points are respectively selected on the end face 1 of the fixed section and the end face 2 of the moving section, and a target ball is fixed on each of the selected reference points;

[0095] The general control system 4, according to the obtained position information, establishes the calibration coordinate system O ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com