Bus skeleton

A bus and skeleton technology, applied to vehicle parts, load-bearing body structure, upper structure of passenger cars, etc., can solve the problems of inconvenient passengers getting on and off, affect the performance of the body, increase the height of the body, etc., and achieve structural strength strengthening and shape lines Smooth, weight-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

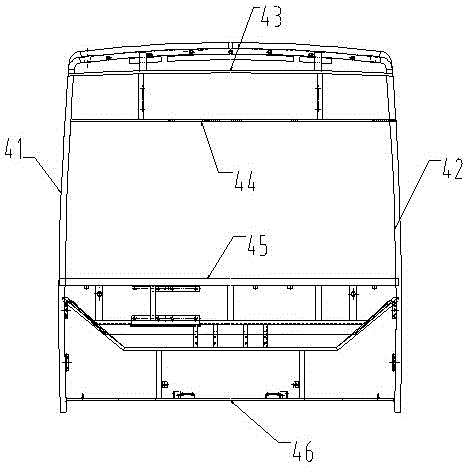

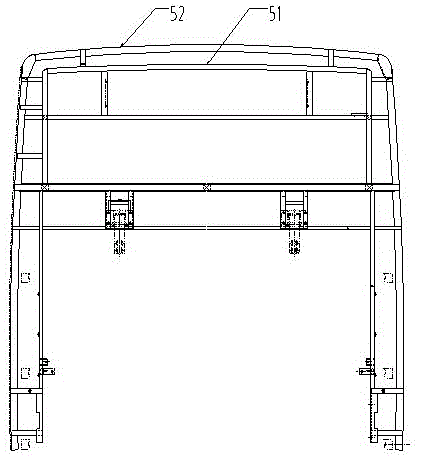

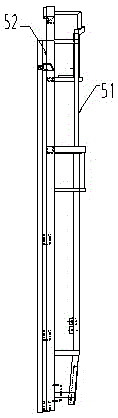

[0076] Such as figure 1 In the bus frame shown, the columns of the technical solution of the present invention include the first column 41 and the second column 42, and the beams include the first beam 43, the second beam 44, the third beam 45 and the fourth beam 46. Column 41 and No. 2 column 42 are arranged in parallel, No. 1 beam 43, No. 2 beam 44, No. 3 beam 45, and No. 4 beam 46 are arranged from top to bottom between No. 1 column 41 and No. 2 column 42, and No. 1 The two ends of the cross beam 43, the second cross beam 44, the third cross beam 45 and the fourth cross beam 46 are vertically connected to the first column 41 and the second column 42 respectively. The top of the first cross beam 43 is provided with an arc-shaped aluminum profile. The two ends of the profile are respectively fixedly connected to the tops of the first column 41 and the second column 42.

[0077] A bus windshield installation area is formed between the second cross beam 44 and the third cross ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com