Cable tinning equipment

A cable and tin dipping technology, applied in welding equipment, metal processing equipment, tin feeding devices, etc., can solve the problems of inconsistent position and length of tin dipping, affecting product quality, low processing efficiency, etc. Tin effect, easy operation, and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

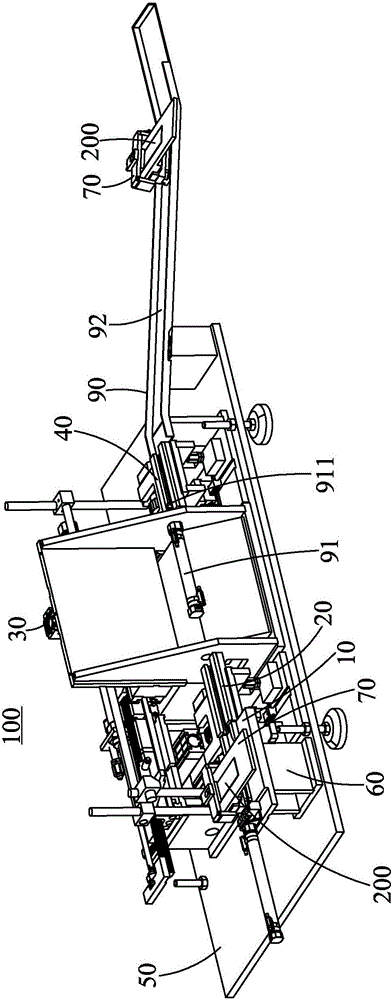

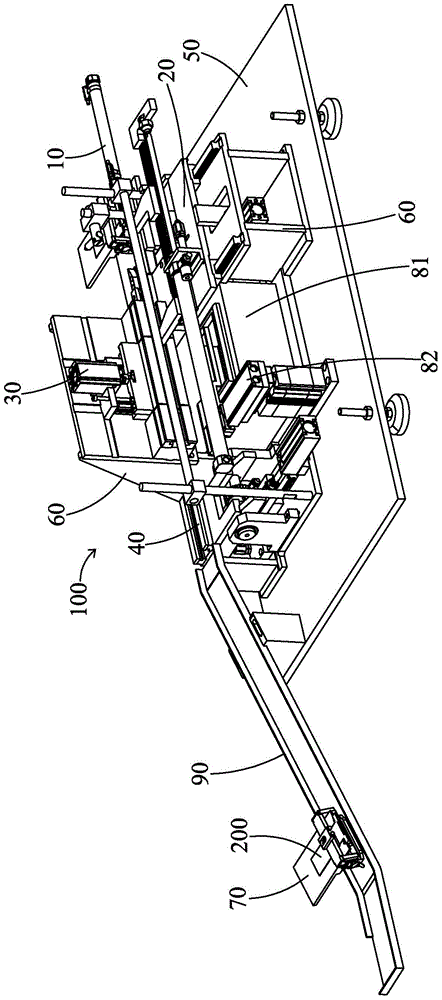

[0017] see Figure 1 to Figure 4 As shown, the cable tinning equipment 100 of the present invention is used to dip the head of the cable 200 into the tin furnace 81 for tinning, which includes first, second, third, and fourth feeding mechanisms 10, 20, 30, 40 , Base 50, bracket 60, carrier 70, tin furnace 81, tin scraping mechanism 82 and receiving mechanism 90. The first, second, third, and fourth feeding mechanisms 10, 20, 30, and 40 are docked in sequence from front to back, and are respectively arranged on the bracket 60, the bracket 60 is fixed on the base 50, and the carrier 70 is used to place And the positioning cable 200.

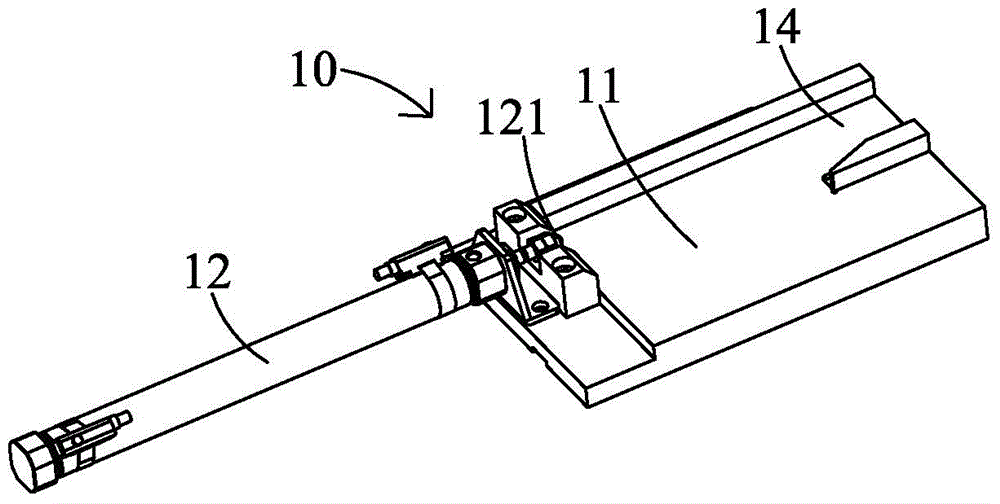

[0018] see image 3 As shown, the first feeding mechanism 10 includes a horizontal first pallet 11 and a first pen-shaped cylinder 12 fixed on the first pallet 11, and a U-shaped first guide groove 14 is provided on the surface of the first pallet 11 . The carrier 70 is placed on the first pallet 11 and positioned by the first guide groove 14, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com