Method and device for changing hole positions of drill jig

A technology for drilling holes and hole positions, which is used in boring/drilling, drilling/drilling equipment, drilling dies for workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The method for changing the drill hole position of the present invention is described in detail below:

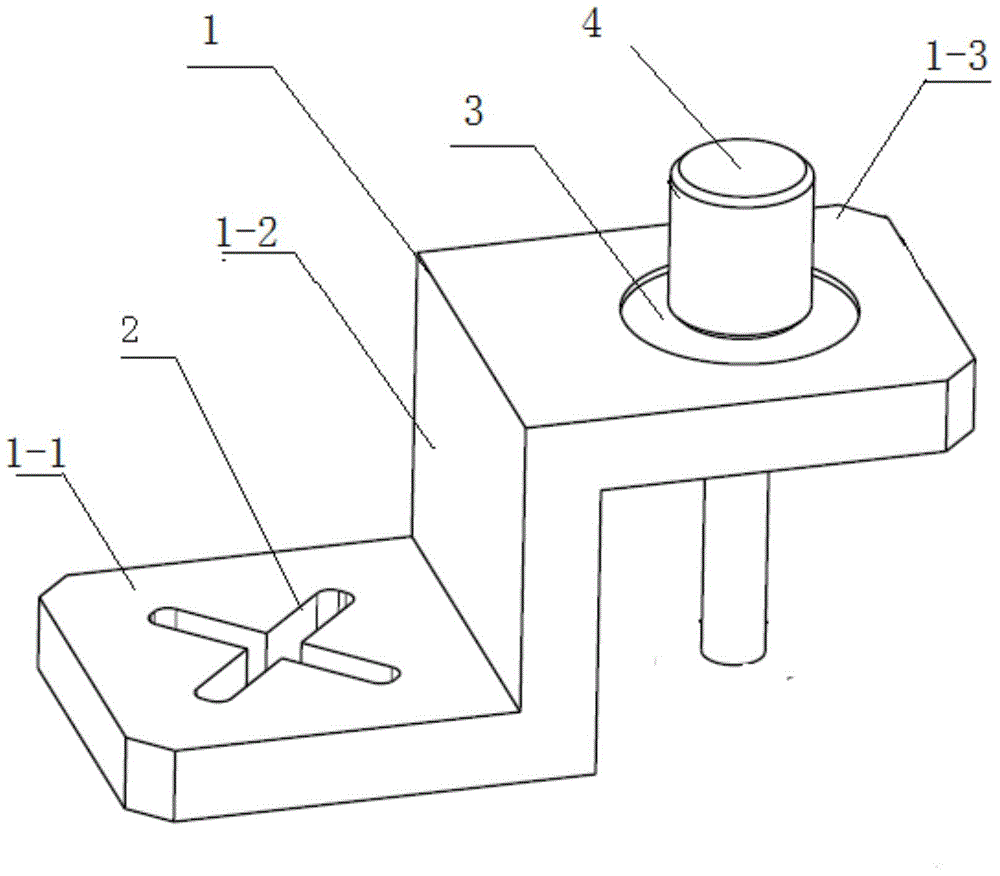

[0022] The drill template is inlaid with a drill sleeve with an outer diameter of Φ12 and an inner diameter of Φ6. figure 1 and figure 2 , Calculate the deviation value of the hole position of the drill sleeve: calculate the horizontal deviation value and the vertical deviation value of the new drill sleeve hole position and the old drill sleeve hole position, in this embodiment, the coordinates of the old hole position Φ12 hole X=100mm, Y=100mm , the coordinates of the new Φ12 hole are X=104mm, Y=103mm, the calculated lateral deviation of the new Φ12 hole and the old Φ12 hole is 4mm, and the longitudinal deviation is 3mm;

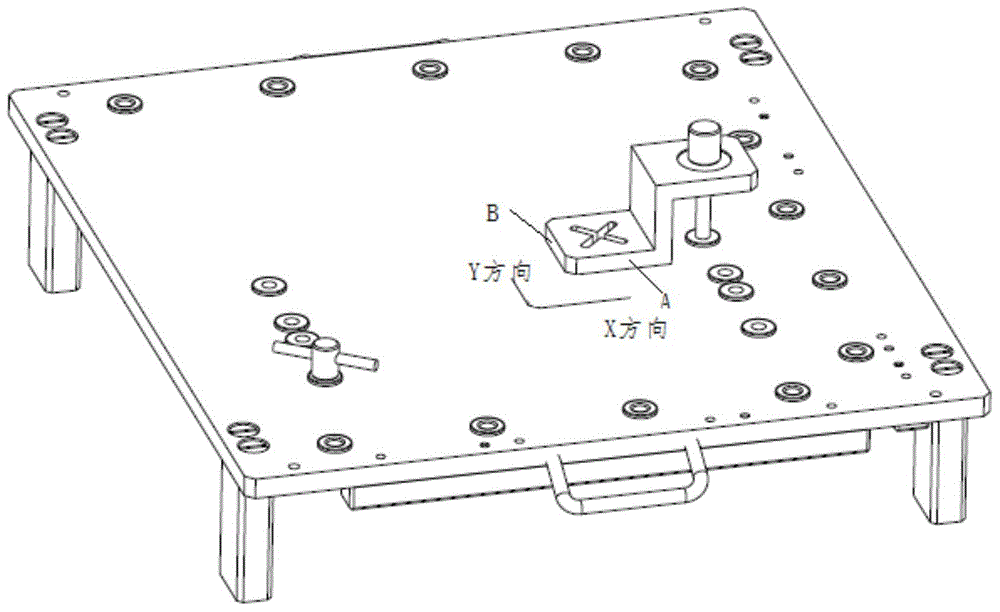

[0023] refer to figure 2 and image 3 Connect the positioning hole of the hole position transfer device with the old hole position through the positioning pin 4, and determine the horizontal positioning reference plane A and the longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com