Washing device for inner wall of water-coal-slurry pipe

A cleaning device and a technology for the inner wall of the pipe, which is applied in the field of the cleaning device for the inner wall of the coal-water slurry pipe, can solve the problems of increased running resistance of the coal-water slurry, narrowing of the section, and reduced efficiency of pipeline transportation, and achieves the effect of convenient use and flexible walking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0015] A coal-water slurry pipe inner wall cleaning device of the present invention will be described below in conjunction with the accompanying drawings.

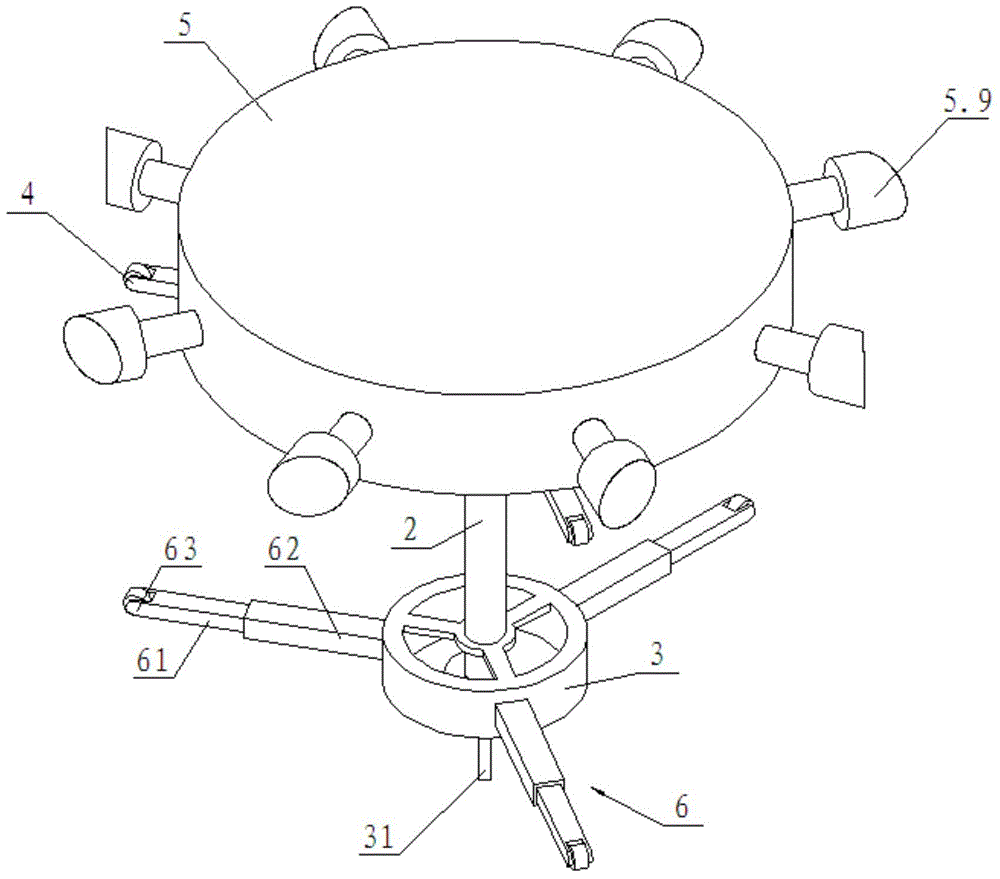

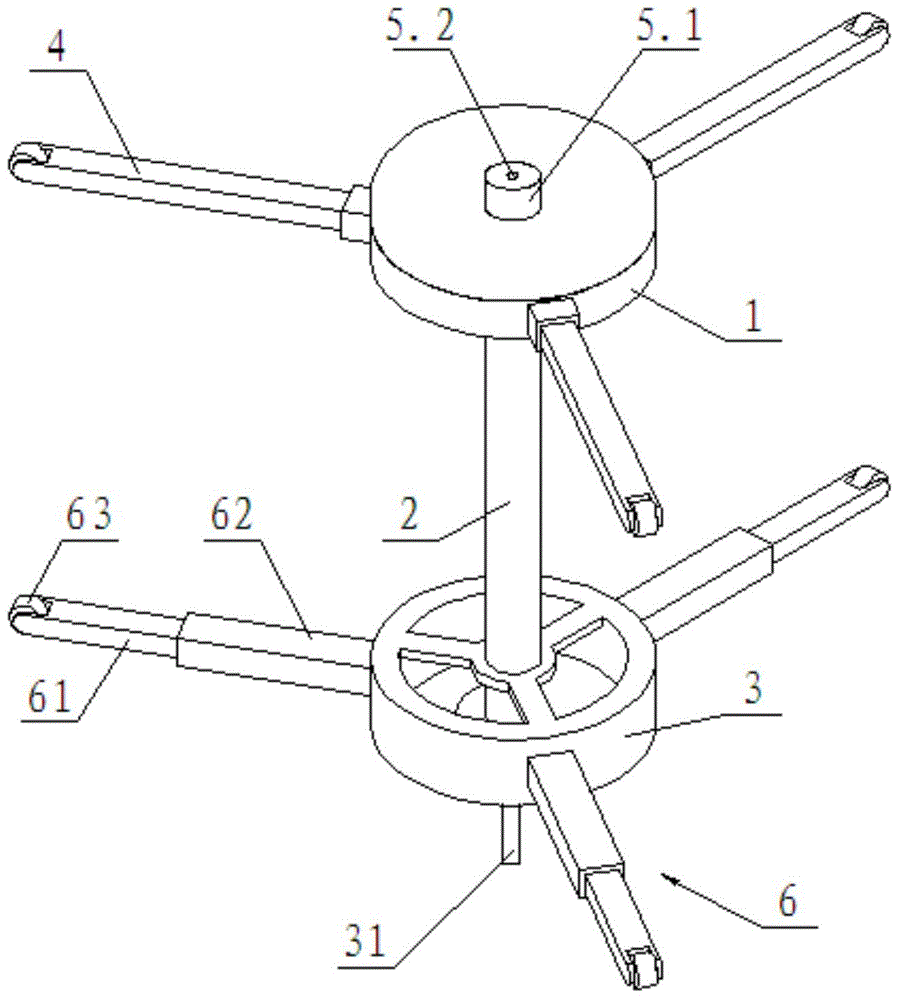

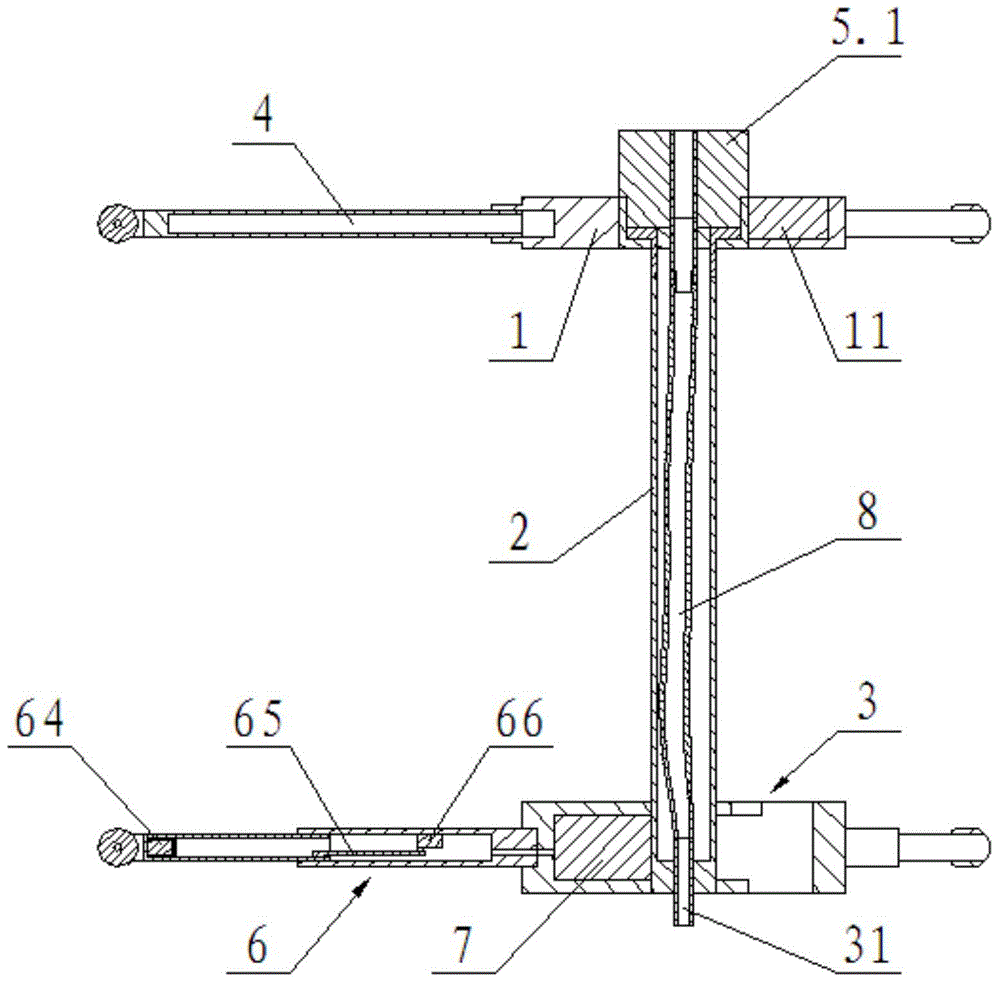

[0016] figure 1 , figure 2 , image 3 , Figure 4 As shown, a cleaning device for the inner wall of a coal-water slurry pipe includes a front stator 1, a rear stator 3, and a pillar 2; one end of the pillar 2 is fixedly connected to one end of the front stator 1, and the The other end is fixedly connected to one end of the rear stator 3; the other end of the front stator 1 is provided with a cleaning head 5, and at least three sets of first legs 4 are evenly distributed on the circumferential surface of the front stator 1, so that The inside of the front st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com