Raymond mill system with draught fan free of dust retention

A technology of Raymond mill and fan, applied in the field of Raymond mill system, can solve the problems of strong vibration, personnel and equipment safety accidents, etc., and achieve the effect of high strength, reliable use and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

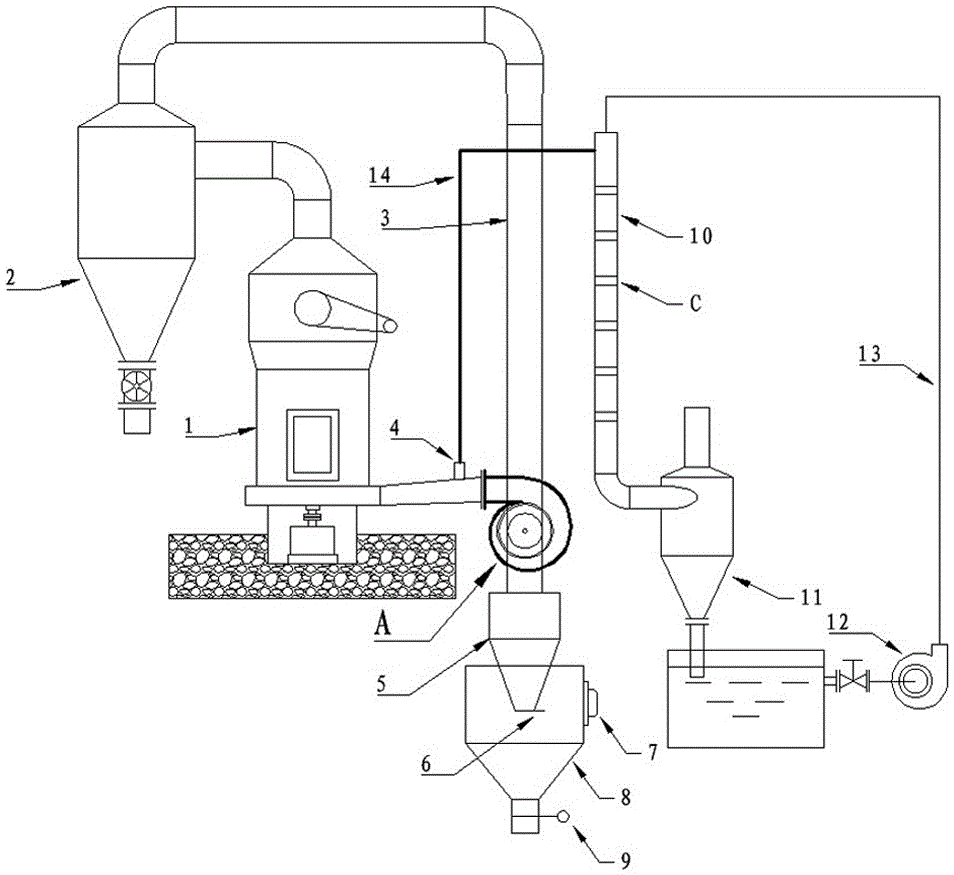

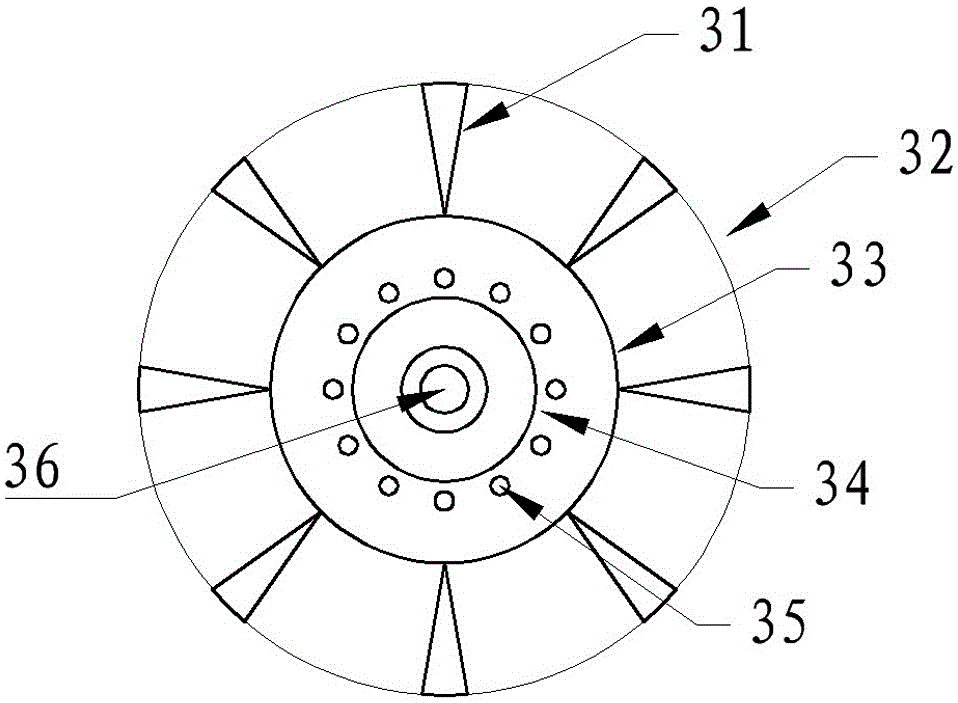

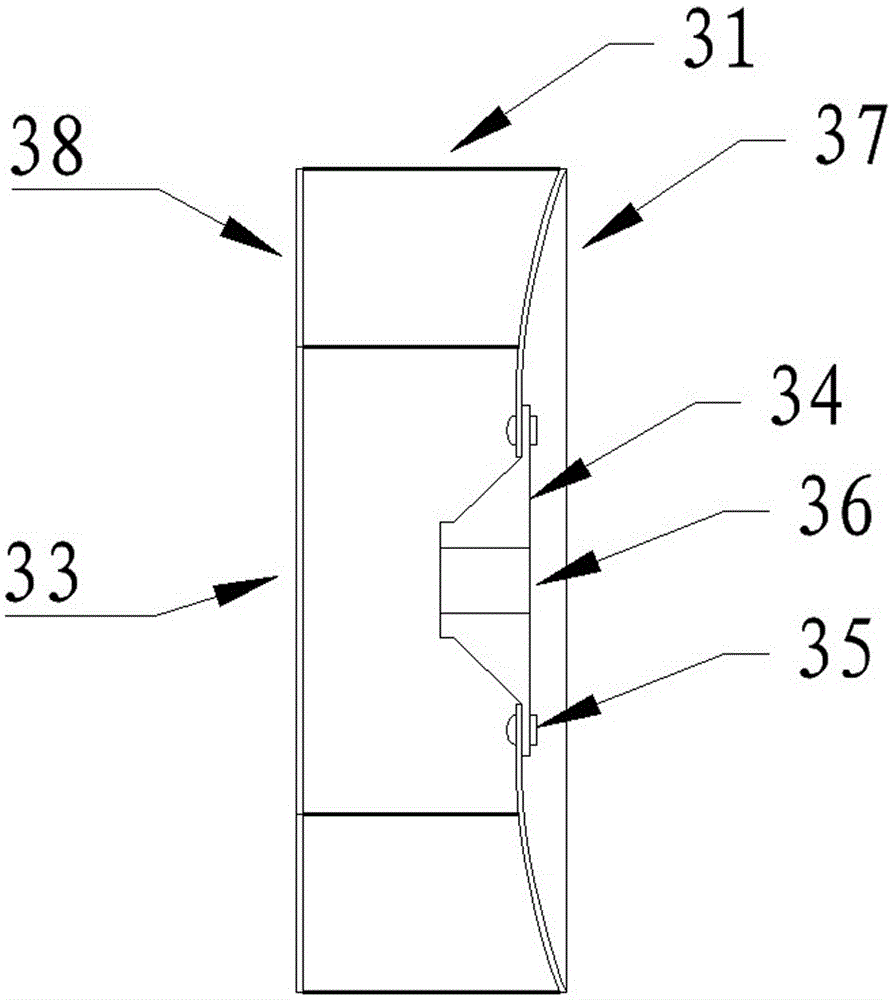

[0030] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 The Raymond mill system in which the fan does not accumulate dust includes Raymond mill 1, cyclone separator discharger 2, fan A and pressure equalizing exhaust branch pipe 14, fan A, Raymond mill 1, cyclone separator discharger 2 and The return air duct 3 constitutes an airflow circulation milling and discharging system; the pressure equalizing exhaust branch pipe 14 is connected to the upper end of the cyclone pipe 10, and a plurality of cyclones C are arranged in the cyclone pipe 10, and the lower end of the cyclone pipe 10 is tangentially connected to the cyclone separator 11, and the cyclone The upper exhaust port of the separator 11 discharges purified air, and the lower nozzle is immersed in the liquid surface of the circulating water pool to realize liquid-sealed discharge, and the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com