Delayed dropper type vapor generator and food making device based on same

A steam generator and dropper technology, which is applied to steam cooking utensils, heating devices, etc., can solve problems such as low steam heat conversion efficiency, and achieve the effects of reducing water resources waste, improving utilization rate and high heating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

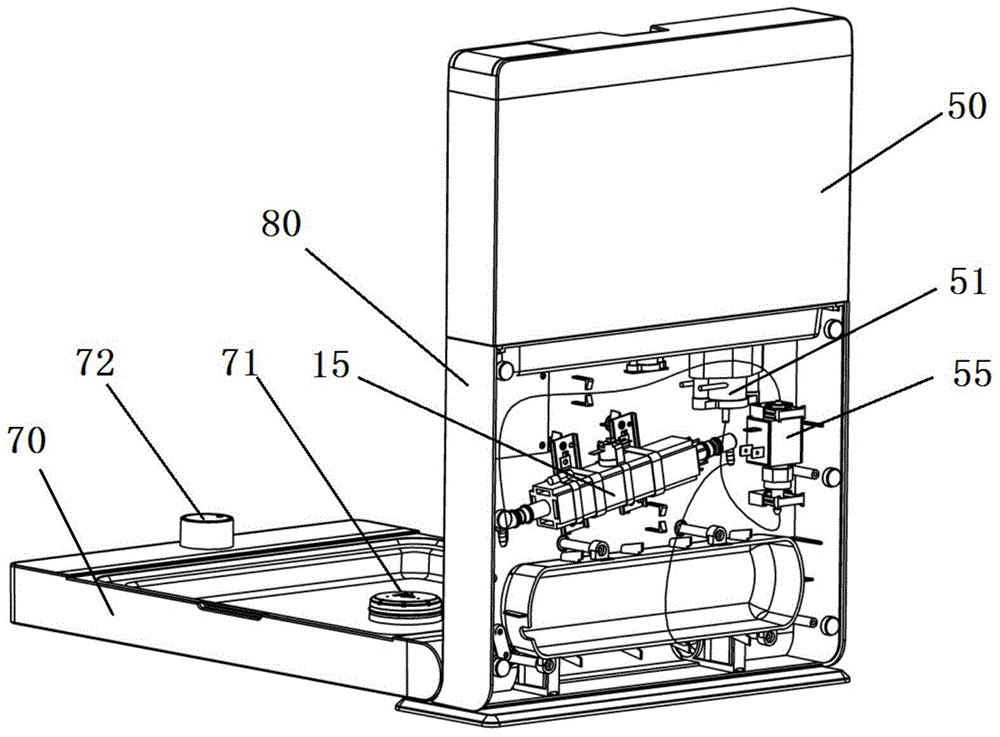

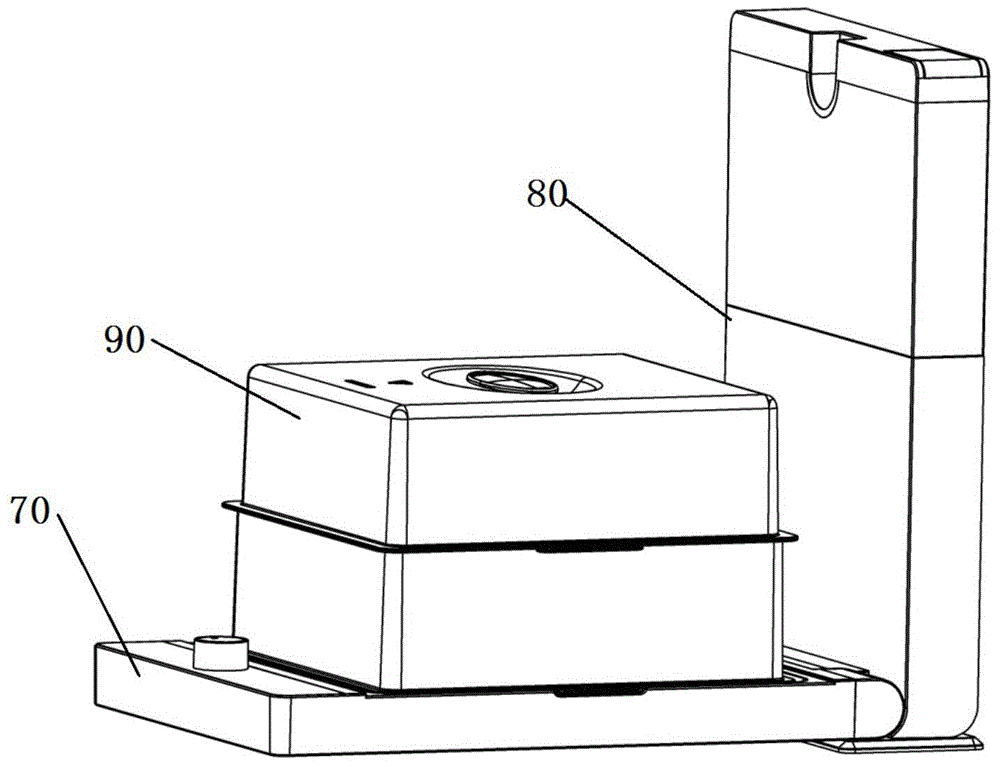

[0034] like Figure 1 to Figure 2 As shown, the food preparation equipment based on the delay dropper type steam generator provided by the embodiment of the present invention includes a base 70, a side housing 80 and a food preparation chamber 90, and a water tank 50 is installed in the side housing 80 , water pump 55, time-delay dripper type steam generator 15, the lower outlet of described water tank 50 is connected with the inlet of water pump 55, and the outlet of described water pump 55 communicates with the inlet of described time-delay dropper type steam generator 15, The outlet of the delay dropper type steam generator 15 communicates with the steam outlet 72 at the center of the base 70, and the food preparation chamber 90 is installed on the base 70 in a sealed manner so that the steam outlet 72 is filled with the food In the preparation chamber 90.

[0035] Further, the delay dropper steam generator is arranged obliquely, so that the inlet of the delay dropper stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com