Three-stage extrusion fresh wet bean vermicelli production line

A production line, fresh and wet technology, applied in the field of fresh and wet vermicelli production line, can solve the problems of high labor intensity, low efficiency, difficult to control product quality, etc., and achieve the effect of reasonable configuration and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

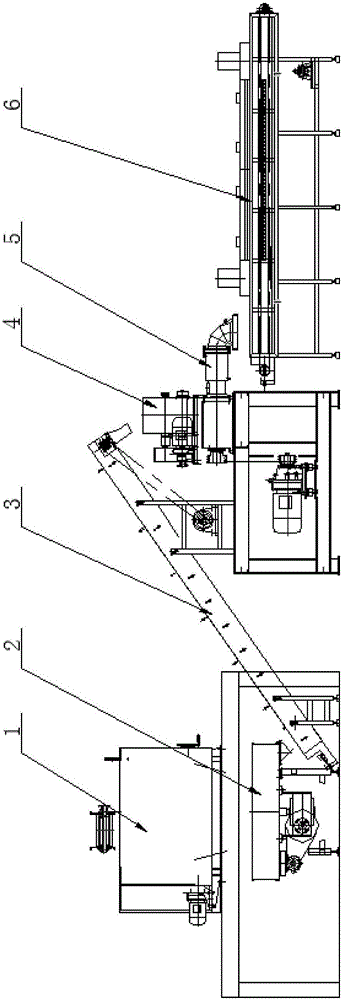

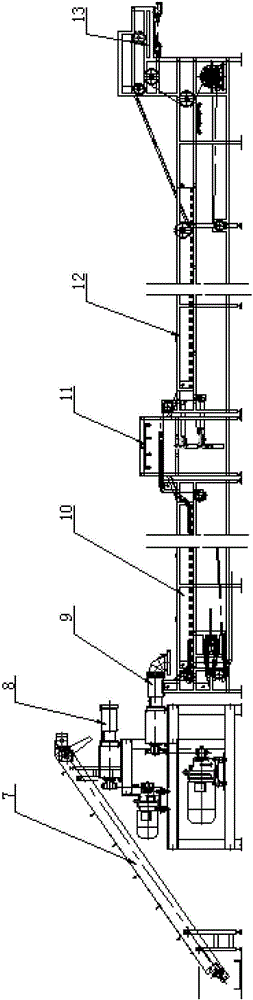

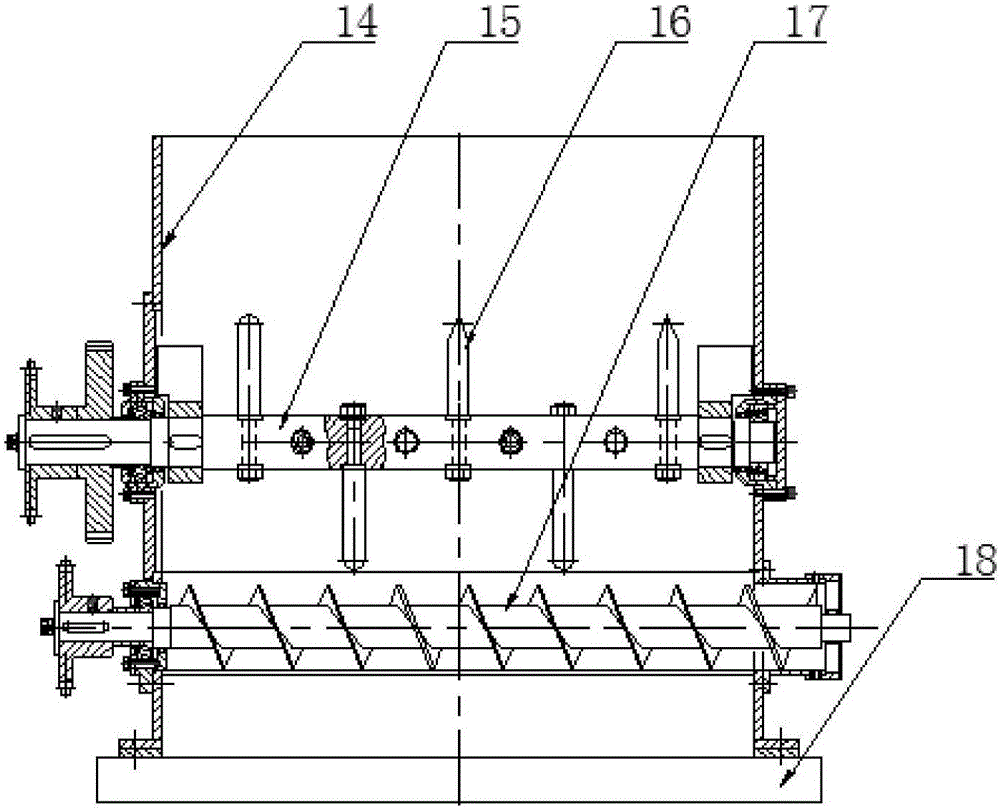

[0035] A three-stage extruded fresh and wet vermicelli production line, which is composed of a noodle maker 1, a noodle maker 2, a first elevator 3, a noodle feeder 4, a first-stage extruder 5, and a continuous steamer 6 connected in sequence , The second hoist 7, the second-level extruder 8, the third-level extruder 9, the powder cooker 10, the sprayer 11, the cooling machine 12 and the cutting machine 13.

[0036] Dough making machine, noodle making machine and elevator are all commercially available devices, and the structure is no longer described in detail. The adoption of the first-level extruder, the second-level extruder and the third-level extruder replaces the dies with different openings on the basis of the existing extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com