Worm driving rotating mechanism for threshing cylinder concave board assembly for thresher

A technology of threshing drum and rotating mechanism is applied in threshing equipment, agricultural machinery and implements, applications, etc., which can solve the problem that the concave plate assembly of the threshing drum cannot meet the requirements of production operations, and achieve good quality, reliable use and good threshing operation. The effect of technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

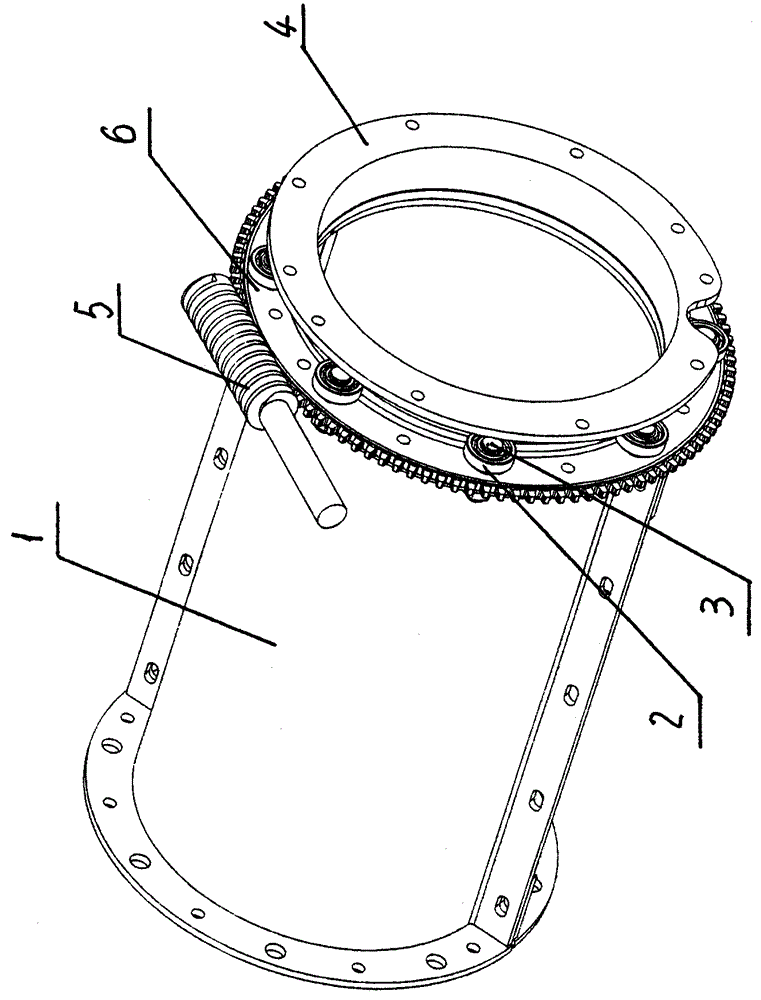

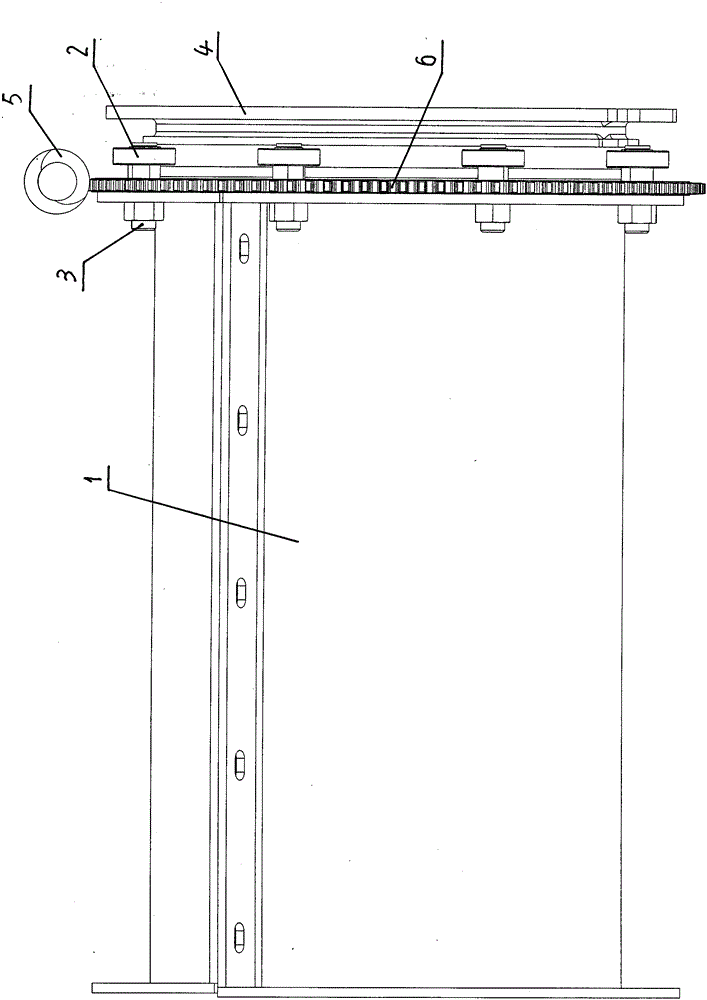

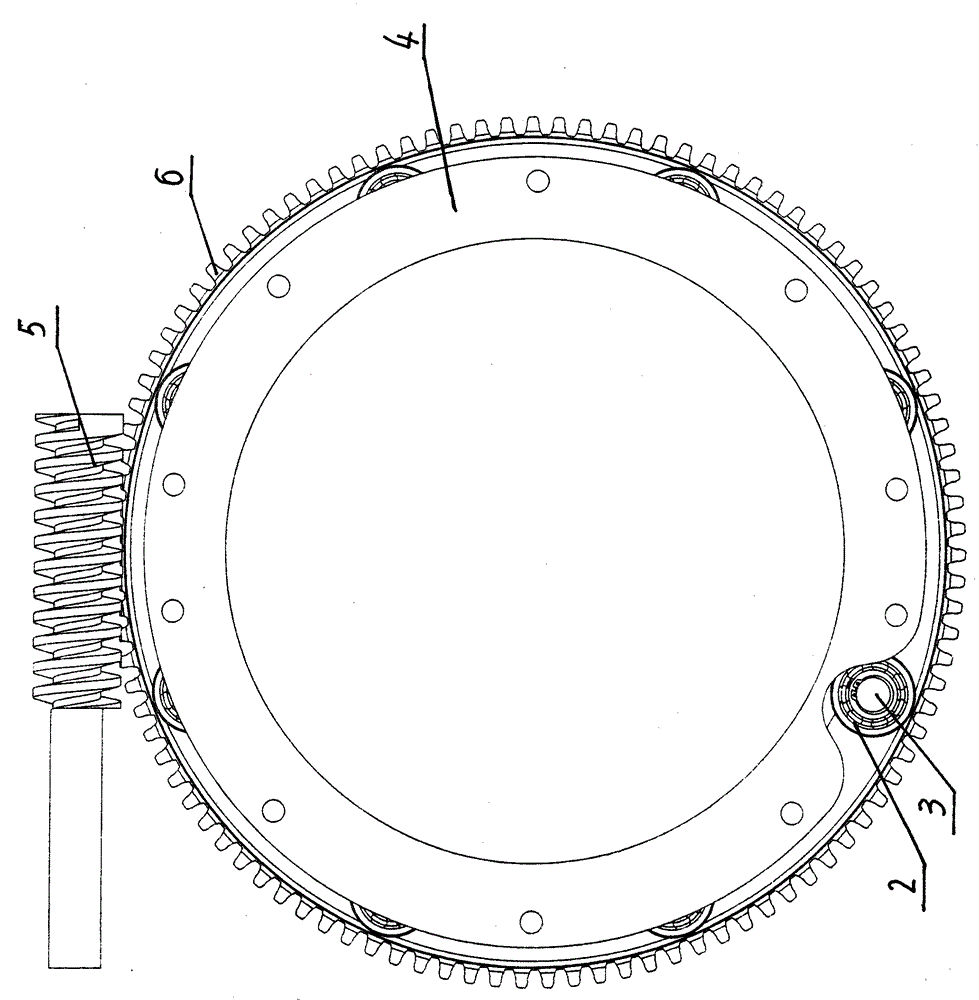

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A threshing cylinder concave plate assembly worm drive rotation mechanism for a threshing machine includes a threshing cylinder concave plate assembly 1, a worm gear ring gear 6 is fixedly installed on the end of the threshing cylinder concave plate assembly 1, and a worm gear ring gear 6 is fixed on the end of the threshing cylinder concave plate assembly 1 On the ring 6, a plurality of pin shafts 3 are evenly distributed along the circumferential direction, and rolling bearings 2 are respectively installed on the same side ends of the plurality of pin shafts 3, and at the side of the worm gear ring gear 6, it is connected with the worm gear The ring gear 6 is positioned radially, circumferentially and axially, and is fixedly arranged with the coaxial center of the rolling support ring seat 4. The rolling bearing 2 is located in the annular rolling slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com