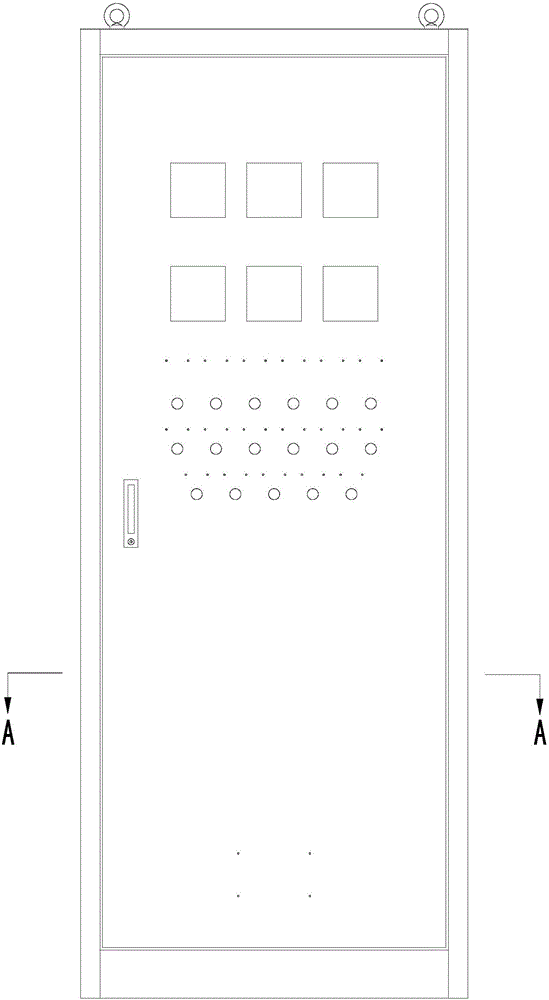

Electrical control cabinet with double panels for protection

A technology for electrical control cabinets and panels, applied in electrical equipment enclosures/cabinets/drawers, electrical components, chassis/boxes/drawer parts, etc., can solve misoperation, mechanical equipment failure, panel door splashing water And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation method, Structure, characteristic and effect thereof are as follows in detail.

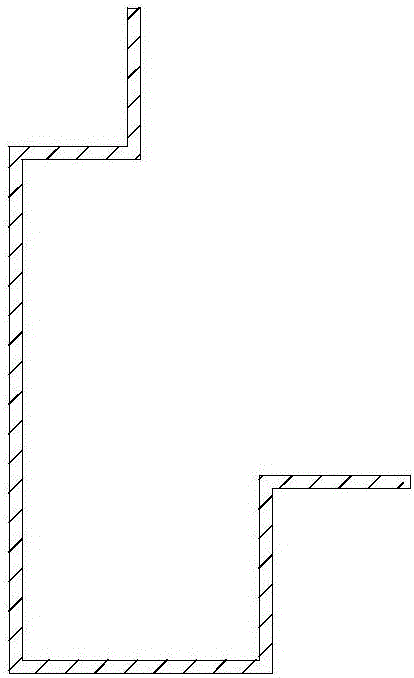

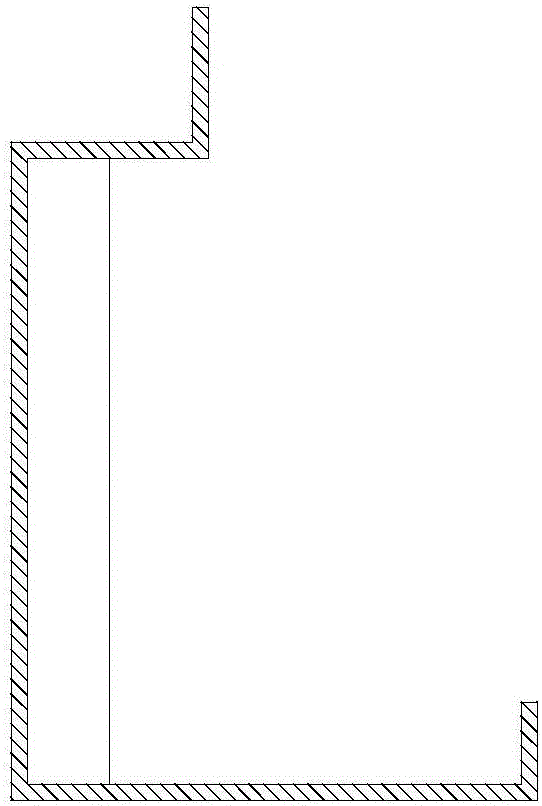

[0037] see Figure 6 , Figure 7 , Figure 8 and Figure 11 , an electrical control cabinet protected by double-layer panels in the present invention is welded to each other by two front columns 1, two front cross braces 2, two rear columns 4, two rear cross braces 6, and four side braces 5. And constitute the frame of control cabinet, side plate 7, top plate 10 are fixedly connected with frame by screw respectively, and inner panel door 8, outer panel door 3 and rear door 9 are connected together with frame by hinge respectively.

[0038] Specifically, see Figure 9 , the front column 1 of the control cabinet of the present invention is the front column of the existing cabinet frame (such as figure 2 (shown) extends inward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com