A fully automatic glue-dropping production line for decorative painting and production method thereof

A decorative painting, fully automatic technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of many shutdowns and affect work efficiency, and achieves the goal of reducing the number of shutdowns, improving work efficiency, and reducing replacement frequency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

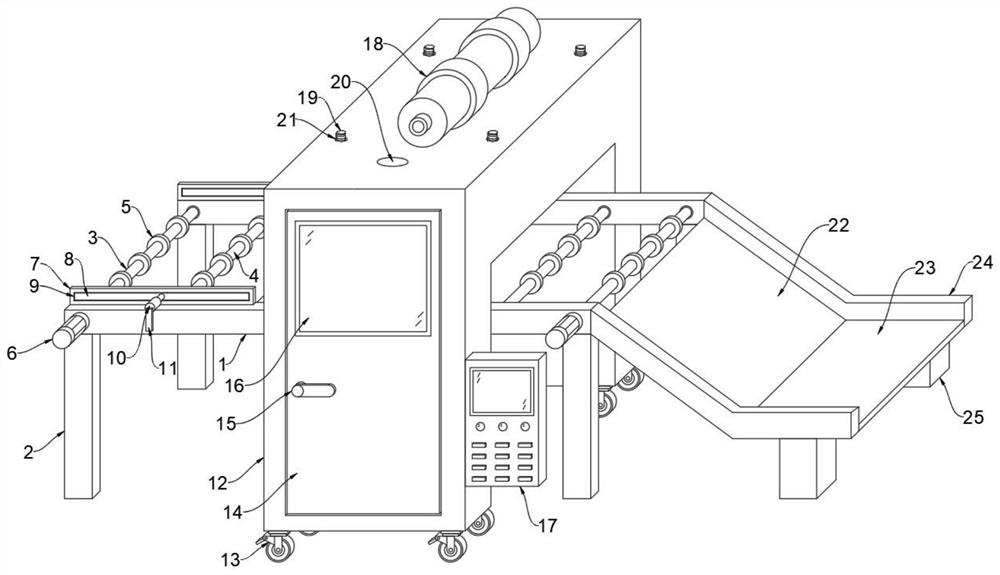

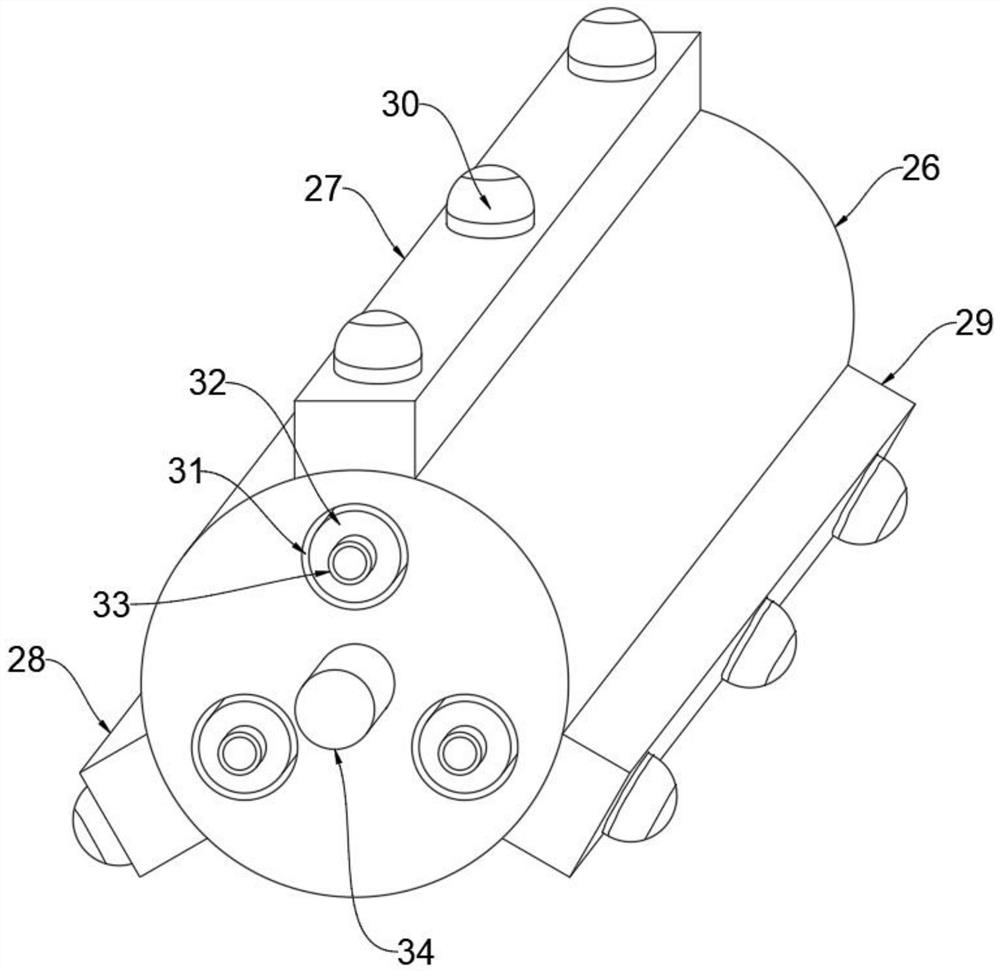

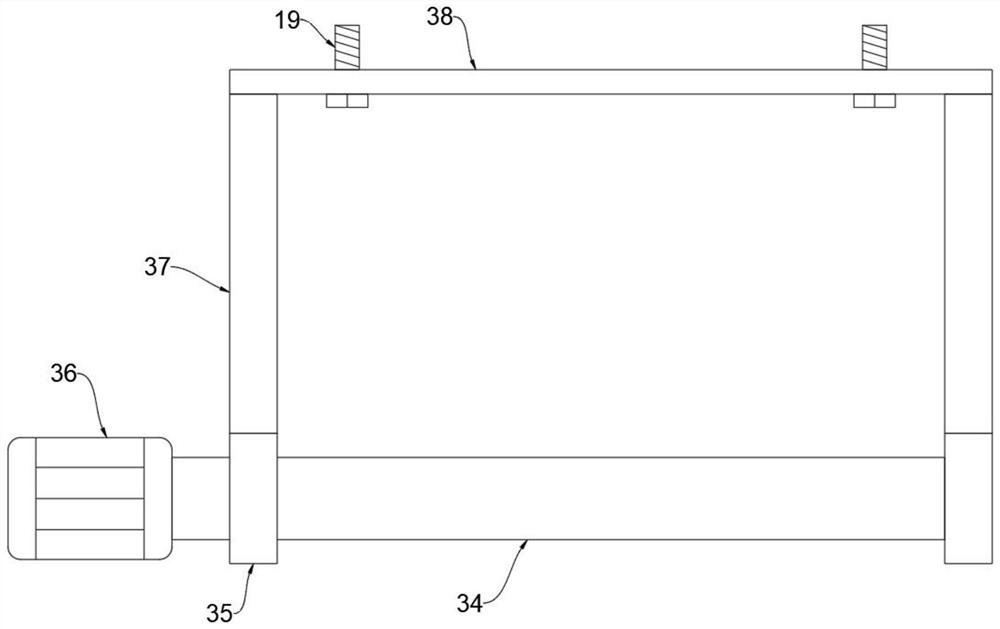

[0031] see Figure 1-5, a kind of embodiment that the present invention provides: a kind of decorative painting production is used full-automatic drip glue production line, comprises transport frame 1, and one side of transport frame 1 is provided with driving shaft 3, and one side of driving shaft 3 is provided with driven shaft 4. The exterior of the transport frame 1 is provided with a dripping rack 12, the front end of the dripping rack 12 is provided with an inspection door assembly 14, the upper end of the dripping rack 12 is provided with a booster pump mechanism 18, and the inside of the dripping rack 12 is provided with a dripping Glue rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com