Novel insulation plate

An insulating board and a new type of technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of poor insulation performance of the insulating board, poor anti-vibration buffer effect, poor safety performance, etc., and achieve good insulation effect. , Good fire resistance, anti-static effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

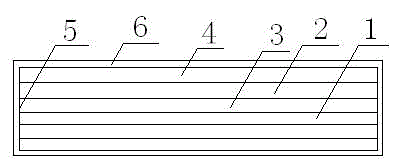

[0010] Such as figure 1 It is a schematic diagram of the structure of the present invention, a new type of insulating board, including a main board 1, glass fiber cloth 2, foam board 3, antistatic layer 4, board body 5 and vinyl resin 6, and the surface and bottom of the main board 1 are equipped with glass fiber Cloth 2, a foam board 3 is arranged between the main board 1 and the glass fiber cloth 2, an antistatic layer 4 is provided on the glass fiber cloth 2 on the surface of the main board 1, and a layer of vinyl resin 6 is covered on the outside of the board body 5.

[0011] When in use, glass fiber cloth 2 is provided on the surface and bottom of main board 1 to enhance its strength. Foam board 3 is arranged between main board 1 and glass fiber cloth 2, and the cushioning effect is good. The antistatic layer 4 can prevent the generation of static electricity, and the outside of the plate body 5 is covered with a layer of vinyl resin 6, which has good moisture-proof and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com