Method for studying material mechanics behaviors of concrete crack process zone

A technology of fracture process and material mechanics, which is applied in the direction of applying stable tension/pressure to test the strength of materials, which can solve the problems of lack of special equipment for digital detection and analysis and limited function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be described in detail below in conjunction with the accompanying drawings.

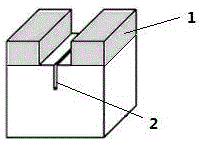

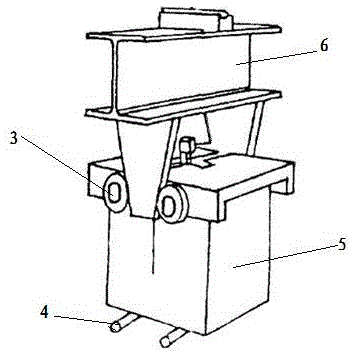

[0080] figure 1 It is a schematic diagram of a concrete test piece and a bonded steel block of the present invention; figure 2 It is a schematic diagram of the installation of the concrete test piece and the wedge-shaped loading frame of the present invention;

[0081] Such as figure 1 and 2 Shown: the present embodiment is a method for studying the mechanical behavior of materials in the concrete fracture process zone, comprising the following steps:

[0082] (1) make primary concrete specimen 5; prefabricate crack 2 at the top of specimen 5, bond steel block 1; said specimen 5 is made into three groups according to test material; include four identical specimens 5 in each group, And carry out test treatment analysis to four test pieces in each group within 24 hours; This implementation makes primary concrete test piece 5 and comprises the following steps:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com