Fully-assembled quick connector

A fast and complete technology, applied in the direction of mechanical equipment, couplings, etc., can solve the problems of affecting production efficiency, large safety risks, and the locking buckle is easy to be collided and squeezed, so as to avoid the accumulation of static charges and eliminate the safety risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

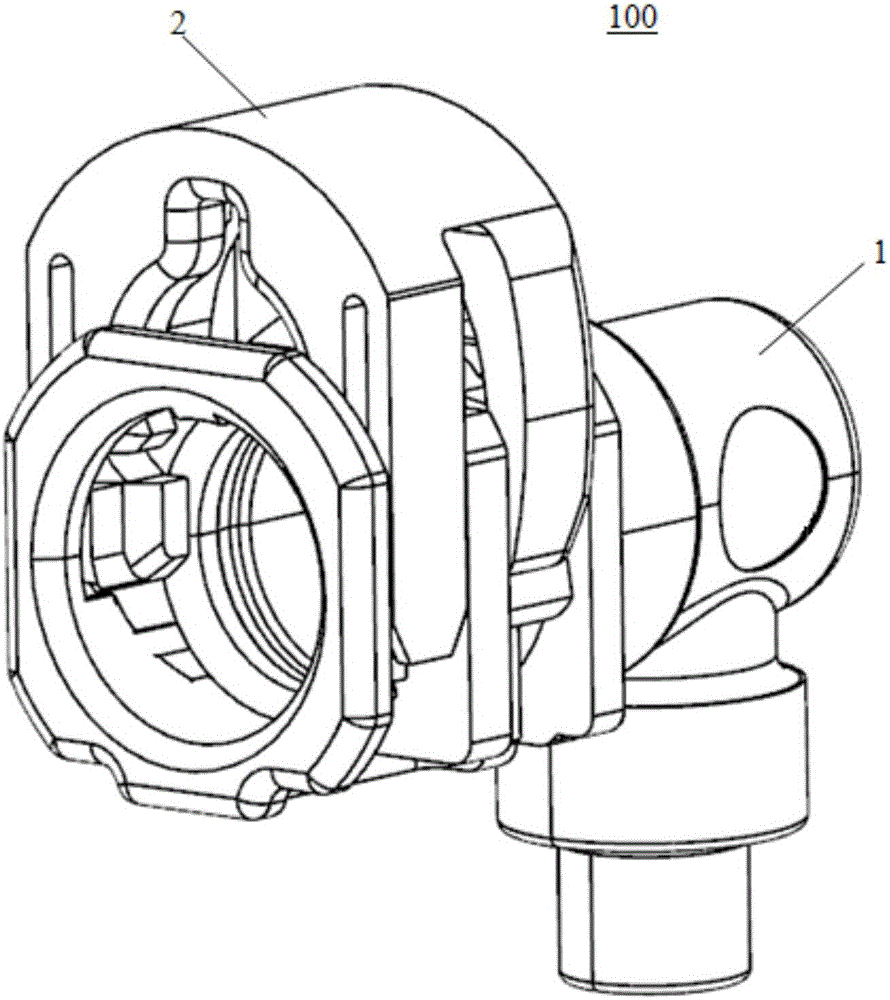

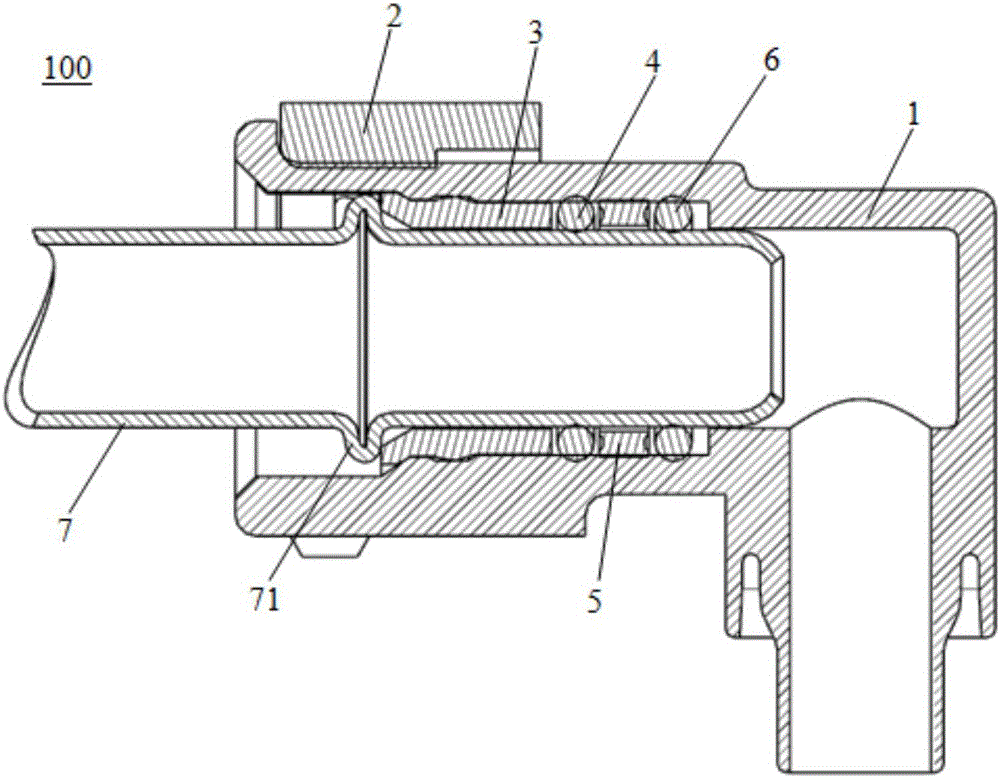

[0037] Please refer to figure 1 , figure 2 , the present embodiment is a fully assembled quick joint 100, which includes a joint body 1, a locking buckle 2 that is pressed and locked with the joint body 1, a sleeve 3 that is sequentially accommodated in the joint body 1, and a first sealing ring 4. The collar 5 and the second sealing ring 6. For the convenience of understanding, the butt pipe 7 assembled with the quick connector is shown in this specific embodiment. The butt pipe 7 is a tubular structure, and a raised portion 71 with a diameter larger than that of the pipe is provided on its surface.

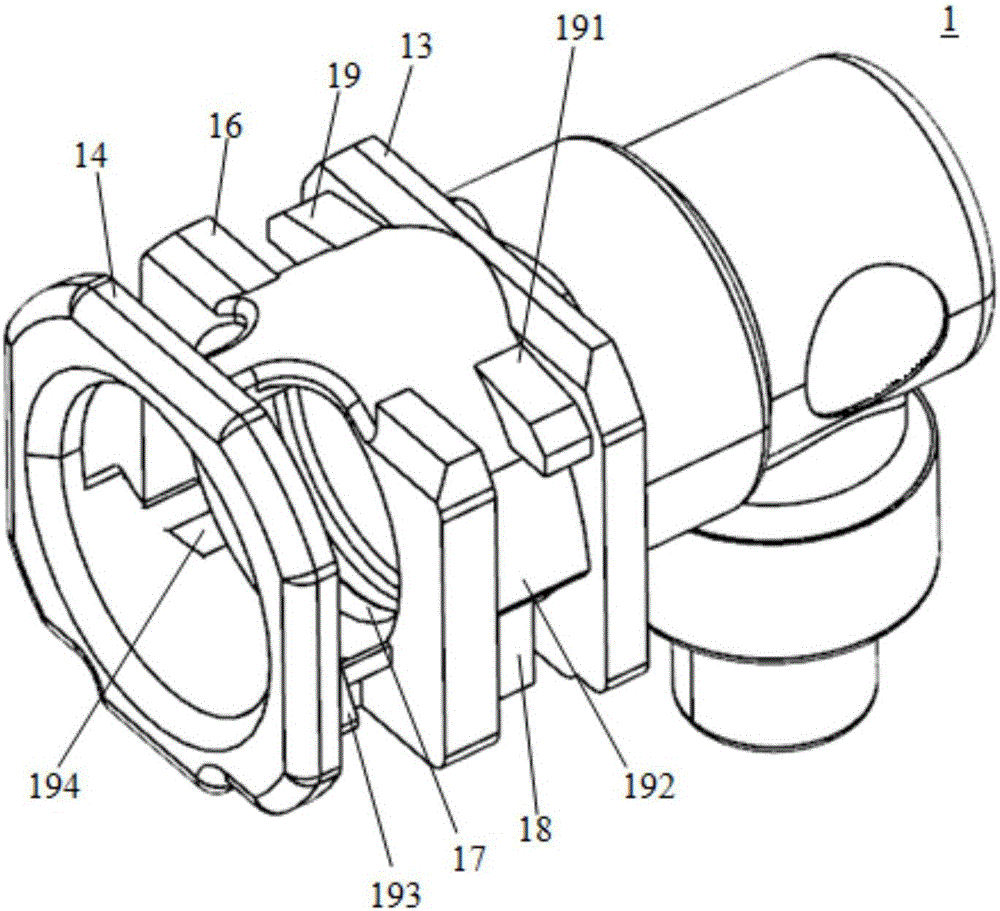

[0038] Please refer to image 3 , Figure 4 , Figure 5 The joint body 1 is an integrated structure formed by injection molding of conductive materials, which includes a first cavity 11 for accommodating the butt pipe 7, a second cavity 12 penetrating with the first cavity 11, and surrounding the joint body 1. The first baffle plate 13 on the surface, the second baffle pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com