Water pumping method of water pushing pipes and efficient liquid pump using method

A technology for liquid pumps and water pipes, which is applied to pumps, machines/engines, mechanical equipment, etc., and can solve the problems of low pressure of the pumped liquid flow, waste of liquid flow kinetic energy, and increased energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

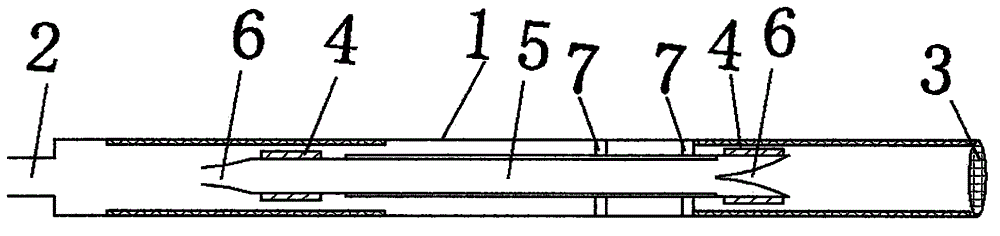

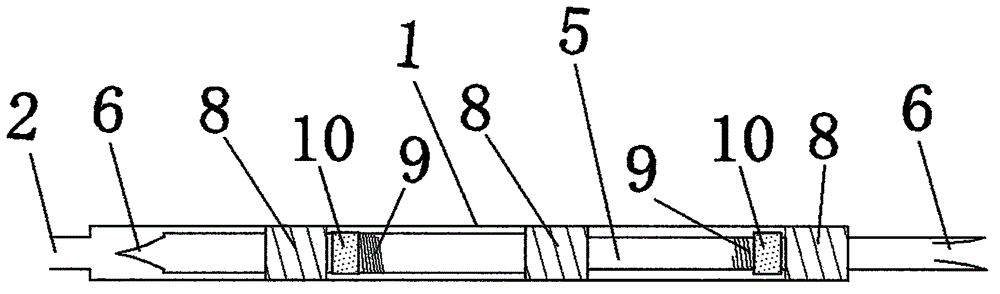

[0008] Such as image 3 , Figure 4 Put into three sets of electromagnets 8 in the pump body 1 of all, two are fixed with iron block 10, and push away the water pipe 5 of spring 9, wherein the internal diameter of one pushes away water pipe 5 is slightly larger than the outer diameter of another, two The push water pipes 5 are set together one after the other, and are attracted by electromagnetic force to reciprocate in opposite directions. When the two push water pipes 5 are pushed relative to each other, as Figure 4 As shown, when the middle electromagnetic 8 is energized first to generate electromagnetic force to attract the two water push pipes 5 with iron blocks 10 at the same time, the one-way valve 6 of the forward push water pipe 5 near the water outlet 2 is opened, and the one-way valve of the rear push water pipe 5 is opened. 6 is closed, the water is pushed out of the water outlet 2 by the water pipe 5, and then the contact breaks the circuit, such as image 3 As...

Embodiment 3

[0010] Figure 5 , Image 6 As shown, the power machine using the common shaft output power 13 uses the crankshaft 11 to cooperate with the connecting rod 12 or other methods to drive the two water pushing pipes 5 to reciprocate in opposite directions respectively. The upper end of the pump body 1 is the water outlet 2 , the middle of the water sealing ring 7 in the pump body 1 is two water pushing pipes 5, and the water pushing pipes 5 have at least one one-way valve 6 respectively, such as Figure 5 , when the crankshaft 11 rotates and the connecting rod 12 drives the two water push pipes 5 to push relative to each other, the one-way valve 6 of the forward push water pipe 5 near the water outlet 2 is opened, and the one-way valve 6 of the rear push water pipe 5 is closed, and the water is pushed back by the water pipe 5 to push out the water outlet 2, when the crankshaft 11 continues to rotate, the connecting rod 12 drives the two water push pipes 5 to push in the opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com