Double-concentric controllable-speed cutter using abrasive jets

An abrasive jet cutting and eccentric cutting technology, applied in wellbore/well components, earth-moving drilling and other directions, can solve the problems of difficult processing, complex structure, driving failure, etc., and achieve the effect of improving the efficiency of jet cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

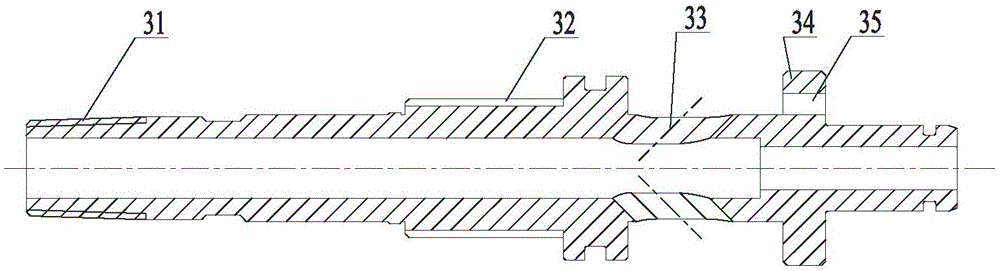

[0021] Depend on figure 1 combine figure 2 Shown: a double eccentric controllable speed abrasive jet cutter, including eccentric cutting nozzle 1, four eccentric nozzles 2, main shaft 3, outer shell 4, thrust bearing 5, friction speed limiting ring 8 and pressure shell 9; continue to combine image 3 and Figure 4 As shown: the main spindle 3 is a hollow shaft, the left end of which is provided with a tapered pipe thread 31 for connecting the eccentric cutting nozzle 1, the middle part is provided with a keyway and a thrust bearing 5 is fixed, and a sealing protection is provided on the outside Outer shell 4, its right end is provided with coaxial disc structure 34 and is covered with sealing protection pressure housing 9, also has the through hole 33 that communicates with its central hole on the main spindle on the left side of disc structure 34, disc The structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com