Variable-force viscous damper

A viscous damper, damping technology, applied in bridge parts, building components, bridges, etc., can solve the problems of reducing the protection effect of buildings, reducing, and failing to achieve, and achieve the effect of protecting the safety of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

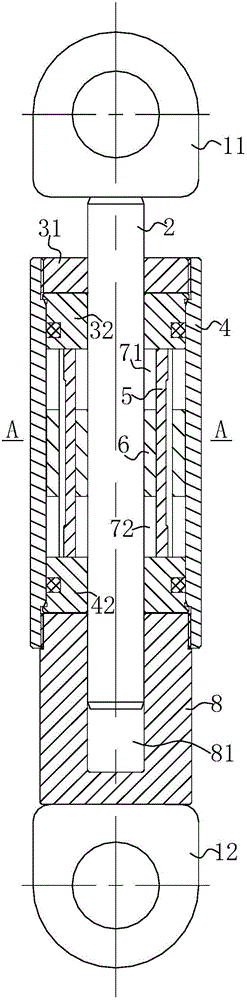

[0041] refer to figure 1 , a variable force viscous damper, including a master cylinder 4; the first sealing device and the second sealing device installed at the two ends of the master cylinder 4 respectively, the first sealing device and the second sealing device seal the inside of the master cylinder 4 The cavity forms a sealed cavity; a piston 6 that is arranged in the master cylinder 4 and can move axially, and the piston 6 divides the above-mentioned sealed cavity into a first sealed cavity 71 and a second sealed cavity 72; through the first sealing device, the piston 6 in turn And the piston rod 2 of the second sealing device, the piston rod 2 is fixedly connected with the piston 6; the damping medium filled in the first sealing cavity and the second sealing cavity.

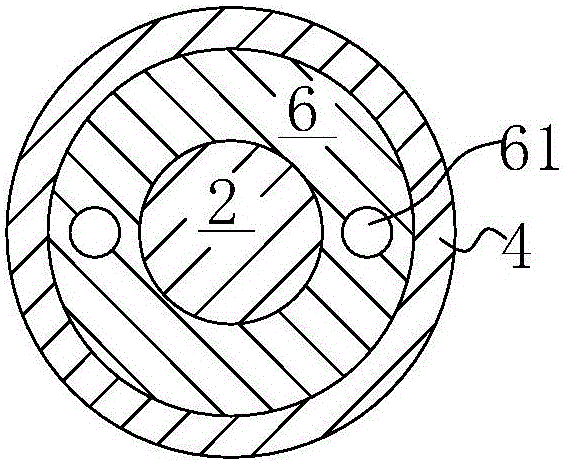

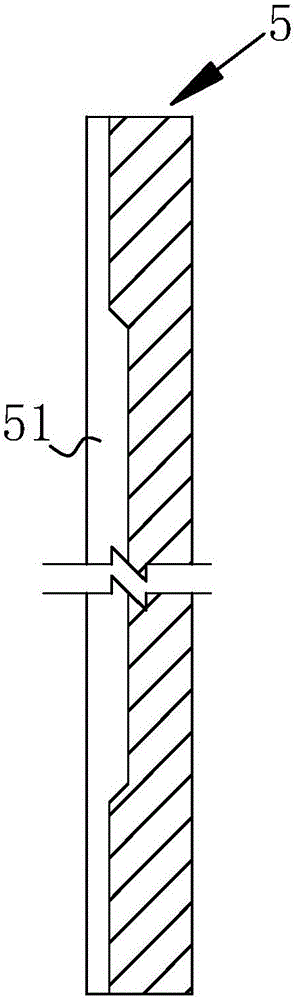

[0042] refer to figure 2 At least two damping through-holes 61 are uniformly arranged on the piston 2, and the central axis of the damping through-hole 61 is parallel to the central axis of the piston 2;...

Embodiment 2

[0055] In this embodiment, H12=0.5H11, H13=0.5H11;

[0056] S2=0.10S1;

[0057] L2=0.2L1, L3=0.2L1,

[0058] The meanings of all symbols in this embodiment are the same as in Embodiment 1.

[0059] The number of damping through holes is 5; the number of long slots on each damping major axis is 12.

Embodiment 3

[0061] In this embodiment, H12=0.3H11, H13=0.5H11;

[0062] S2=0.07S1;

[0063] L2=0.1L1, L3=0.2L1,

[0064] The meanings of all symbols in this embodiment are the same as in Embodiment 1.

[0065] The number of damping through holes is 8; the number of long slots on each damping major axis is 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com