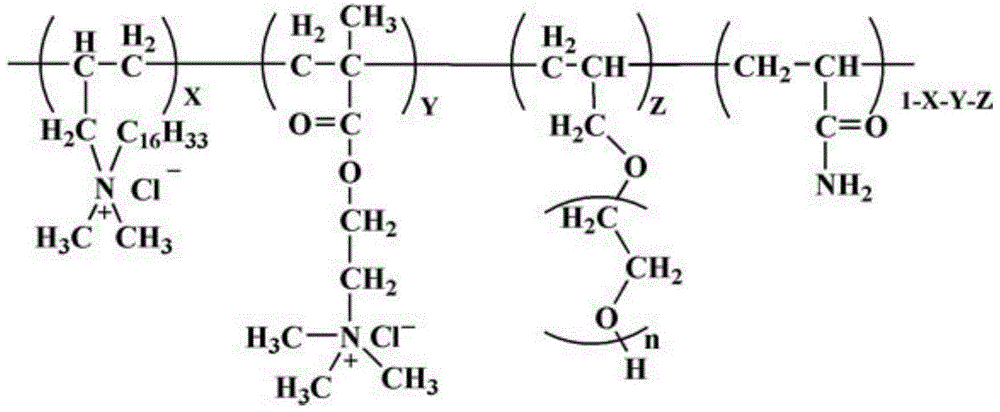

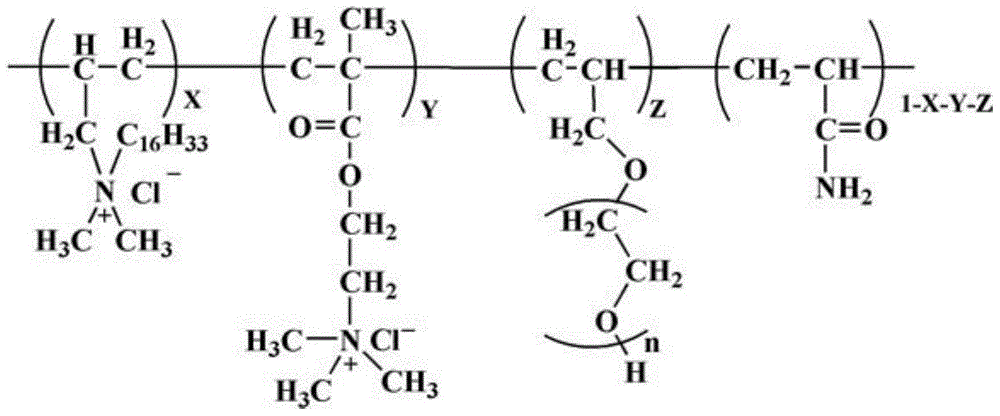

Hydrophobically associated type cation acid solution retardant and preparation method thereof

A cationic acid, hydrophobic association technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as limited application scope, and achieve good compatibility, high yield, and good retardation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 A kind of preparation method of hydrophobic association type cationic acid liquid retarder

[0016] Add 3.52g of allyl polyoxyethylene ether APEG-1000 into a 150mL flask, add 65.73 of deionized water, then add 5.00g of acrylamide AM, after the dissolution is complete, add 2.92g of methacryloxy Ethyltrimethylammonium chloride DMC, after dissolving completely, add 0.16g of hexadecyldimethylallyl ammonium chloride DMAAC-16 to obtain a solution with a monomer mass percentage concentration of 15%, and then add Initiator azobisisobutylamidine hydrochloride 0.024g, after dissolving completely, react at a temperature of 50°C for 6h to obtain a gel-like product, which is washed and purified with absolute ethanol for 3 times, and the product is dried in an oven at a temperature of 50°C After medium drying for 24 hours, the acid retarder was prepared.

Embodiment 2

[0017] Embodiment 2 A kind of preparation method of hydrophobic association type cationic acid liquid retarder

[0018] Add 8.80g of allyl polyoxyethylene ether APEG-1000 into a 200mL flask, add 115.32g of deionized water, then add 5.00g of acrylamide AM, after the dissolution is complete, add 6.39g of methacrylamide Oxyethyl trimethyl ammonium chloride DMC, after dissolving completely, add the hexadecyl dimethyl allyl ammonium chloride DMAAC-16 of 0.16g, obtain the solution that monomer mass percent concentration is 15%, then Add 0.061 g of initiator azobisisobutylamidine hydrochloride, after the dissolution is complete, react at a temperature of 50°C for 6 hours to obtain a gel-like product, which is washed and purified with absolute ethanol for 3 times, and the product is heated at a temperature of 50°C After drying in an oven for 24 hours, the acid retarder is prepared.

Embodiment 3

[0019] Embodiment 3 A kind of preparation method of hydrophobic association type cationic acid liquid retarder

[0020] Add 1.76g of allyl polyoxyethylene ether APEG-1000 into a 100mL flask, add 58.14g of deionized water, then add 5.00g of acrylamide AM, after the dissolution is complete, add 3.29g of methacrylamide Oxyethyl trimethyl ammonium chloride DMC, after dissolving completely, add the hexadecyl dimethyl allyl ammonium chloride DMAAC-16 of 0.21g, obtain the solution that monomer mass percent concentration is 15%, then Add 0.041 g of initiator azobisisobutylamidine hydrochloride, after the dissolution is complete, react at a temperature of 50°C for 6 hours to obtain a gel-like product, which is washed and purified with absolute ethanol for 3 times, and the product is heated at a temperature of 50°C After drying in an oven for 24 hours, the acid retarder is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com