Oil-field wastewater treating and recycling device

A technology for oil extraction wastewater and desalination device, which is applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of fouling, high cost, membrane calcification, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

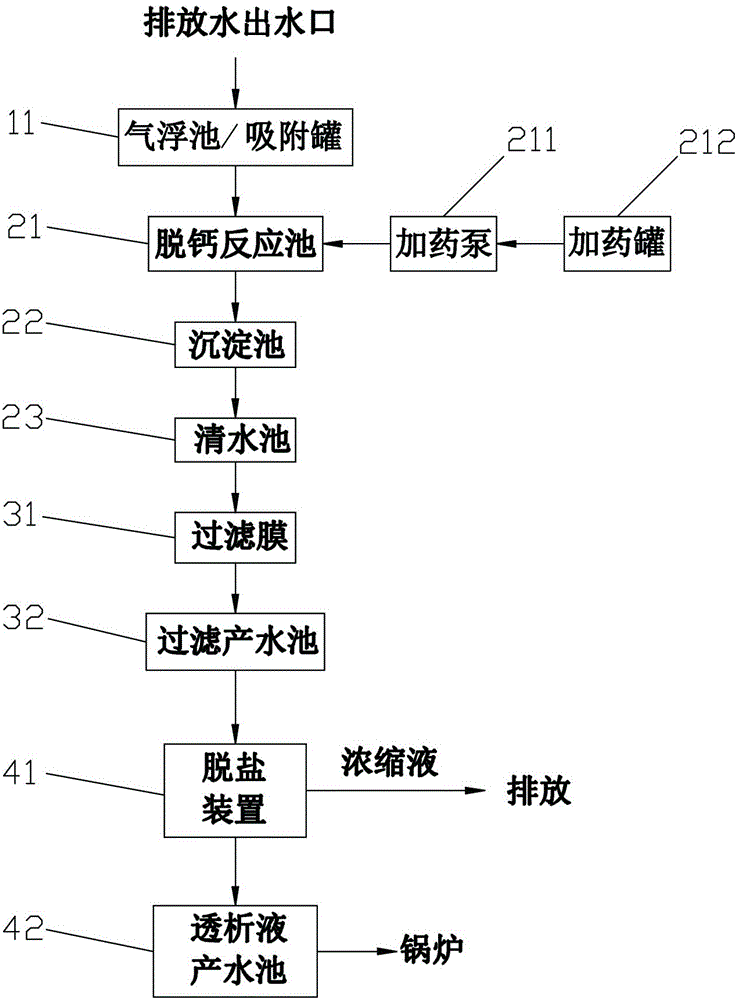

[0038] An oil extraction wastewater treatment and recycling device, refer to figure 1 , Including oil removal system, chemical decalcification system, membrane filtration system and desalination system.

[0039] The oil removal system is used to remove the oil pollution in the oil production wastewater. The oil removal system includes the air flotation tank 11 (or adsorption tank), the inlet of the air flotation tank (or adsorption tank) is connected to the oil extraction wastewater discharge water outlet, and the air flotation tank (or adsorption tank) The outlet is connected to a chemical decalcification system.

[0040] The chemical decalcification system is used to remove calcium and magnesium ions in the oil production wastewater and reduce the hardness of the water. The chemical decalcification system includes a decalcification reaction tank 21, a sedimentation tank 22 and a clear tank 23. The inlet of the decalcification reaction tank 21 is connected to an air floatation tank...

Embodiment 2

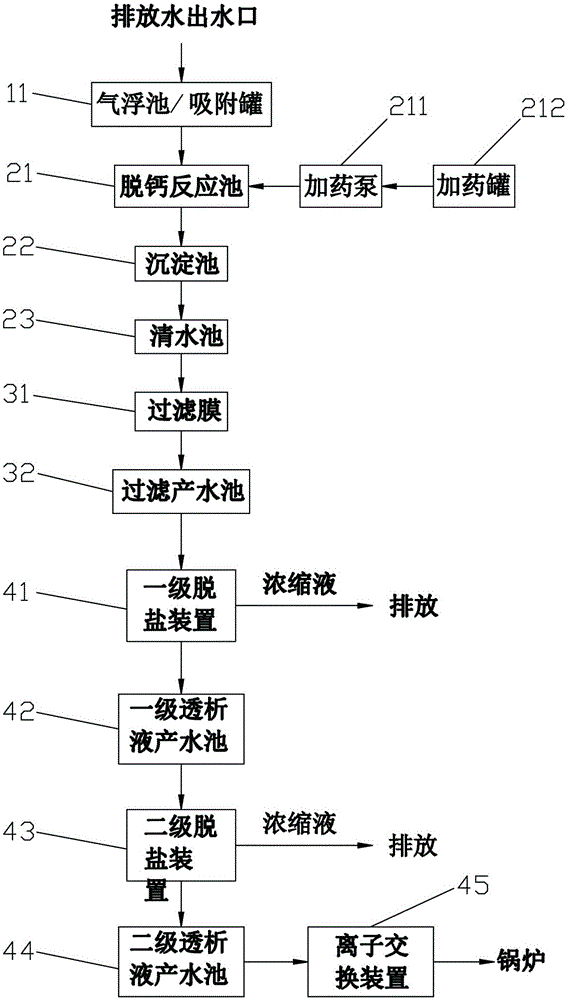

[0050] An oil extraction wastewater treatment and recycling device, refer to figure 2 , Including oil removal system, chemical decalcification system, membrane filtration system and desalination system.

[0051] The oil removal system is used to remove oil from the oil production wastewater. The oil removal system includes an air flotation tank 11 (or adsorption tank), the inlet of the air flotation tank (or adsorption tank) is connected to the oil extraction wastewater discharge water outlet, and the air flotation tank (or adsorption tank) The outlet is connected to a chemical decalcification system.

[0052] The chemical decalcification system is used to remove calcium and magnesium ions in the oil production wastewater and reduce the hardness of the water. The chemical decalcification system includes a decalcification reaction tank 21, a sedimentation tank 22 and a clear tank 23. The inlet of the decalcification reaction tank 21 is connected to an air floatation tank. 11 or the...

Embodiment 3

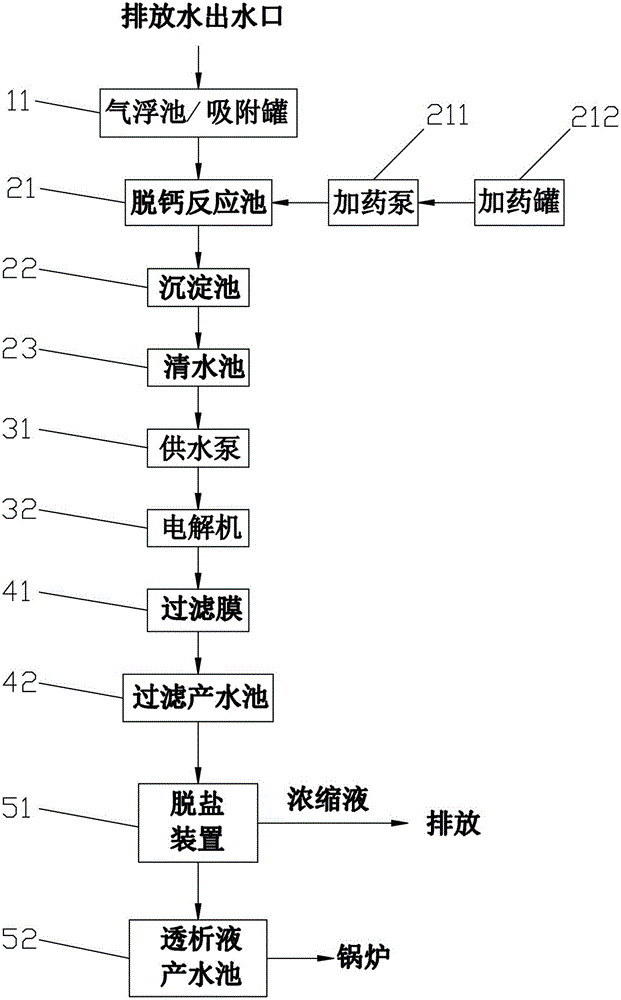

[0062] An oil extraction wastewater treatment and recycling device, refer to image 3 , Including oil removal system, chemical decalcification system, electrolysis system, membrane filtration system and desalination system.

[0063] The oil removal system is used to remove oil from the oil production wastewater. The oil removal system includes an air flotation tank 11 (or adsorption tank), the inlet of the air flotation tank (or adsorption tank) is connected to the oil extraction wastewater discharge water outlet, and the air flotation tank (or adsorption tank) The outlet is connected to a chemical decalcification system.

[0064] The chemical decalcification system is used to remove calcium and magnesium ions in the oil production wastewater and reduce the hardness of the water. The chemical decalcification system includes a decalcification reaction tank 21, a sedimentation tank 22 and a clear tank 23. The inlet of the decalcification reaction tank 21 is connected to an air floatat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com