Hydrocarbon reforming catalyst for directly reducing iron with gas group and preparation method

A technology for reforming catalysts and reducing iron, which is applied in the field of hydrocarbon reforming catalysts and their preparation, can solve problems such as the complex production process of hydrocarbon gas reforming catalysts, achieve strong activity and activity stability, increase strength, and improve dispersion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

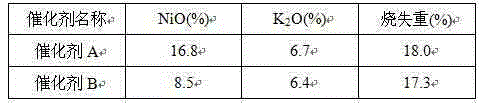

[0034] Implementation example one: preparation of catalyst A

[0035] 1) Take the prepared 1.8mol / L Mg(NO 3 ) 2 Solution 700L, 1.3mol / L Ca(NO 3 ) 2 Solution 42L, 2.5 mol / L Ni(NO 3 ) 2 Add 420L of the solution to the reactor, and start stirring to mix the solution evenly, and use 10% Na 2 CO 3 The solution neutralizes the pH value of the solution to 7.7-8.0, and continuously stirs the solution during this process. After the reaction, continue to stir for 10 minutes, stop stirring and then age for 10 minutes, filter and wash 6 times.

[0036] 2) The washed and filtered sample was dried at 120°C for 2 hours, and then calcined at 550°C for 4 hours to obtain the active material of the catalyst.

[0037] 3) Take 600g of active material, 630g of potassium aluminosilicate double salt, 430g of pure calcium aluminate cement, 33g of lanthanum oxide, and 33g of graphite, mix and ball mill for 2 hours, knead, granulate, and press to form.

[0038] 4) The pressed and molded catalys...

Embodiment 2

[0039] Implementation example two: preparation of catalyst B

[0040] 1) Take the prepared 1.8mol / L Mg(NO 3 ) 2 Solution 700L, 1.3mol / L Ca(NO 3 ) 2 Solution 42L, 2.5 mol / L Ni(NO 3 ) 2 Add 420L of the solution to the reactor, and start stirring to mix the solution evenly, and use 10% Na 2 CO 3 The solution neutralizes the pH value of the solution to 7.7-8.0, and continuously stirs the solution during this process. After the reaction, continue to stir for 10 minutes, stop stirring and then age for 10 minutes, filter and wash 6 times.

[0041] 2) The washed and filtered sample was dried at 120°C for 2 hours, and then calcined at 550°C for 4 hours to obtain the active material of the catalyst.

[0042] 3) Take 300g of active material, 630g of potassium aluminosilicate double salt, 700Kg of pure calcium aluminate cement, 33g of lanthanum oxide, and 33g of graphite, mix and ball mill for 2 hours, knead, granulate, and press to form.

[0043] 4) After curing the green ring of t...

Embodiment 3

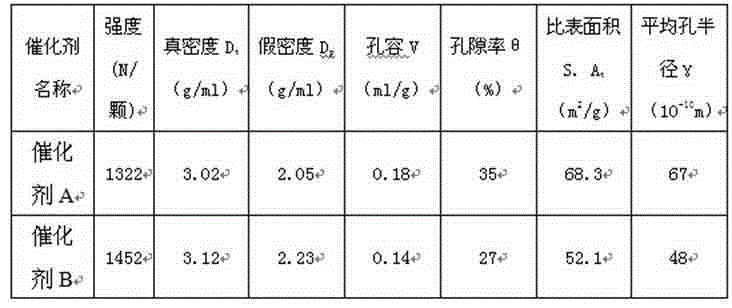

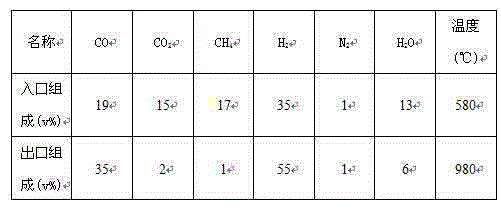

[0049] This example is to measure the activity and other comprehensive properties of the gas-based direct reduction iron hydrocarbon reforming catalysts (corresponding to catalyst models: catalyst A and catalyst B) obtained in the above-mentioned Examples 1 and 2.

[0050] Under the conditions of normal pressure, inlet 550°C and outlet 900°C, reduce for 8 hours, and reduce space velocity 2000 hours -1 . After the reduction, water and raw material dry gas are fed into the system, and the comprehensive test of activity, activity stability and carbon resistance is carried out at a pressure of 0.2MPa, an inlet of 550°C, and an outlet of 925°C. The results are shown in Table 4 below:

[0051] Table 4 Catalyst comprehensive performance test results

[0052]

[0053] It can be seen from the above table 4 that the catalyst of the present invention exhibits good activity and activity stability, and the conversion rate is very high, and the unloaded catalyst is also complete withou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com