A slurry tank agitator

A technology of agitator and pulp, which is applied in the direction of agitator accessories, chemical instruments and methods, dissolution, etc., can solve the problems of shortened service life of agitator drive internal bearings, increased maintenance costs, sloshing of agitator shafts, etc., to achieve stable agitation operation and overall Strong stability and the effect of increasing the stirring load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

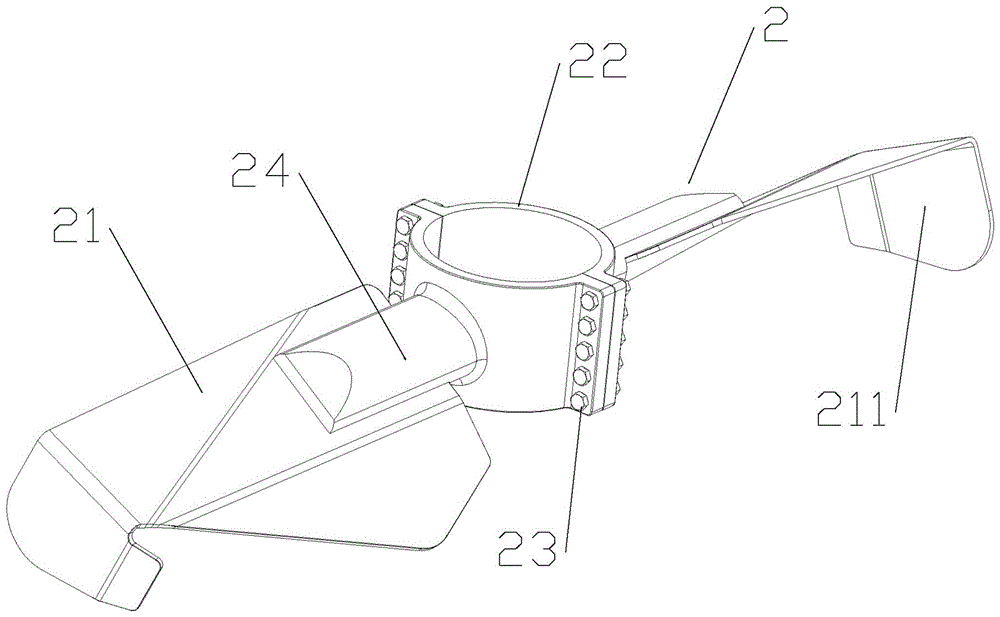

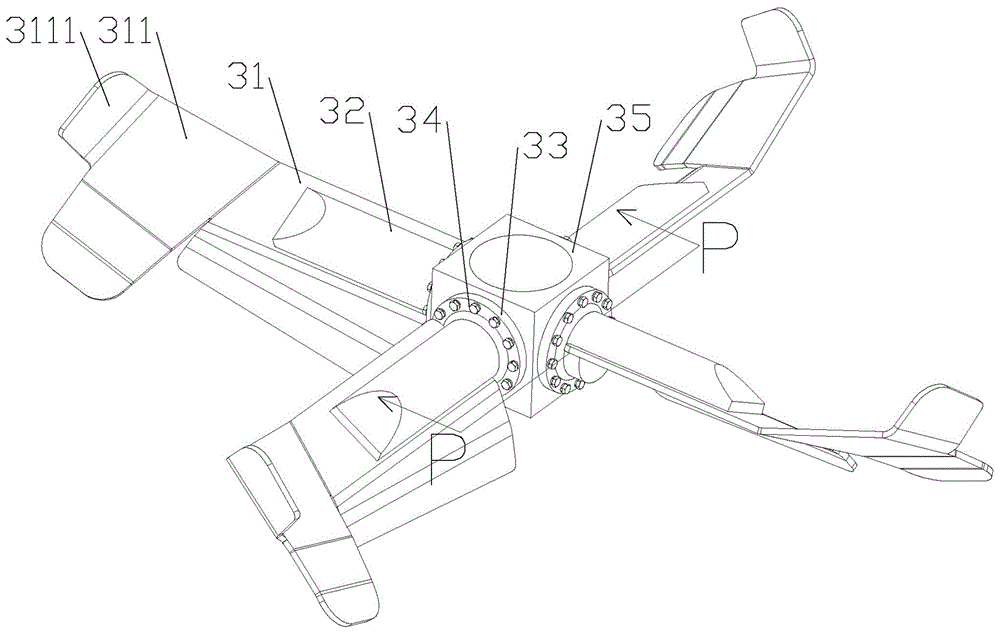

[0025] Such as Figure 1-4 Shown: a slurry tank agitator, comprising a stirring shaft 1, the top of the stirring shaft 1 is provided with a stirring shaft flange 11 and the stirring shaft flange 11 strengthens the stability of the connection with the stirring shaft 1 through the stirring shaft rib 12; The bottom end of the shaft 1 is fixed with an impeller B3, and above the impeller B3 is an impeller A2 fixed on the stirring shaft 1. The impeller A2 includes a blade A21 and a hoop-type hub 22, and two left and right halves are symmetrically distributed. Type hub 22 is tightened and fastened on the stirring shaft 1 by bolt A23, blade A21 is welded on reinforcement rib A24 and reinforcement rib A24 is welded and connected with hoop type hub 22, so that two groups of blades A21, reinforcement rib A24 and hoop type hub 22 and the corresponding bolts A23 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com