Fine particles purification device

A technology for fine particles and purification equipment, which is applied to the separation of dispersed particles, chemical instruments and methods, and combined devices. The effect of low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

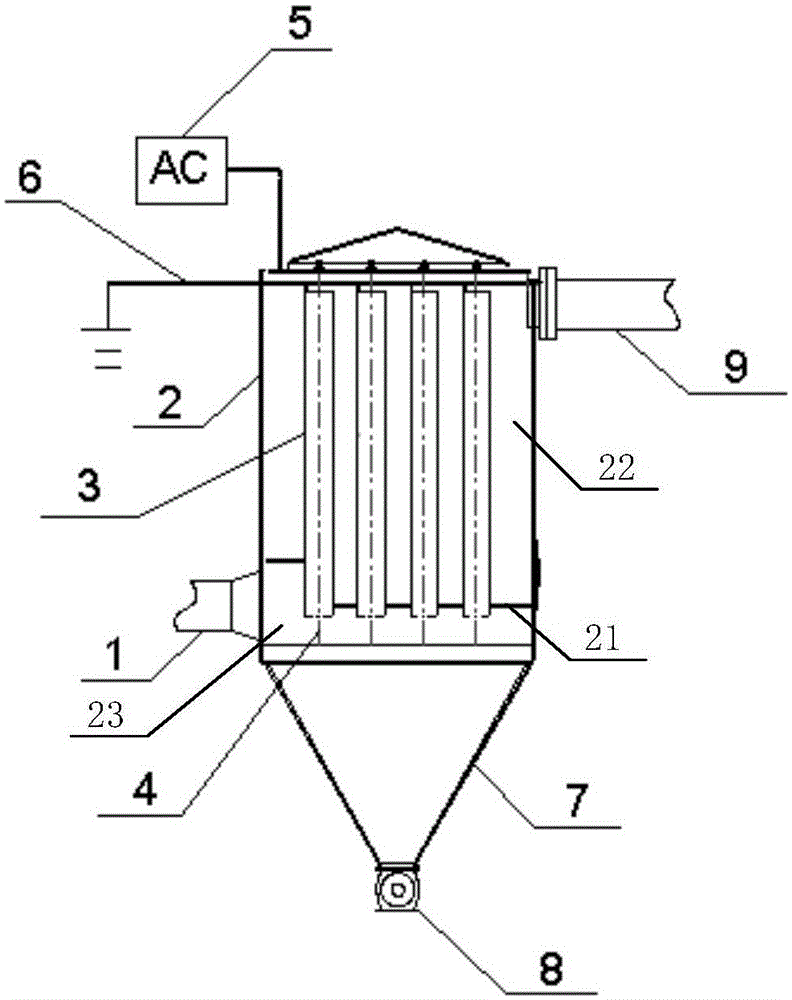

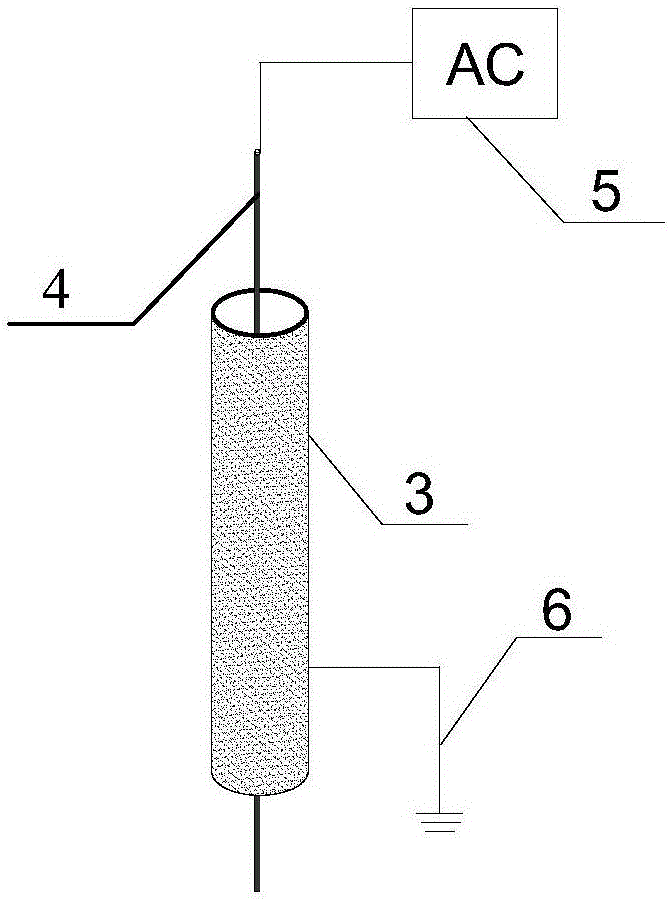

[0027] (1) The metal film filter cartridge 3 mainly has two purposes: one is as a discharge electrode for corona discharge, so that an electric field is generated in the metal film filter cartridge 3, and corona is generated with the corona wire 4 in the metal film filter cartridge 3 Discharge, so that the fine particles are charged and condensed into larger particles, which is convenient for subsequent removal; the second is as a filter material, which can remove the agglomerated and enlarged fine particles from the dusty airflow. The dust filtering mechanism of the metal film filter cartridge 3 mainly includes: firstly, the dust with a relatively large particle size forms dust bridging and deposition through screening, inertia and bonding effects, and is captured by the mesh of the surface filter layer and attached to the surface A complete dust layer is formed on the surface of the filter screen; then, the dust layer further strengthens the dust collection effect, so that th...

Embodiment 1

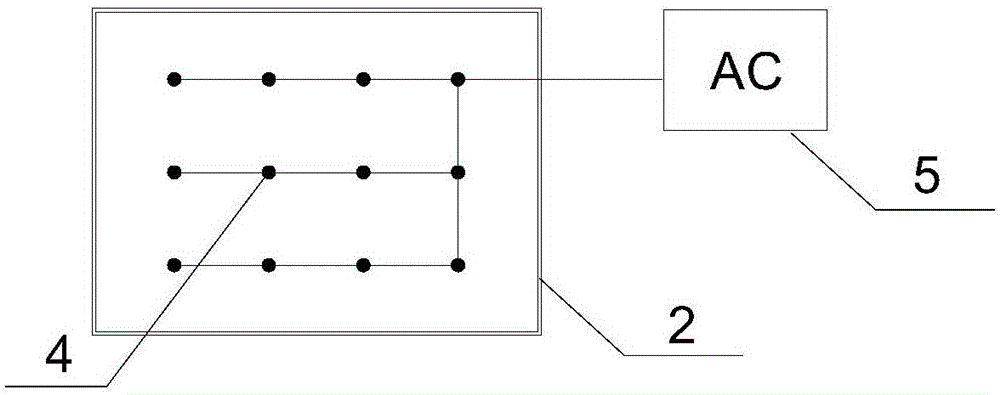

[0045] The fine particle purification equipment described in the above technical scheme is used to conduct a fine particle purification experiment on the smelting dust of a lead-zinc smelter. In this experiment, a screw conveyor is used to generate dust. There are 16 metal film filter cartridges 3 evenly distributed in the purification chamber 2 of the fine particle purification equipment, and each metal film filter cartridge 3 is made of Fe-Al sintered metal powder prepared, the input voltage of the AC high-voltage power supply 5 is 220V, the output voltage is 0-50kV, the output current is 0-200mA, the output pulse frequency is 50Hz, the filtering wind speed is 7.1m / s-9.8m / s, the dust concentration 0.4~6.5g / m 3 .

[0046] After calculation, when the filtering wind speed is 8m / s, the dust concentration is 6.5g / m 3 When changing the output voltage of the AC high-voltage power supply 5, the fine particle purification equipment will 2.5 The removal efficiencies of fine particu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com