A kind of crop seeding film

A crop and film bag technology, applied in the field of crop cultivation, can solve the problems of consuming agricultural machinery subsidies, sparse seedlings, affecting yield, etc., and achieve the effects of promoting crop growth, early maturity and easy acceptance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

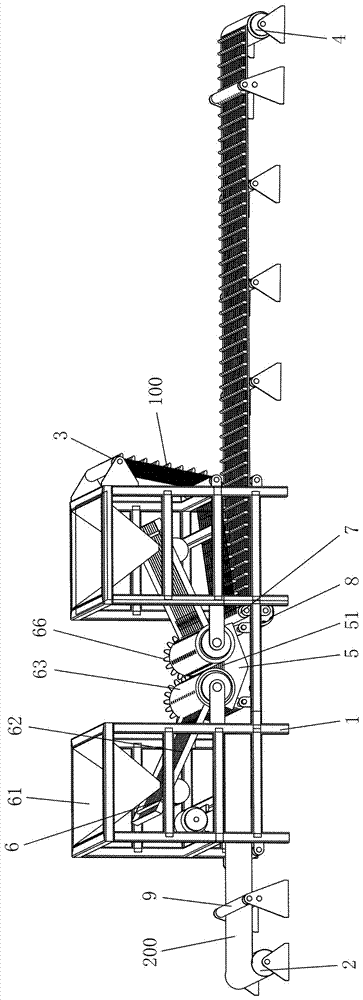

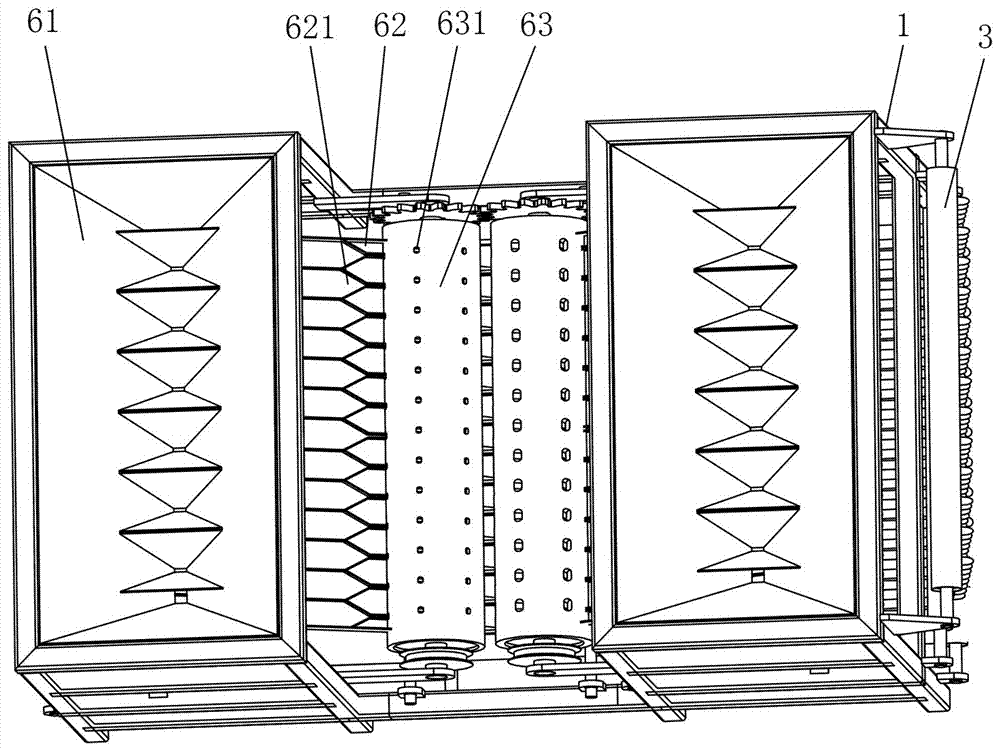

[0036] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

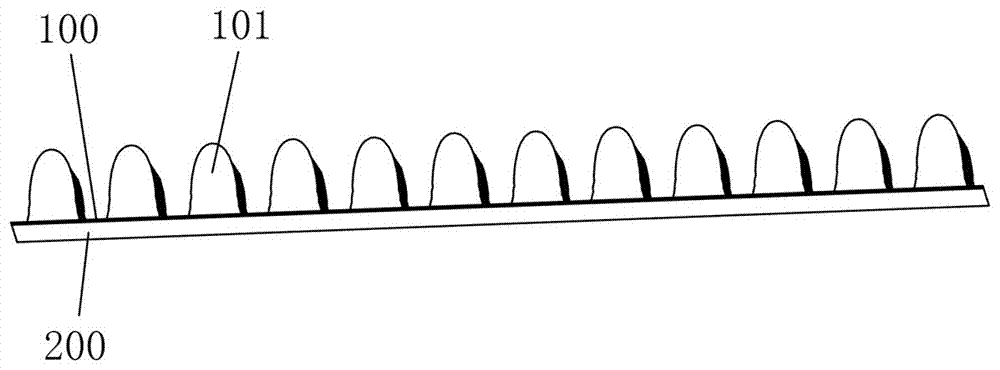

[0037] like figure 1 As shown, the crop seeding film of the present invention includes two layers of degradable films connected to each other, and a plurality of evenly distributed accommodating cavities are formed between the two layers of degradable films, and each accommodating cavity is filled with seeds, fertilizers and pesticides. During crop cultivation, the farmer flattens the field soil and spreads the crop seeding film on the field soil for normal field management.

[0038]In this embodiment, the two layers of degradable films are the degradable film 100 with a bag and the degradable film 200 with holes respectively. The degradable film 100 with a bag is provided with a number of film bags 101 evenly distributed, and the cavity of each film bag 101 is filled with seeds and fertilizers. and pesticides, the perforated degradabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com