Heat exchanger, in particular for a refrigerant circulating in a motor vehicle

A technology for heat exchangers and motor vehicles, applied in the field of exchangers, can solve the problems of not improving heat exchange efficiency and increasing the cost of exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the following description, the same reference numerals are used to designate the same or similar elements.

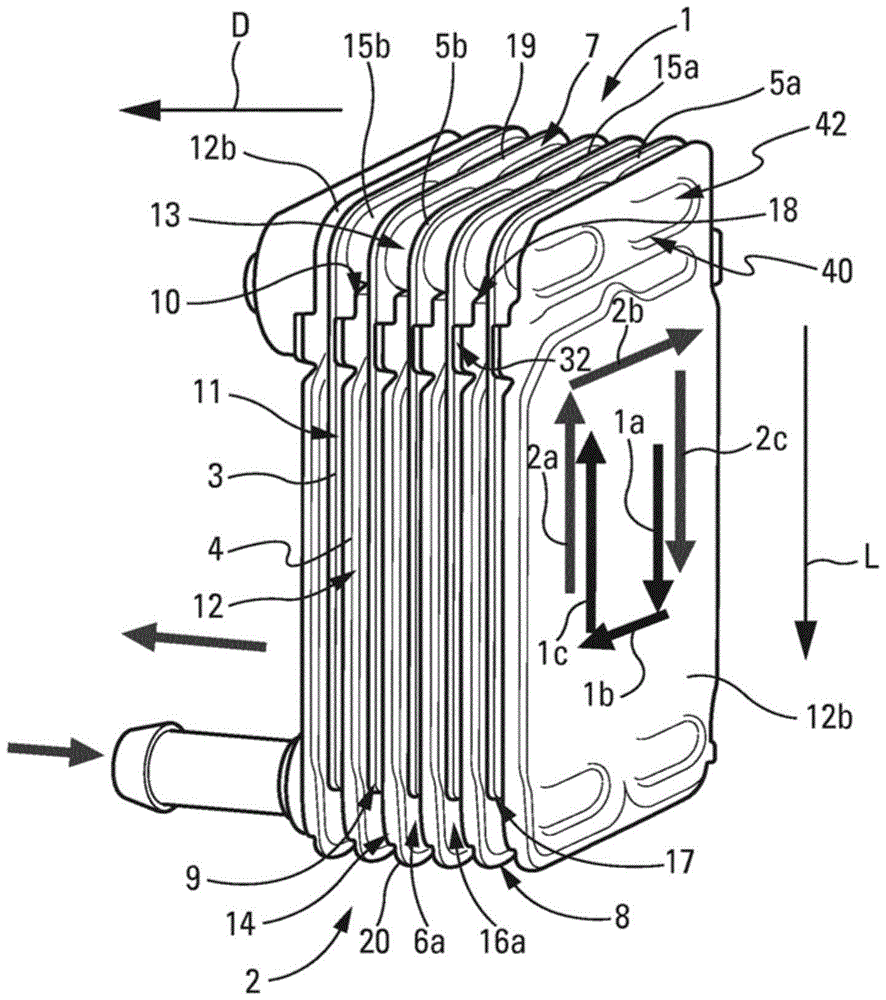

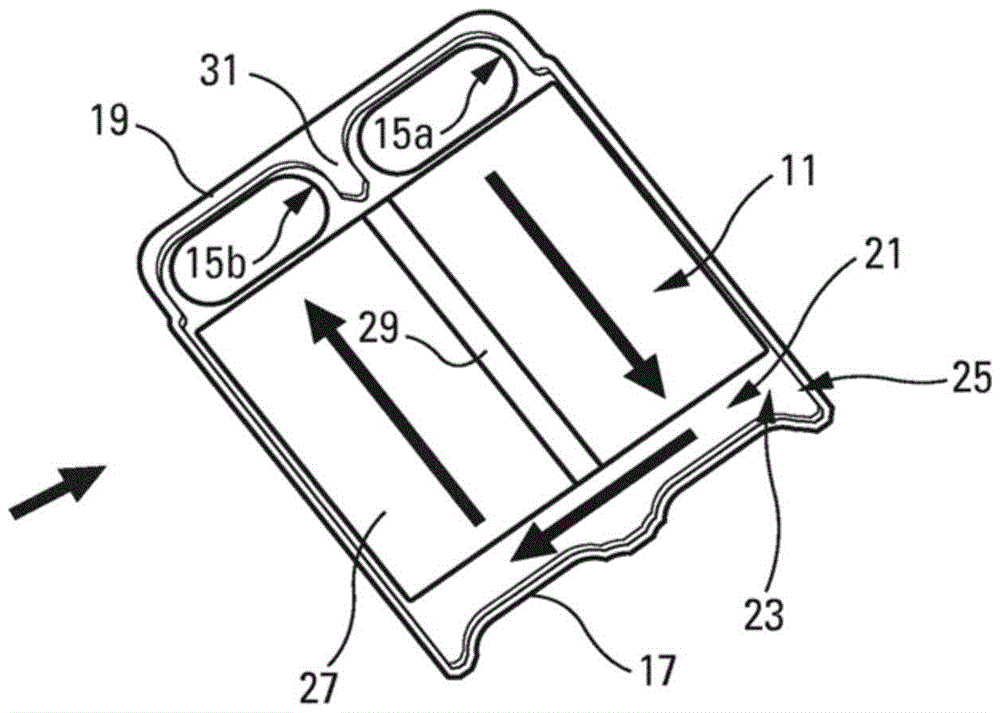

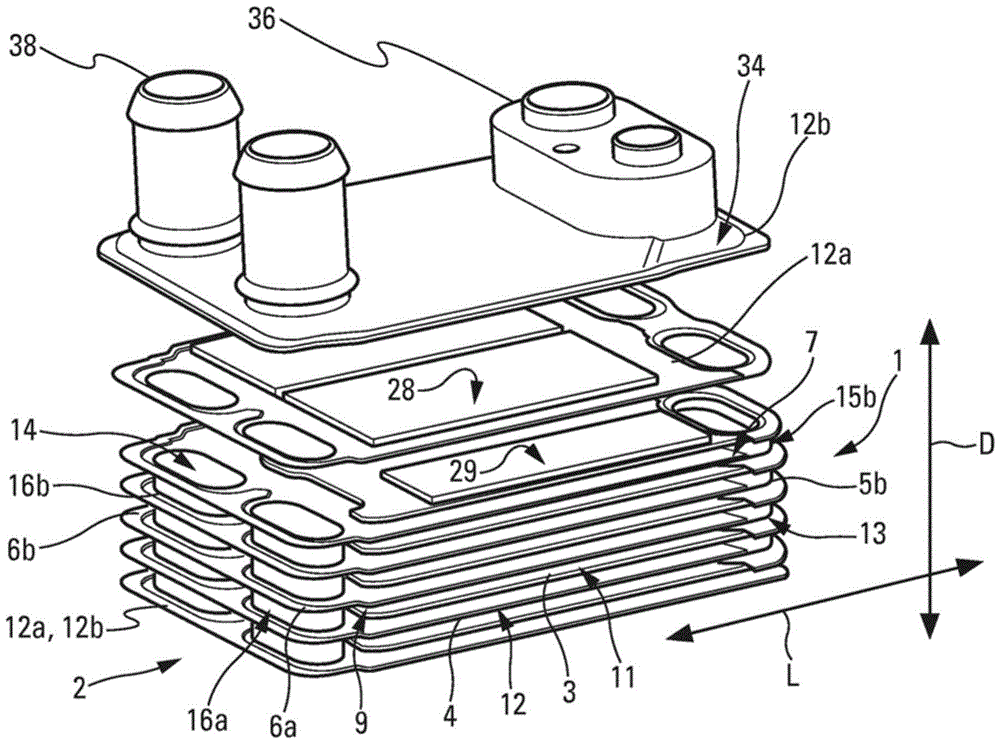

[0038] as in figure 1 with 2 As illustrated in , the invention relates to heat exchangers, in particular for refrigerants circulated in motor vehicles.

[0039] Said exchanger comprises a first unit 1 for circulating a first fluid, and a second unit 2 for circulating a second fluid, said first unit defining first vanes 3 for circulating said first fluid, Said second unit defines second vanes 4 for circulating said second fluid. The blades 3 , 4 are stacked in the stacking direction D of the blades so that heat exchange can take place between the first fluid and the second fluid.

[0040] The units 1 , 2 are formed, for example, from parts made of aluminum and / or aluminum alloys. They can be assembled, for example by brazing of the parts.

[0041] exist figure 1 In the above, the first unit 1 extends from the top to the bottom, and the second unit 2 exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com