USB 2.0 TYPE-C connector convenient for assembling welding wire

A connector and assembly welding technology, which is applied in connection, fixed connection, coupling device, etc., can solve the problems of troublesome wiring operation, large number of welding lines, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

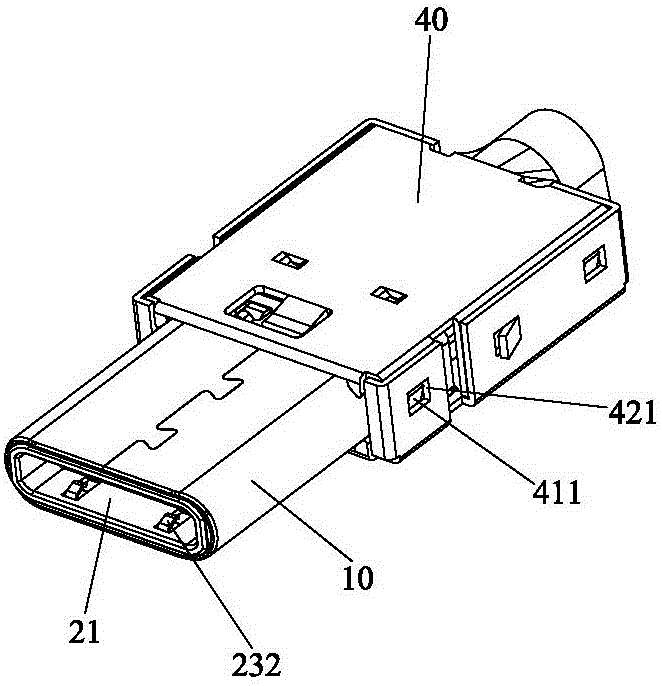

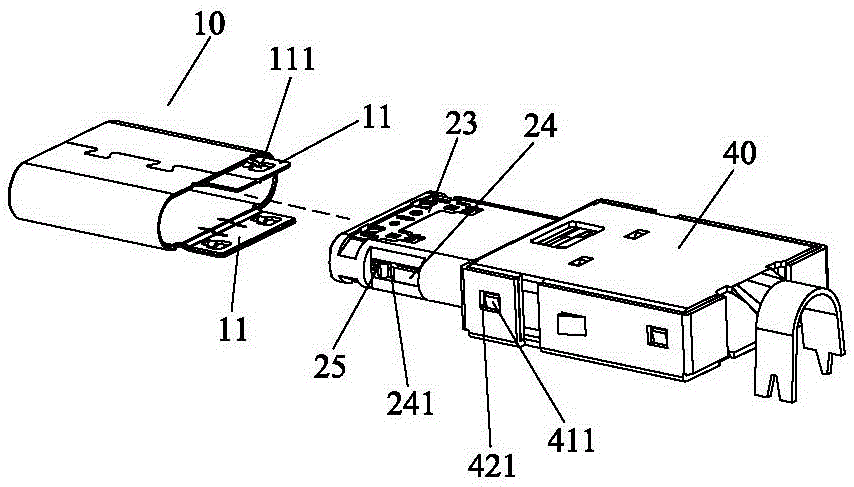

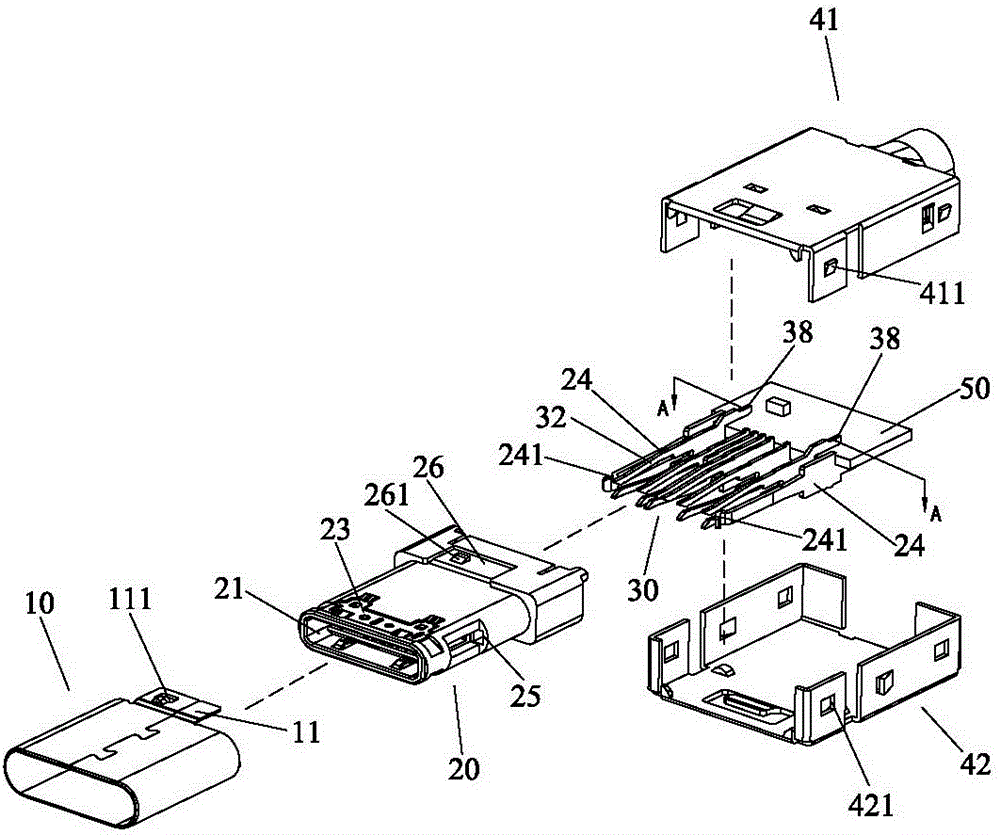

[0042] The invention is like Figure 1 to Figure 6 As shown, a USB2.0 TYPE-C connector for easy assembly of welding wires includes a shielding shell 10, an insulating body 20 installed in the shielding shell 10, a plurality of conductive terminals 30 mounted on the insulating body 20, and connecting The circuit board 50 at the rear end of the conductive terminal 30 and the housing 40 sheathed at the rear end of the insulating body 20, wherein:

[0043] A fixing plate 11 is integrally extended on the upper and lower surfaces of the rear end of the shielding shell 10 respectively, and a first button hole 111 is provided on the fixing plate 11 for relatively fixing the shielding shell 10 and the insulating body 20.

[0044] An insertion port 21 is formed at the front end of the insulating body 20, and an embedding groove 22 is recessed on the top wall and the bottom wall of the insulating body 20, and a limit piece 23 is detachably installed in each embedding groove 22. The embedding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com