Miniature quick-acting type temperature controller

A temperature controller, quick-action technology, applied in the direction of thermal switch components, etc., can solve the problems of high welding requirements, large temperature dispersion, increased process difficulties and manufacturing costs, etc., to reduce product costs and achieve high yields , The effect of small internal resistance of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

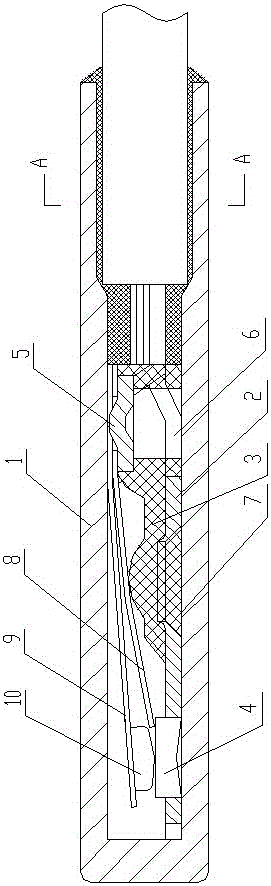

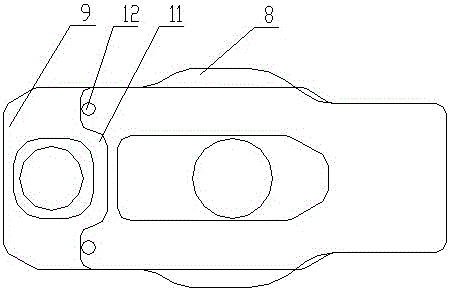

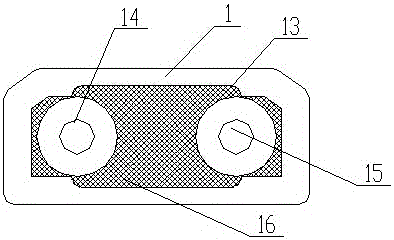

[0017] Such as figure 1 , 2 , 3, the present invention includes a housing 1 with an opening at the right end, chamfering is provided on both sides of the upper end surface of the housing 1, a metal bottom plate 2 is arranged inside the housing 1, and a base 3 and a static Contact 4, the middle part of the base 3 is provided with a boss, the end of the base 3 away from the static contact 4 is provided with a contact piece 5, and the base 3 directly below the contact piece 5 is provided with a through hole 6 as an electrode hole for welding , The metal bottom plate 2 is provided with a tapered hole 7 with a small upper opening and a large bottom opening, and the lower end of the base 3 is fitted into the tapered hole 7 of the metal bottom plate 2 .

[0018] The housing above the base 3 is provided with a spring sheet 9 and a bimetal sheet 8, the spring sheet 9 is stacked on the bimetal sheet 8, and one end of the spring sheet 9 and the bimetal sheet 8 is welded on the contact s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com