Heat-insulating property detection device and detection method

A detection device and performance technology are applied in the field of thermal insulation performance detection devices, which can solve the problems of difficult identification of thermal insulation films, poor thermal insulation performance, etc., and achieve the effects of simple and accurate methods, improved promotion, and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

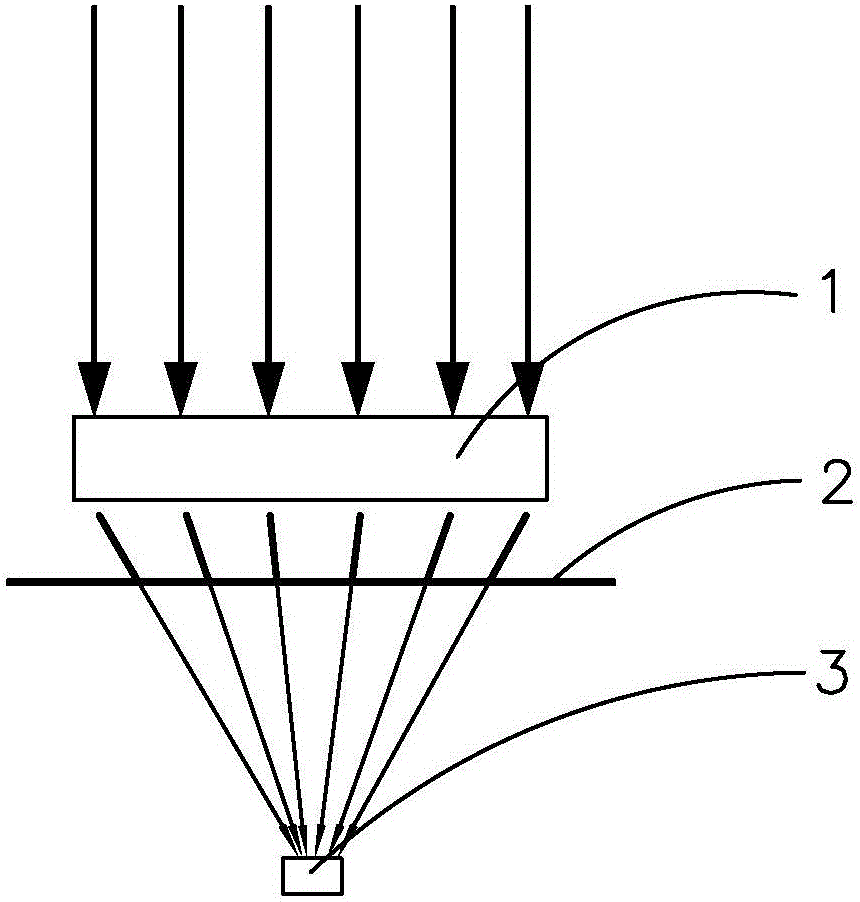

[0025] Take a black translucent magnifying glass 1 with a diameter of 10cm to focus the sunlight and focus it on the leaves. Within the time T1, the leaves will be scorched and burnt holes will appear. Place a heat-insulating film in front of the magnifying glass 1, and then focus the transmitted sunlight on the same leaf and grill for the same time T1, and compare the burnt degree of the leaves before and after placing the heat-insulating film. Place the heat insulation film with good heat insulation performance, the focused light spot of the magnifying glass 1 will not scorch the leaves, but the heat insulation film with general heat insulation performance will scorch the leaves to varying degrees. The time T1 can be extended appropriately to further judge the heat insulation performance of the heat insulation film.

Embodiment 2

[0027] Take the transparent lens magnifying glass 1 to focus sunlight, install a temperature sensor on the focused light spot, place different coated glasses in front of or behind the magnifying glass 1, compare the temperature displayed by the temperature sensor within the same time T2, and judge the temperature of different coated glasses insulation performance.

Embodiment 3

[0029] Turn on the infrared transmitter to radiate infrared rays, take the transparent lens magnifying glass 1 to focus the infrared rays, place the heat insulation film in front or behind the magnifier 1, and judge the heat insulation performance of the heat insulation film by feeling the temperature of the focused light spot on the skin within time T3.

[0030] The device and method use a magnifying glass to focus sunlight or infrared rays radiated by an infrared emitter, and judge the heat insulation performance of the heat insulating part according to the heat difference of the focused light when the light is blocked by the heat insulating part and not blocked, and the magnifying glass makes the remaining heat The difference is magnified and easy to compare. The heat insulation performance detection method and device provided by the present invention are simple and easy to implement, intuitive and accurate, the device is easy to operate and easy to obtain, and easy to promo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com