Improved compressor

A compressor and improved technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as increased noise power level of compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

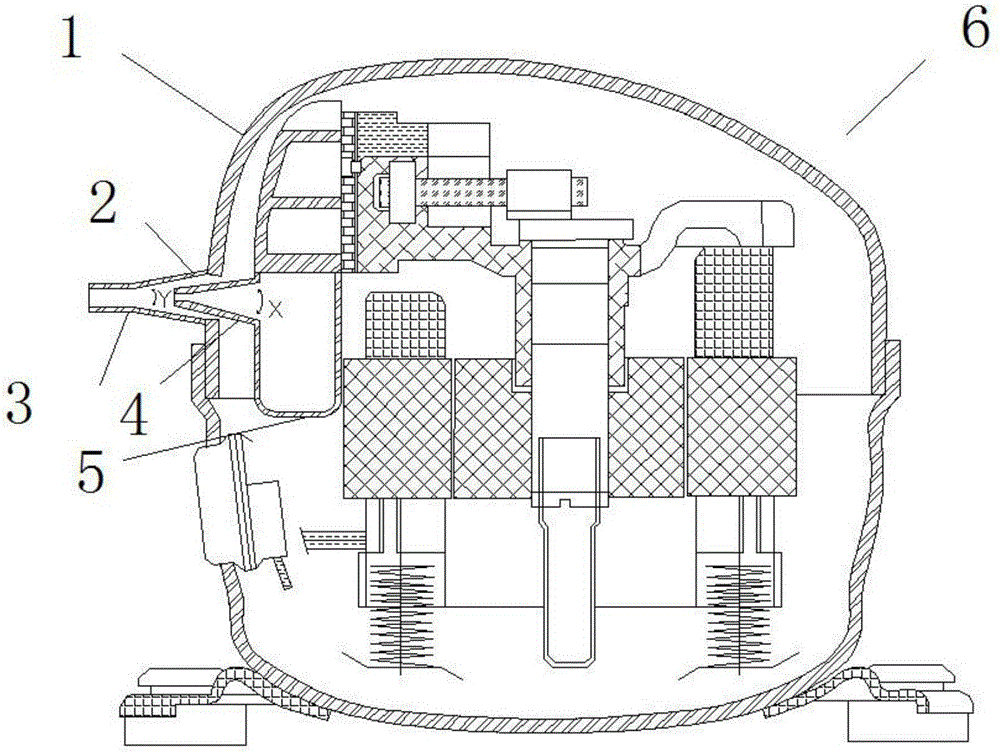

[0022] see figure 1 , the compressor 6 includes: a casing 1; a muffler 5 disposed inside the casing 1, which attenuates noise due to the refrigerant fluid; an inlet pipe 3, which carries the refrigerant fluid delivered from the evaporator in the refrigeration cycle; an opening 2, which is arranged at the position where the inlet pipe 3 is installed on the shell 1, and provides the inlet of the refrigerant fluid to the shell 1.

[0023] The compressor 6 also includes a muffler pipe 4 , one end of which leads to the muffler 5 , the other end of which extends through the opening 2 to the outside of the housing 1 and leads to the inlet pipe 3 with a gap between them. The muffler pipe 4 extends from outside the casing 1 all the way into the inlet pipe 3 and almost all of the refrigerant fluid sucked by the compressor 6 is received directly into the muffler 5 without entering the casing 1 . With the muffler pipe 4 the inlet of the muffler 5 extends all the way into the inlet pipe 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com