GIC measuring method and device for buried oil-gas pipeline and cathodic protection device

A cathodic protection, oil and gas pipeline technology, applied in the field of GIC monitoring of buried oil and gas pipelines, can solve the problems of corrosion, pipeline oil and gas leakage, accelerated corrosion of metal pipelines, etc., and achieve the effect of avoiding major accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

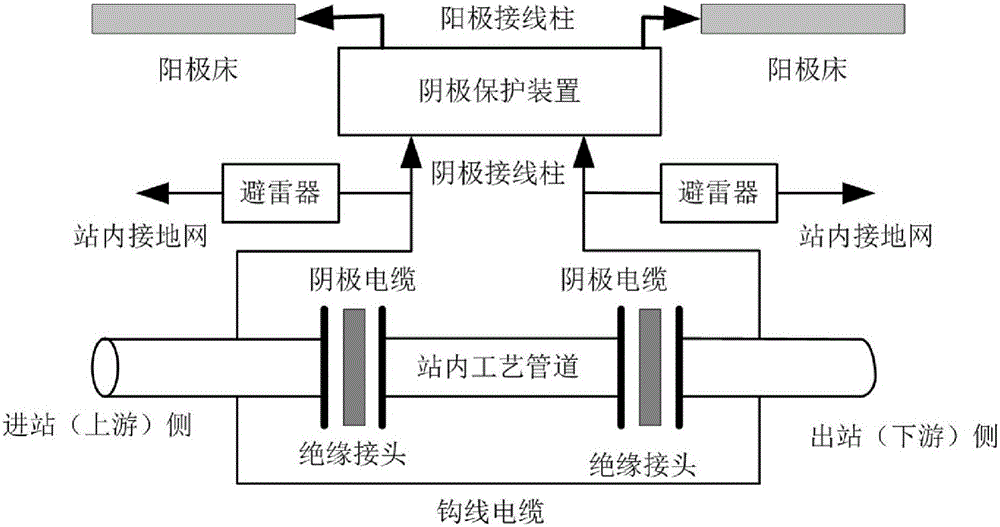

[0045] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The following description is only for demonstration and explanation, and does not limit the present invention in any form.

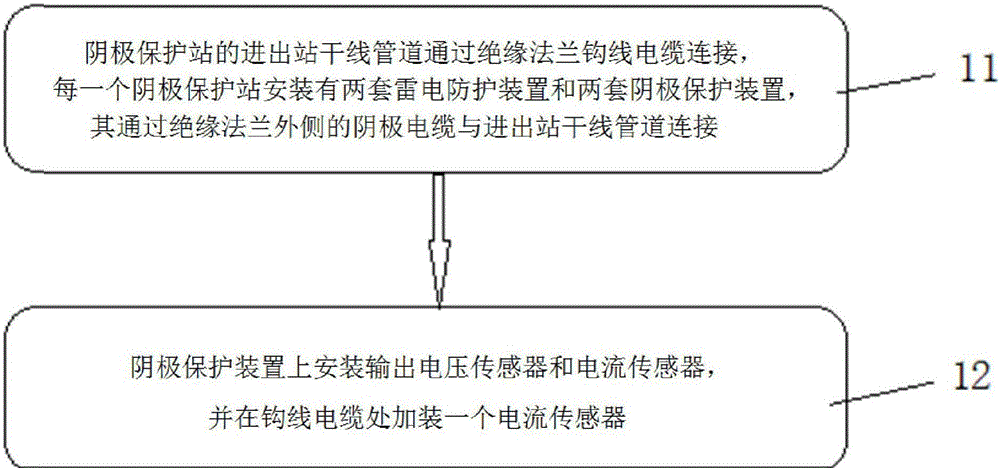

[0046] like figure 1 As shown, the GIC measurement method of buried oil and gas pipelines and cathodic protection devices includes steps 1 and 2:

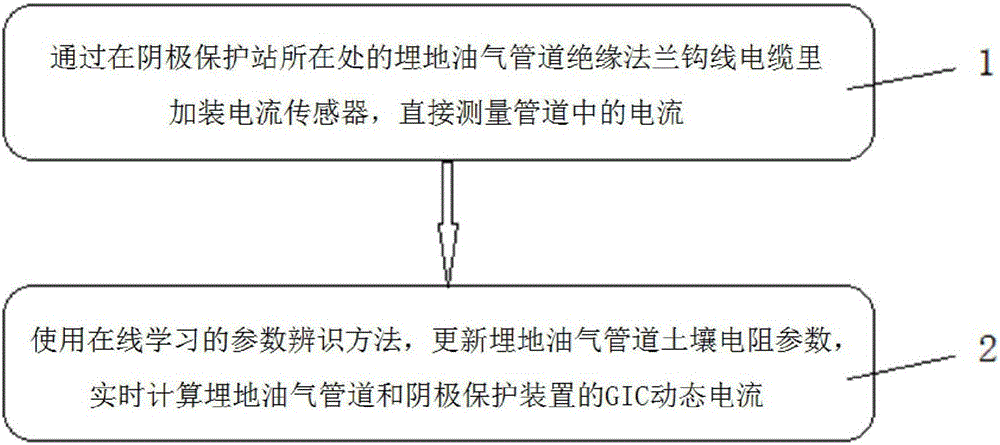

[0047] Step 1, directly measure the current in the buried oil and gas pipeline by installing a current sensor in the insulated flange hook wire cable of the buried oil and gas pipeline where the cathodic protection station is located;

[0048] Step 2, using the parameter identification method of online learning, update the soil resistance parameters of the buried oil and gas pipeline, and calculate the GIC dynamic current of the buried oil and gas pipeline and the cathodic protection device in real time.

[0049] Generally, the process pipeline in the pigging station (cathodic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com