Automatic sorting vibrating disk capable of adjusting feeding speed of nut

A technology for automatically sorting and adjusting nuts, applied to vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of assembly and processing safety hazards, inability to accurately position nuts, low feeding efficiency, etc., to achieve simple structure and save manpower The effect of high material resources and high feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

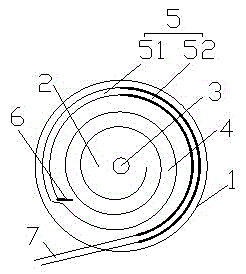

[0009] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an automatic sorting vibrating plate for adjusting the feeding speed of nuts proposed by the present invention.

[0010] refer to figure 1 , the present invention proposes an automatic sorting vibrating plate for adjusting the feeding speed of nuts, comprising: a hopper 1, a chassis 2, a driving device 3, a feeding guide rail and a feeding pipe 6 and a controller; the hopper 1 is installed on the chassis 2, and the driving device 3 Drive and connect the chassis 2 to make the hopper 1 do torsion movement, and the controller is connected to the driving device; the hopper 1 is respectively provided with a first spiral guide rail 4 and a second spiral guide rail 5 from the inside to the outside, the first spiral guide rail 4 and the second spiral guide rail 5 The inner height of the spiral guide rail 5 is higher than the height of the outer side, the first spiral guide rail 4 is a spiral rising st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com