Crawler-type sorting equipment with belt quick positioning and loading-unloading device

A loading and unloading device and crawler-type technology, which is applied in the field of sorting equipment, can solve the problems of not considering the installation and maintenance of belt conveyors, affecting the sorting effect, and complicated disassembly process, so as to improve the quality of installation and maintenance, improve the experience and guarantee effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

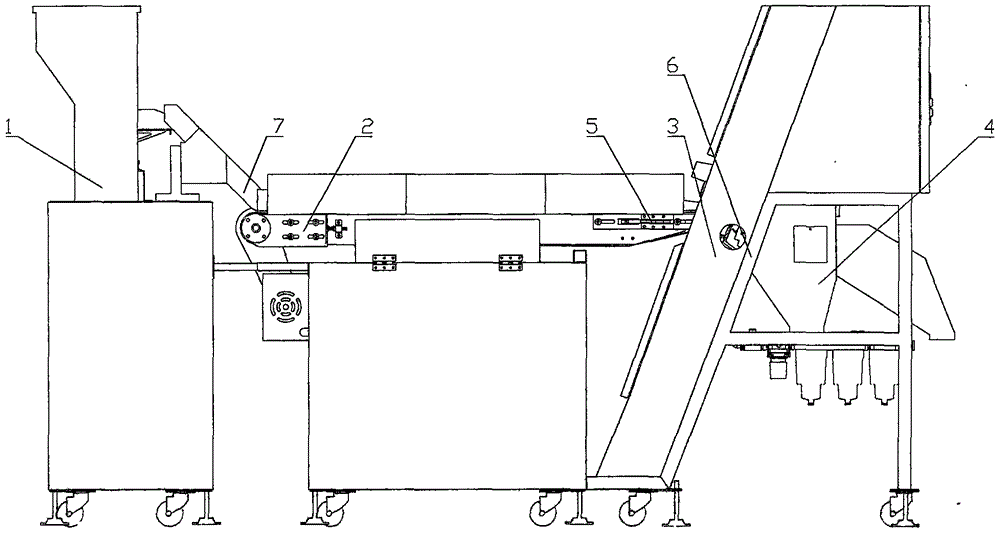

[0027] refer to figure 1 with figure 2 As shown, the present invention provides a crawler-type sorting device with a belt quick positioning loading and unloading device, comprising: a feeding mechanism 1; a belt conveying mechanism 2, which is arranged at the rear end of the feeding mechanism 1; an identification and sorting mechanism 3, It is arranged on the belt outlet end of the belt conveying mechanism 2; the discharge mechanism 4, which is fixed on the support frame 6 of the identification and sorting mechanism 3, and is at the outlet end of the belt conveying mechanism 2; and is located on the belt conveying mechanism 2 The belt fast positioning loading and unloading device 5 at the driven end of the conveyor belt.

[0028] Specifically, the belt quick positioning loading and unloading device 5 includes a positioning unit for positioning the length of the belt, and an auxiliary adjustment unit for assisting installation and disassembly, and the positioning unit is conn...

Embodiment 2

[0034] refer to image 3 with Figure 4 As shown, the other structure of this embodiment is the same as that of Embodiment 1, the difference is that this embodiment also includes a height adjustment mechanism 8, and the height adjustment mechanism 8 is provided with two height adjustment brackets 801, and the height adjustment bracket 801 One end is hinged on the belt conveying mechanism 2, and the other end is installed on the transmission frame 9 through the bracket fixing plate 802. The bracket fixing plate 802 is provided with a waist-shaped slotted hole, and the installation and fixing position of the waist-shaped slotted hole is adjusted. To achieve the purpose of height adjustment. The belt conveyor mechanism 2 is driven by the height adjustment mechanism 8 to adjust up and down on the transmission frame 9, so that the outlet end of the belt conveyor mechanism 2 is located in the optimal range of the identification and sorting mechanism 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com