Automatic express bill pasting equipment

A technology of automatic pasting and equipment, applied in labeling machines, labels, packaging, etc., can solve the problems of wasting manpower and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

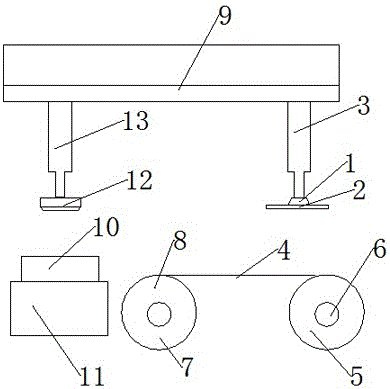

[0016] Automatic sticking equipment for courier slip 2, including: plastic tape 4 components for removing release paper on courier slip 2, workbench 11 for placing courier packages next to plastic tape 4, plastic tape 4 components and moving parts on workbench 11 , is connected to the suction part and the thermal printer 12 on the moving part. As a preference, the moving part is a guide rail 9, and the suction part is a vacuum chuck 1. The vacuum suction cup 1 sucks the side of the courier 2 to be printed, and the side of the release paper is stuck by the plastic tape 4. When the guide rail 9 is removed, the release paper is still stuck on the plastic tape 4, and the courier 2 is taken away and placed on arrival. The workbench 11 of the package 10 is pasted, and the vacuum suction cup 1 and the thermal printer 12 are fixed on the two sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com