Injection mold allowing insert to be installed and dismantled quickly

A technology for injection molds and inserts, applied in the field of molds for injection molding, can solve the problems of destroying the structural strength and sealing performance of the main body of the mold, insufficient utilization of mold resources, shortening the service life of the mold, etc., and achieves improved use flexibility and simple structure. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

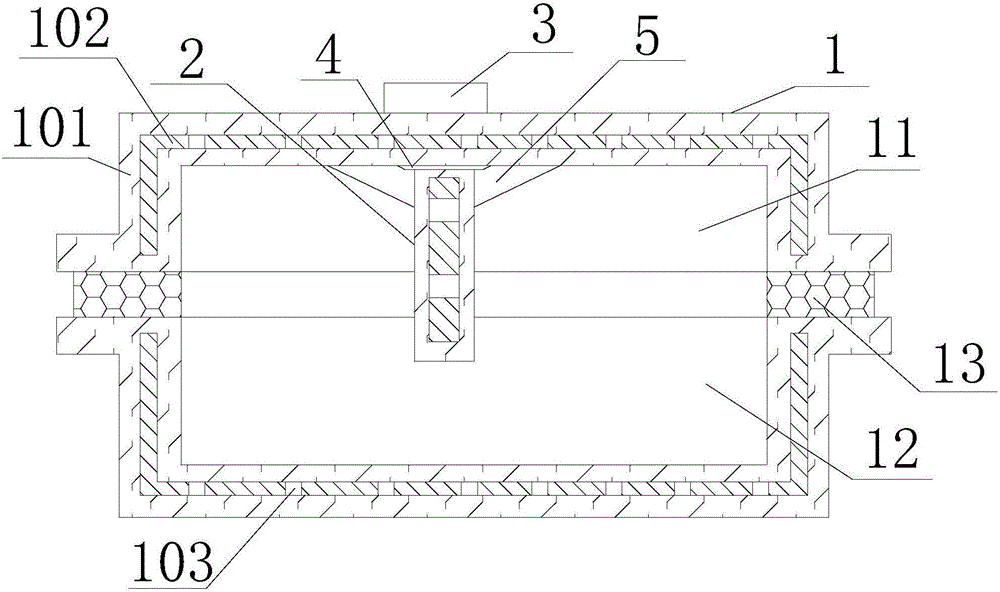

[0015] like figure 1 The injection mold for quick disassembly and assembly of inserts includes a main mold body 1, an inlaid structural part 2 and a positioning electromagnet 3, and the main mold body 1 and the inlaid structural part 2 both include a base material 101 and a magnetic metal rib 102, the base material 101 is coated on the outside of the magnetic metal rib plate 102, and the maximum distance between the magnetic metal rib plate 102 and the surface of the base material 101 is not more than 10 mm, the main mold body 1 is a closed cavity structure, and the mosaic structure 2 is embedded in the main mold body. In the mold body 1, and offset against the inner surface of the main mold body 1, a vacuum suction cup 4 is additionally provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com