Assembly positioning tool and assembly method for four-bar linkage hood hinge

An assembly method and four-bar linkage technology are applied in the direction of manufacturing tools, hand-held tools, etc., to achieve the effects of improving assembly efficiency, promoting value, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

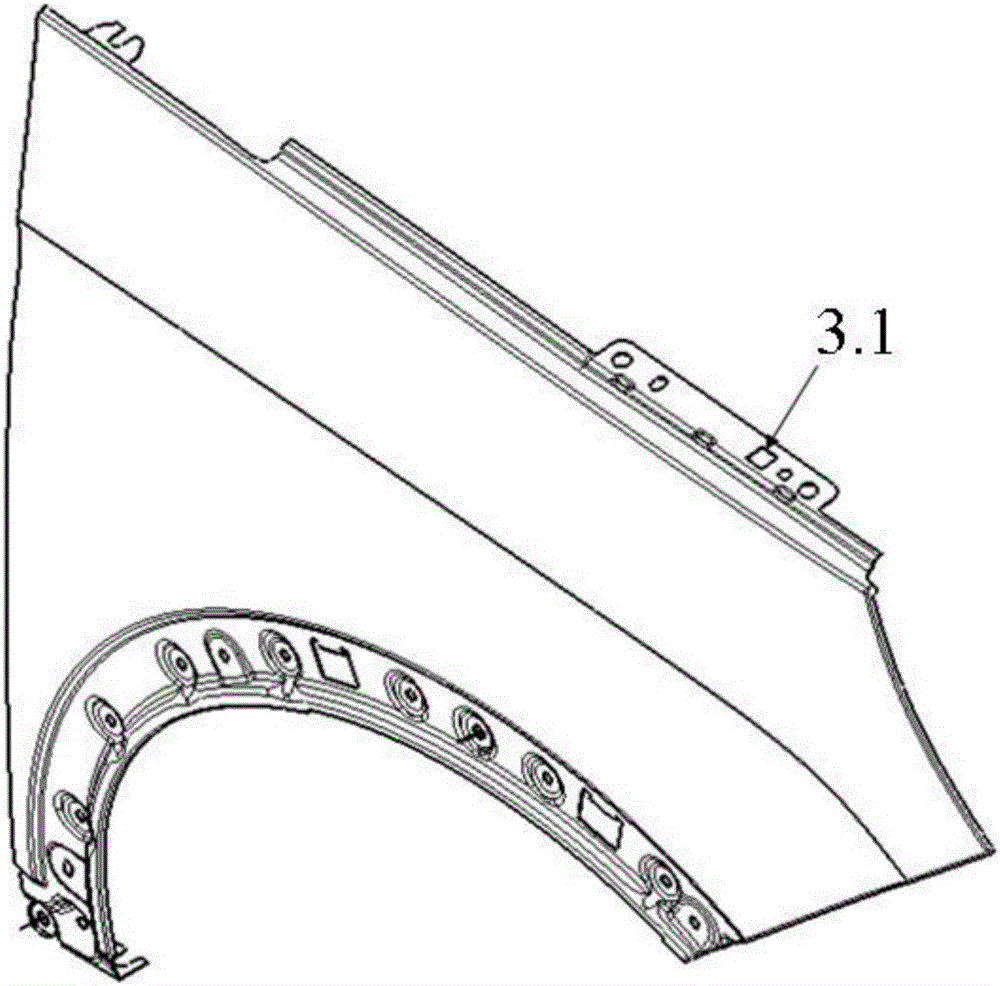

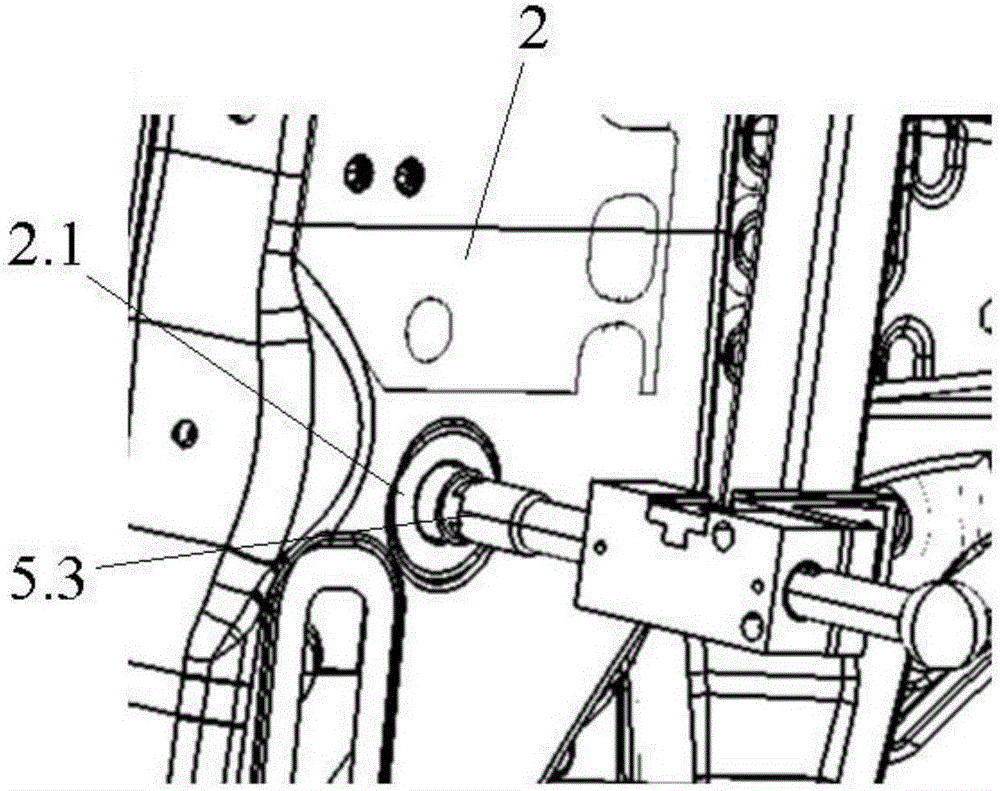

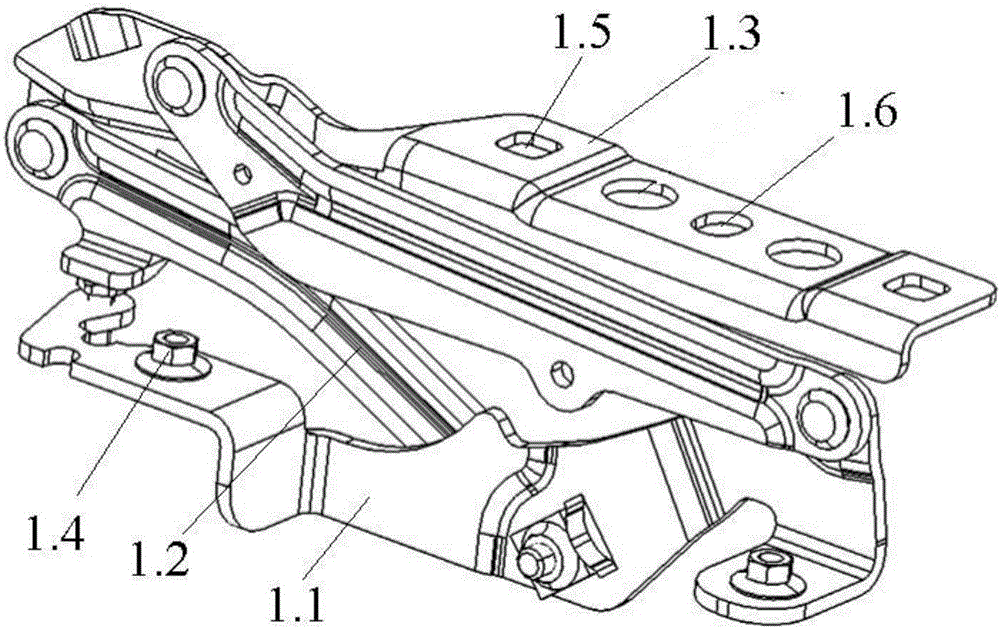

[0054] Such as Figure 7-20 , an assembly and positioning tool for a four-bar linkage hood hinge, including a first sample frame 5 and a second sample frame 6, the first sample frame 5 is used to position and install the movable page 1.3 of the hinge 1, and the second sample frame 6 is used to position and install the hood 4 of the hinge 1, in actual use, such as Figure 7-8 As shown, the first sample frame 5 is fixed on the vehicle body 2, and the distance between the first sample frame 5 and the A-pillar of the vehicle body is determined. The distance between is determined.

[0055] Such as Figure 7-8 As shown, the first sample frame 5 includes a first bracket 5.1 assembled from a plurality of rods criss-crossing and crisscrossing. The first bracket 5.1 is made based on the shape of the hood 4 when it is in a closed state. 2 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com