Welding method for reinforcement cage for concrete pile foundation

A steel cage and concrete technology, applied in welding equipment, manufacturing tools, metal processing, etc., can solve the problems of inability to realize the effective assembly of steel rings and longitudinal bars, and difficulty in adapting to the welding of longitudinal bars of different sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objects and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention.

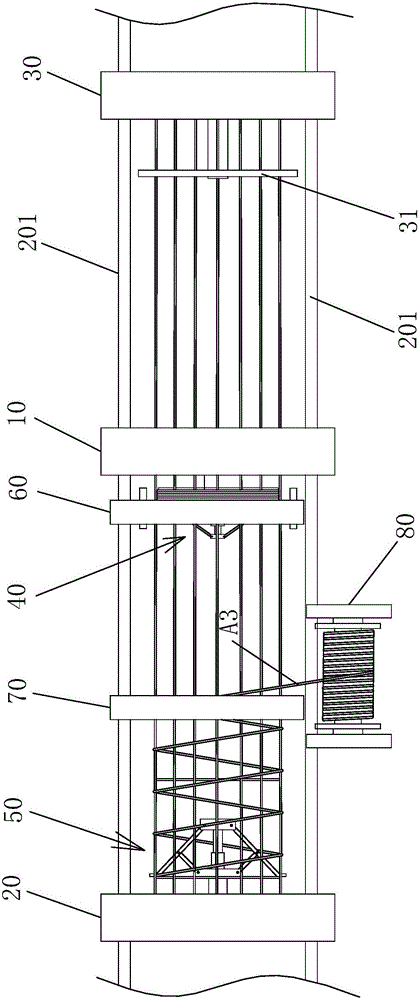

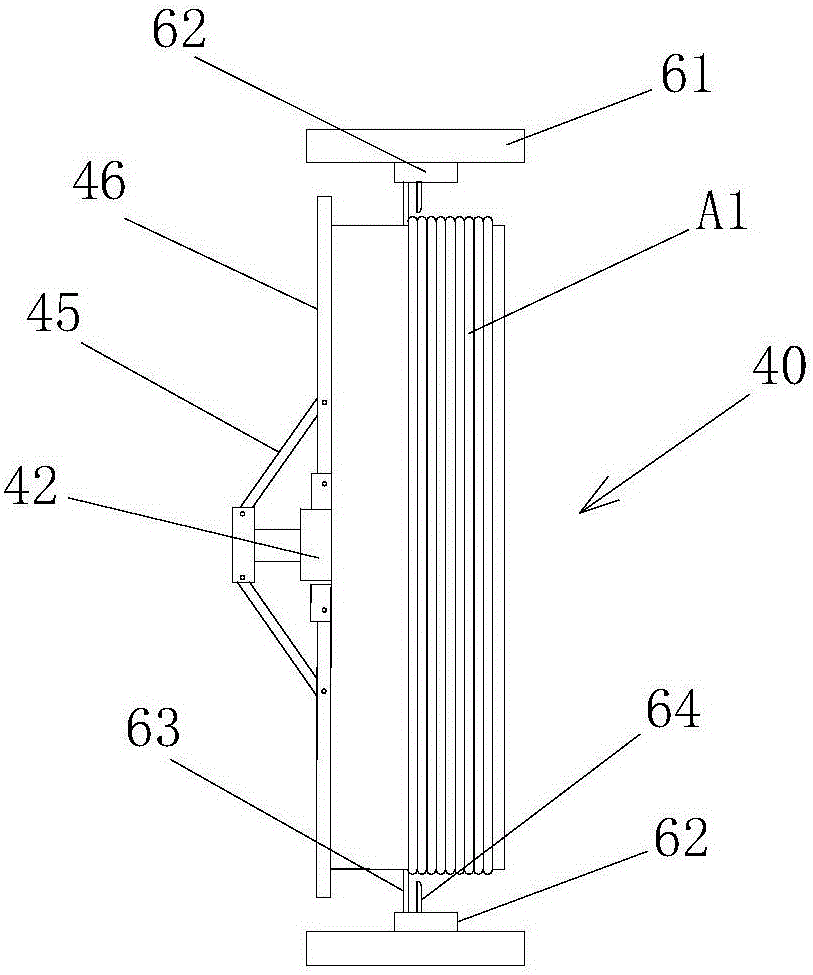

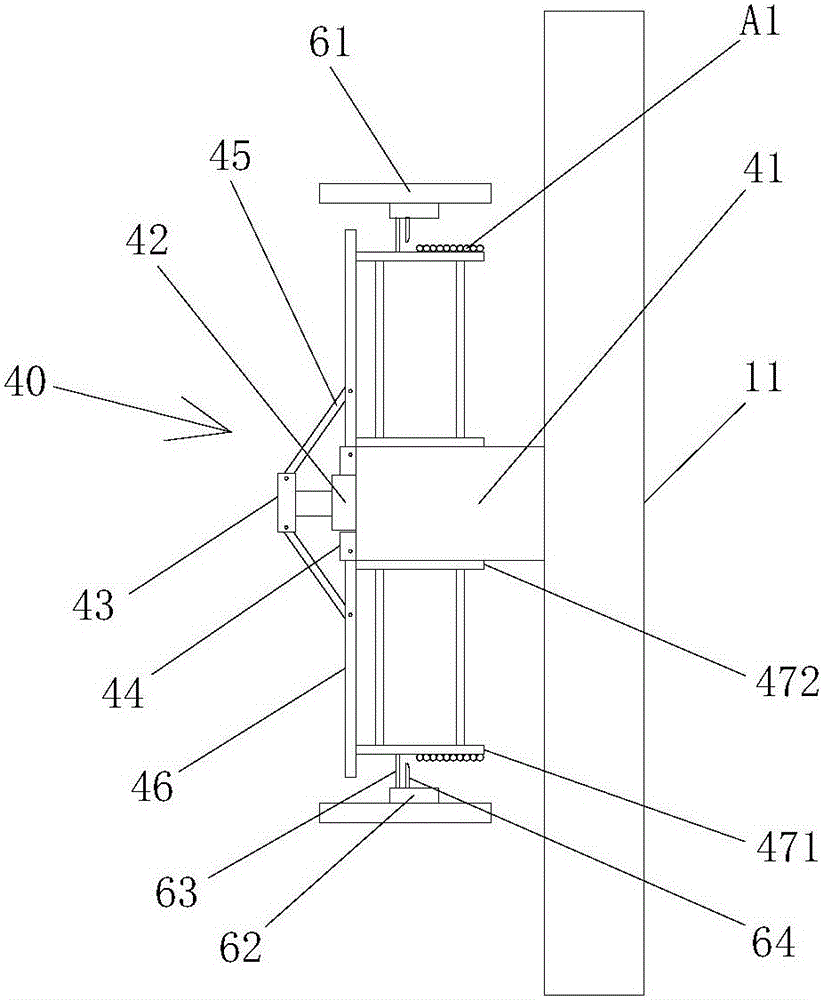

[0027] Construction pile foundation reinforcement cage welding equipment provided by the invention, such as figure 1 As shown, it includes a fixed mounting base 10 and a movable mounting base 20 arranged oppositely, the movable mounting base 20 is installed on the first slide rail 201, and the first slide rail 201 is along the distance direction between the fixed mounting base 10 and the movable mounting base 20 Arrangement, the first drive mechanism drives the movable mount 20 to move, and the first drive mechanism can be driven by a motor or a cylinder; the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com