Self-cleaning powder supply center

A powder supply center, automatic cleaning technology, applied in the direction of cleaning hollow objects, liquid supply devices, cleaning methods and utensils, etc., can solve the problems of cumbersome, low degree of automation, external environmental pollution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

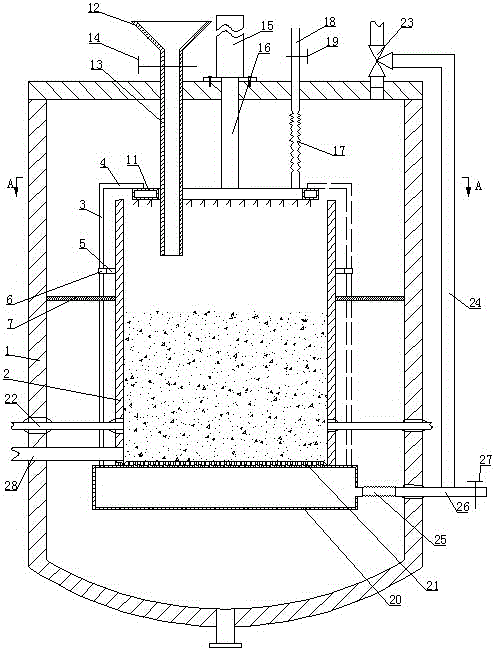

[0019] As shown in the figure, the powder supply center that can be cleaned automatically includes a cylindrical powder bucket 2 and a pressure-holding shell 1 that are coaxially arranged. The powder bucket 2 is suspended in the pressure-holding shell 1. Here, Suspension means that the outer diameter of the powder barrel 2 is smaller than the inner diameter of the pressure-holding shell 1, and the top and bottom of the powder barrel 2 and the top and bottom of the pressure-holding shell 1 respectively retain a certain gap, so that the outer surface of the powder barrel 2 is in contact with the pressure-holding shell 1. An entire pressure-stabilizing chamber is formed between the inner surfaces of the pressure-holding shell 1 . In this embodiment, two horizontal support rods 7 are fixedly connected to the outer surface of the powder bucket 2 , and the other end of the support rods 7 is fixedly connected to the inner surface of the pressure-holding housing 1 to realize the suspen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com