Round valve tray

A floating valve tray and circular technology, applied in chemical/physical/physical chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of unsatisfactory handling of air flow by float valves, insufficient gas-liquid contact, Problems such as irregular airflow rise to achieve the effect of reducing the amount of mist entrainment, fine and uniform airflow dispersion, and promoting continuous renewal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

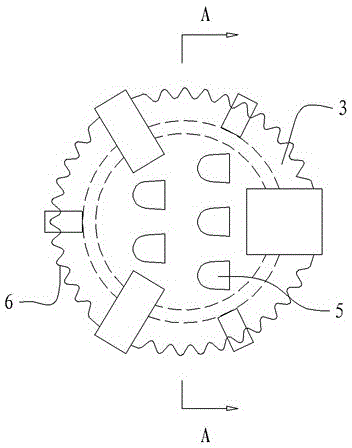

[0019] The circular valve tray of the present embodiment, such as Figure 1 to Figure 4 As shown, it includes a tray 1 and a float valve 2 that can move up and down. The tray 1 is formed with an installation hole for the installation of the float valve. The float valve 2 includes a circular valve cover 3 arranged above the tray 1 and a valve leg 4 extending downward from the periphery of the valve cover to the bottom of the tray. The valve legs 4 are distributed at intervals along the periphery of the valve cover 3 .

[0020] The valve cover 3 is provided with at least two upwardly arched tongue holes 5, and the periphery of the valve cover 3 is provided with a downwardly folded serrated edge 6, which is used to abut against the tower when the float valve 2 falls. plate 1 upper surface.

[0021] A ring of protrusions 7 is fixed on the bottom surface of the valve cover 3 , and the tongue hole 5 is located in the ring of protrusions 7 of the valve cover 3 . The circle of prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com