Round diversion damping valve tray

A float valve tray and damping technology, which is applied in the field of general physical separation operation devices, can solve the problems of unsatisfactory air flow treatment by float valves, uneven air distribution, and irregular air rise, so as to reduce the amount of mist entrained, Promotes continuous renewal and reduces the effect of mist entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

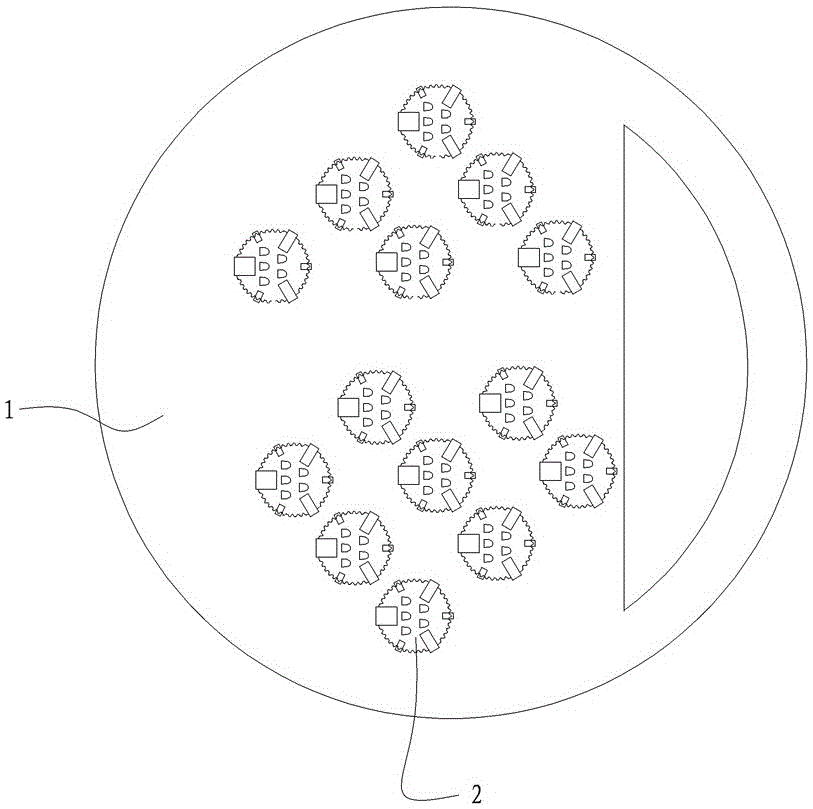

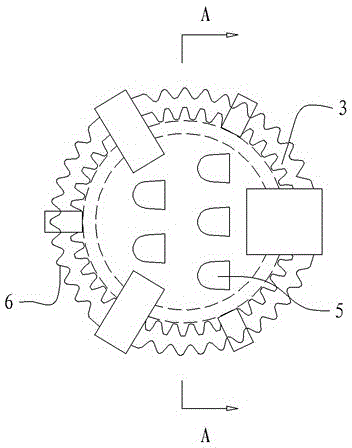

[0019] The circular shunt damping valve tray of this embodiment, such as Figure 1 to Figure 4 As shown, it includes a tray 1 and a float valve 2 that can move up and down. The tray 1 is provided with mounting holes for installing the float valve. The float valve 2 includes a circular valve cover 3 arranged above the tray 1 and a valve leg 4 extending downward from the periphery of the valve cover to the bottom of the tray. The valve legs 4 are distributed along the periphery of the valve cover 3 at intervals.

[0020] The valve cover 3 is provided with at least two upwardly arched tongue holes 5, and the periphery of the valve cover 3 is provided with a sawtooth edge 6 that is turned down. The sawtooth edge 6 of the valve cover is used to abut the tower when the float valve 2 falls The upper surface of the board 1.

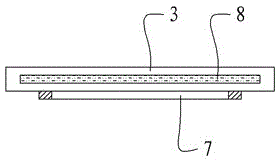

[0021] A ring of protrusions 7 is fixed on the bottom surface of the valve cover 3, and the tongue hole 5 is located in the ring of protrusions 7 of the valve cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com