A high-efficiency filter press

A filter press, high-efficiency technology, applied in the field of filter press, can solve the problems of long working time, low efficiency, low dehydration efficiency of filter press, etc., and achieve the effect of easy operation, reliable and simple structure, and reduced maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

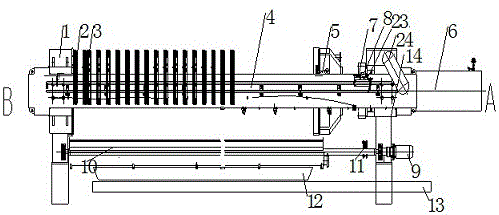

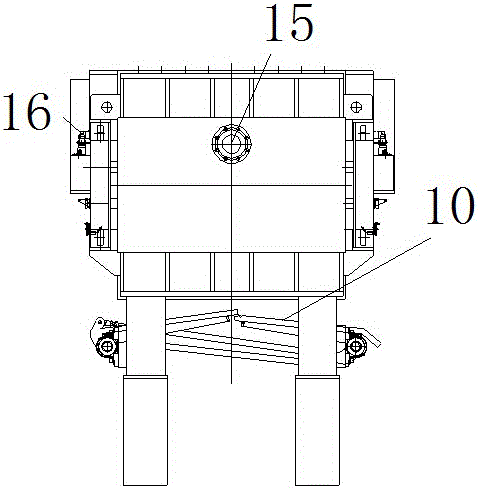

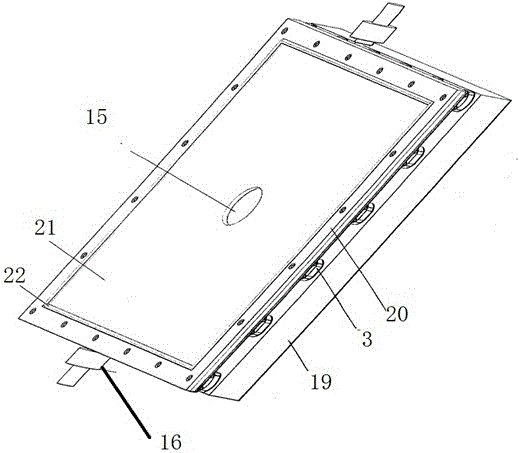

[0022] Please refer to figure 1 to Figure 4 As shown, in this implementation case, a high-efficiency filter press includes a frame, and the frame 14 is designed with two main beams 4 along the horizontal direction, and the B end of the main beam 4 is designed with a thrust plate 1 , A end of the main beam 4 is designed with a push plate 5, the push plate 5 is driven by the main oil cylinder 6, a plurality of filter plate units 2 are connected between the thrust plate 1 and the push plate 5, and the two ends of the filter plate unit 2 are designed with The roller 16 and the track matched with the roller, the filter plate unit 2 has a feed inlet 15, the filter plate unit 2 is composed of the main filter plate 19, the lining plate 21, and the plate frame 20, and is combined into a whole filter plate through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com