Method for continuously and comprehensively extracting liquorice ingredient with high pressure

A comprehensive extraction and high-pressure technology, applied in the separation and extraction of licorice components, can solve the problems of no continuity in the primary extraction process, large-scale production, and small amount of experiments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

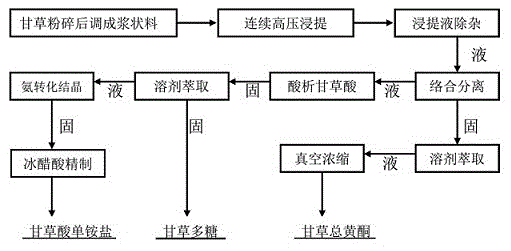

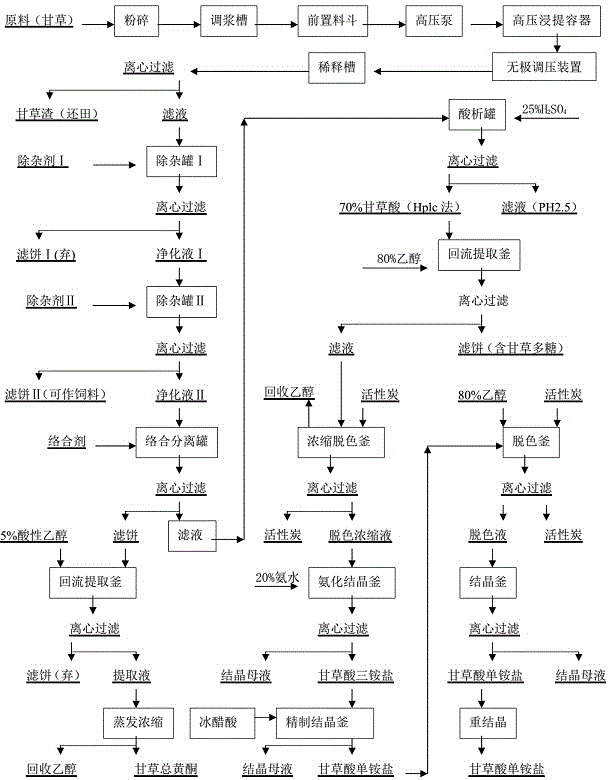

[0017] Please also see figure 1 and figure 2 , The method of continuous high-pressure comprehensive extraction of licorice components includes the following steps:

[0018] Continuous high-pressure extraction: After crushing the licorice, the crushed licorice is adjusted into a slurry with a predetermined amount of water, and the slurry is pushed into the high-pressure extraction vessel by a high-pressure pump at room temperature, and the slurry is pressed for a predetermined time Continuous feeding and discharging inside to achieve fluid leaching, and then obtain slurry high pressure leaching material. Among them, the licorice is crushed to 60-80 mesh, the quality of the licorice powder is 0.25 times that of water, the pressure in the high-pressure extraction vessel is 120-150 MPa, and the predetermined length of time for pressing is 3-8 minutes.

[0019] Two-stage flocculation and impurity removal: the slurry high-pressure leaching material is diluted with water and then filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com